Well plastic rings: scope and characteristics

Well in the yard or in the country it often becomes the most accessible and functional element that allows you to establish an autonomous water supply. Concrete rings are gradually becoming a thing of the past, and they are being replaced by plastic well rings. The new material leaves no doubt about its strength and reliability. It serves for a long time, is not susceptible to corrosion and is lighter than concrete structures. Often plastic rings are used for repair wells... Let's find out which materials should be given preference, focusing on their types and characteristics.

The content of the article

- 1 What are plastic well rings for?

- 2 Areas of application of plastic rings for wells

- 3 Sizes of plastic rings for a well: material prices

- 4 Overview of the constituent elements of a plastic well

- 5 Comparison of the mass of plastic and concrete rings for a well

- 6 Prices of plastic rings for a well

- 7 Conclusion

- 8 Video: installation of plastic well rings

What are plastic well rings for?

Not so long ago, reinforced concrete rings with a low height were especially popular, which contributes to better tightness of the structure. But over time, the quality of the seams becomes worse. This problem was perfectly solved by plastic water wells. They are often used for arranging drinking springs. Polymer rings are known for their excellent strength properties and are designed to last 50 years. In workshops, rings are made from polypropylene or polyethylene. These types of materials have remarkable inertness and resistance to various chemical elements. High-tech material does not lose its properties even with temperature jumps from -70 to +50 degrees. Therefore, you can not be afraid that harmful components are released into the water.

Let's find out what are the advantages of plastic rings for a well:

- weight. This parameter is the most important, since the low weight does not create difficulties with moving and installing the system;

- the size. The plastic ring is 1500 mm. Other sizes can also be ordered;

- ease of installation. Installation is carried out without the involvement of special equipment;

- tightness of all connections. Any element is equipped with a threaded connection, which ensures watertightness, as well as the absence of contamination;

- material strength. The plastic is designed for a pressure of more than 0.5 bar.

In wells made of plastic rings, additional elements are provided, such as transitions for the hatch, bottom and cover. They are made of polymer composite materials. Hatches can be made of plastic. This material is versatile and has good resistance to aggressive substances.

Polypropylene is even more durable. It is used for various repairs, even in difficult climatic conditions. The most wear-resistant material is fiberglass.

Areas of application of plastic rings for wells

The joints of concrete parts are sealed with a special cement mixture, which can crack over time. Due to the solidity of the products, rings for a plastic well are devoid of this problem. High tightness makes polymer tanks safe. They are installed as ready-made structures or as an addition to concrete shafts. In the latter version, they act as a sealed insert that prevents any leakage of liquid. Polymer tanks are in demand when you need to connect the mains of the sewer system.

Plastic elements are used in such structures:

- for sources with drinking water;

- for sewerage systems;

- for drainage systems;

- for stormwater installations;

- for the installation of sewerage at industrial enterprises;

- for the repair of already working wells.

Prefabricated systems can be installed to a suitable depth. Be sure to use a lattice or blank cover. This will protect against the ingress of foreign substances inside.

Note! Prefabricated structures are assembled into a single whole by means of a thread. This makes the installation very fast. Before connecting, the threads must be lubricated with silicone sealant. The sections can be easily replaced if necessary.

Related article:

Plastic drainