Steam room with maximum heating: how to choose a foil for a bath to keep warm

In order for the heat generated from the boiler to remain in the steam room, the bath foil must be used for insulation. How to choose it, what are its performance characteristics and much more in today's publication will tell the editors of homemaster.techinfolux.com/en/. You will also learn about the advantages and disadvantages of this material.

The content of the article

Foil layer for a bath: its functions and features

Woe builders have always believed that from foil when arranging a bath no use whatsoever. Nevertheless, this opinion is erroneous, and with the right approach to its installation, you can achieve a special effect.

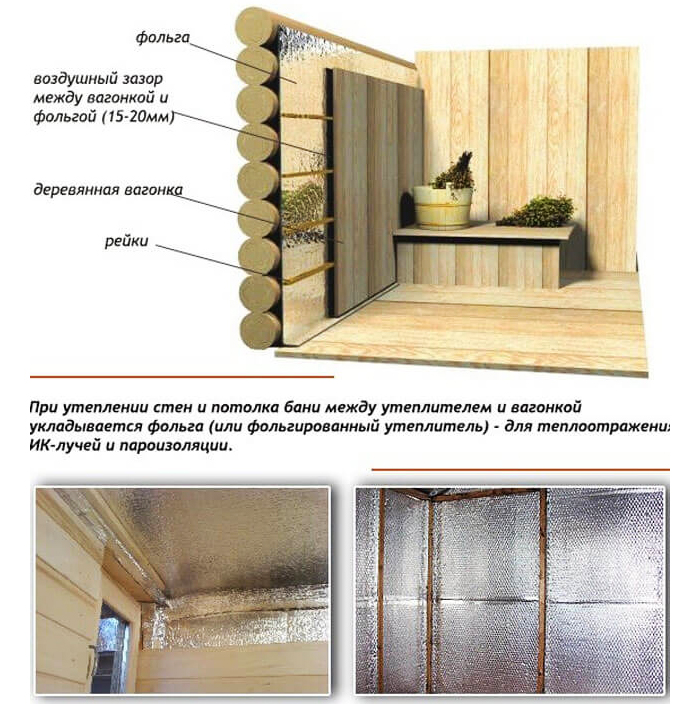

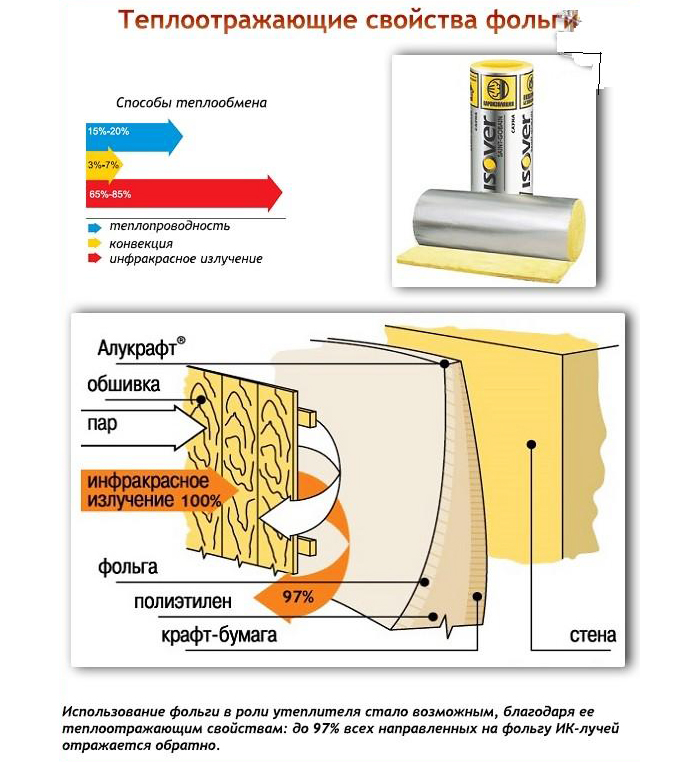

In fact, foil is a thin layer of aluminum. When attaching it to the walls under the wood sheathing, all the heat generated by the boiler reaches the surface and is reflected back. Thus, all the heat energy remains in the room. This layer is used together with insulation or separately. The corresponding material is capable of reflecting about 97% of the heat generated oven.

When buying foil for a bath, you need to make sure that its canvas is intact, without perforation

PHOTO: skif53.ru

Related article:

Bath interior decoration. Photos and examples. In a separate publication you will find interesting ideas for decorating steam rooms and rest rooms, as well as learn the main stages of installation.

Reflector types and performance characteristics

There are several options for foil reflectors, which are usually used when arranging a modern steam room. Let's consider which of them are used in practice, which have operational features.

Izolar craft foil: what kind of material, its characteristics

Kraft foil is a kind of aluminum sheet. It is manufactured with a seal that makes its structure simpler. Differs in the following technical features:

- environmentally friendly material;

- insulator thickness - 0.03-1.0 mm;

- working temperature - 100 ° C;

- reflectivity - 95%.

This material variation is very convenient for installation. It is distinguished by increased strength compared to ordinary foil, which has no base.

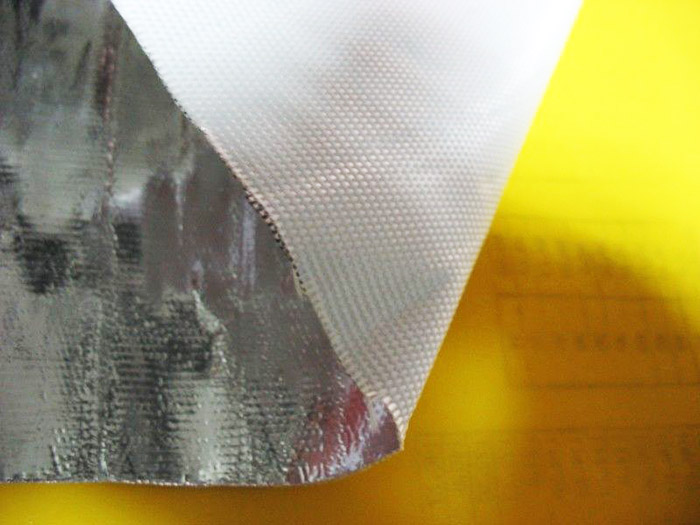

Usually the material has a pimpled base. Smooth seamy side is occasionally used

PHOTO: m.bud.inforico.com.ua

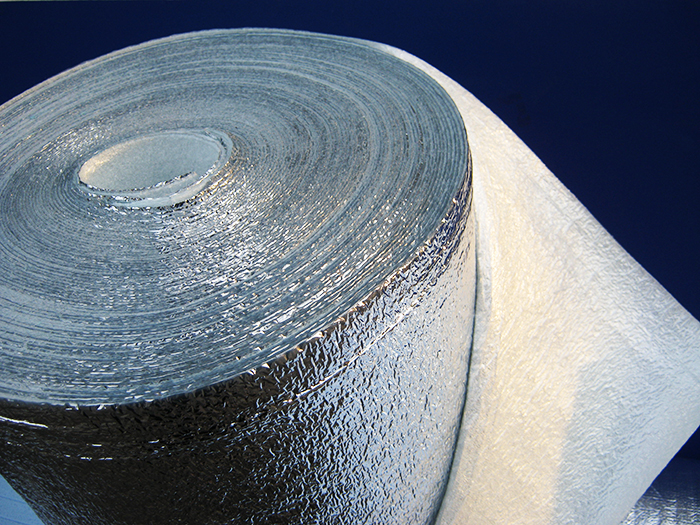

Folmot cloth as an option for thermal insulation

Folded fabric is a special structured foil. It is designed for installation in the ceiling area of the steam room. At the heart of the material there is a heat cloth and aluminum foil. The characteristics include:

- width - 100 cm;

- foil thickness - 11-35 microns;

- working temperature - up to 500 ° С;

- suitable for replacing fiberglass.

When heated, this material does not emit toxic substances and an unpleasant odor.

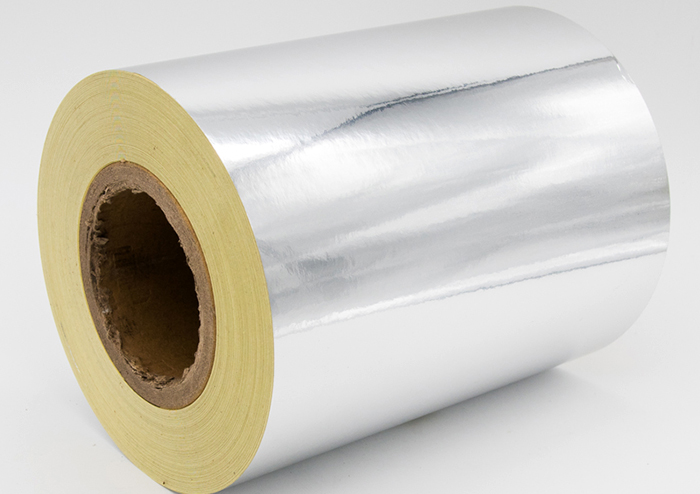

What is roll foil

As a rule, roll foil does not have a reinforcing base. This is a fairly thin material that easily tears and deforms. Its technical characteristics are:

- thickness - 0.007 - 0.2 mm;

- width - 100-150 mm;

- operating temperature - 650ºС;

- thermal radiation - up to 97%.

Does not emit toxic substances, and also resists corrosion.

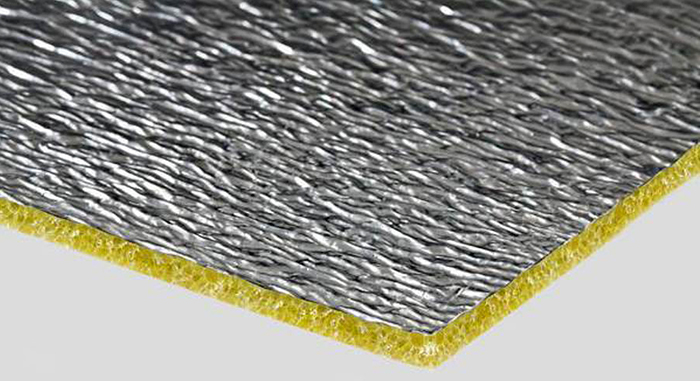

Foil polyethylene foam

The basis of this raw material is foamed polyethylene. They try to use it to retain heat energy in homemade baths and saunas from a wooden frame. Occasionally used for soundproofing cars. The main technical characteristics are as follows:

- coating thickness - up to 15 microns;

- has a low dynamic resistance;

- laying method - overlap by 10 cm;

- holding of working temperature - 300 ° С.

To fix this material, special metallized tape and wooden slats are used.

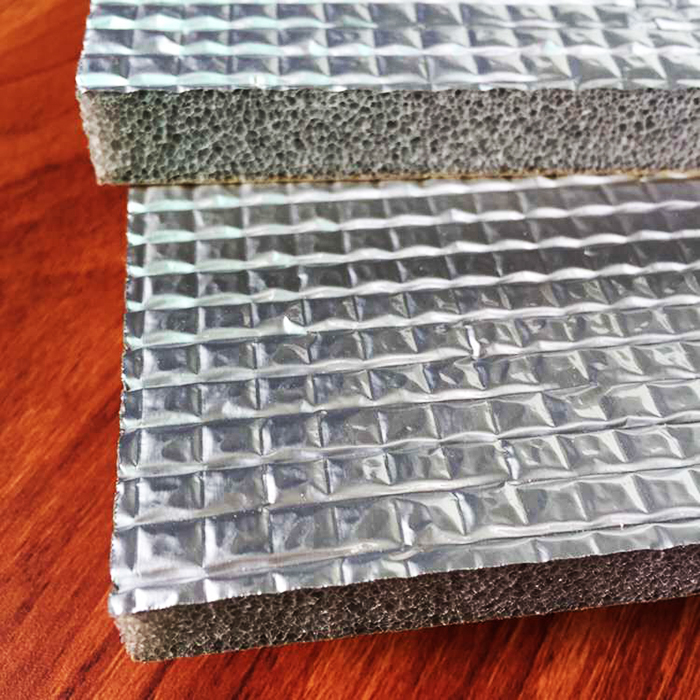

Foil polystyrene foam

Material with foil on both sides. Such a coating is able to prevent heat from leaving the room and prevents moisture from entering. Its features are:

- porous or corrugated structure;

- high resistance to external loads;

- ease of installation and operation;

- unpretentious care.

However, you should not nail the canvas with nails with a too large cross-section, as this can damage the insulating material and lose its quality.

Foil mineral mat in mats and rolls

Manufactured in the form of slabs and rolls. Differs in increased property of thermal insulation. Suitable for baths, saunas and industrial steam rooms due to its high temperature resistance. Material characteristics are as follows:

- thickness - 5-100 mm;

- variable length and width;

- heat reflection - up to 97%;

- operating temperature range - from -60 ° C to 300 ° C.

On a note! There are a large number of foil materials, one of the most expensive is the "ISOVER Sauna" heat insulator. It is suitable for use in specific conditions, as it has all the necessary characteristics.

Advantages and disadvantages of the material

Foil usually comes with a different type of insulation. It is rational to mount it in combination with glass wool and other denser materials. Subject to these conditions, the material will have the following advantages:

- Vapor barrier and thermal insulation - due to this, hot steam does not pass into the middle of the insulating material, thereby preserving its properties, as well as the heat inside the room.

- Fire safety... The material can withstand high temperatures and is non-flammable. Prevents the spread of fire to other walls.

- Possessing good sound insulation properties... It suppresses noise from the street and from inside the steam room by almost 70%.

- Reducing the heating time of the bath... Properly equipped interior wall insulation will allow heat to fill and retain the steam room faster.

It is better to use only special tape for pasting. Ordinary tape will not support the weight of insulation

PHOTO: potolok-exp.ru

Despite the large number of advantages, this material is not without its disadvantages. These should include:

- constant formation of condensation;

- you cannot do without ventilation equipment;

- poorly penetrating air, which can cause dampness and mold;

- the poisonous properties of aluminum (this metal is capable of heating up in the body).

Proper care of the room, its regular ventilation can reduce all the disadvantages to a minimum. Therefore, after each bath, do not forget to open doors, windows and vents.

Which foil manufacturer can you trust

There are a sufficient number of brands on the building materials market that specialize in the production of foil insulation. Among all, three manufacturers can be distinguished.

- Izolon... The concern is located in Izhevsk. Specializes in the manufacture of foils and plastics. For the production of insulation, special technologies are used. The material is produced both sewn and not sewn.

- Penofol... This manufacturer produces thin material with no backing. At the same time, the structure is sufficiently strong and reliable.

- URSA... One of the leading manufacturers in Spain. He produces high quality insulation of various thicknesses and structures. This insulator is also sold in Russia.

When choosing a brand, attention is paid to those brands that promise high quality and compliance with all GOSTs.

The remnants of foil-clad cloth can be used in places where the thermal insulation is damaged

PHOTO: klevo.net

Rules for choosing a foil for a bath

Having studied all the possible options and characteristics of foil-clad materials, you can make the right choice. To do this, you need to consider a few simple criteria.

- It is better to give preference to foil with a backing. It is easier to install and more efficient in operation.

- As for the operating temperature, the model of the canvas must have indicators of at least + 100 ° C. Otherwise, in the steam room, the material will begin to deform (fortunately, this is rarely seen).

- When buying, it is advisable to analyze the seller's opinion about the material you like, moreover, you can also read reviews of real users.

- When purchasing a material in combination with a substrate, it is important to be aware of its thermal resistance.

- The permeability of the foil, with or without backing, should be no more than 0.01 g / m².

As for the thickness of the material, it all depends on how much the bath needs insulation. If the room needs to be insulated from the loss of heat energy, then you can do with the usual thin heat-resistant foil.

Foil for a brick bath

Brick walls do not have good thermal insulation, as they have gaps between the seams. For such premises, foil-clad canvas is used throughout the entire area. Fits directly onto partitions. A small space is left, after which the crate and sheathing are made. Therefore, it is better to buy material with a thick backing.

In a steam room with concrete walls

The usual aluminum modification is not suitable here. In this case, it is better to use options with some kind of substrate. This allows you to achieve effective vapor barrier, reduce the risk of dampness in the walls.

Popular insulating foil models

Many people prefer not so much the brand as the version of the material they like. It is often chosen for its external features and performance characteristics. The homemaster.techinfolux.com/en/ editorial board offers an overview of decent models.

Foil Installation Tips

It is clear how to attach the foil to the walls of the steam room. However, the following tips should not be neglected.

- For the installation of insulation, it is necessary to install a separate crate.

- Thick enough foil sheets are best glued joint to joint using aluminum tape.

- Damaged canvases must be sealed with the same tape.

- Insulation and cladding should not be done closely. It is important to leave a distance of at least 3 cm between the materials.

- Insulation near the windows must be measured close, and after installation, paste over with sealed tape around the frame perimeter.

Observe the installation requirements and be guided by the performance characteristics of the material when using it. Also ask questions about the topic of the publication and do not forget to rate the article.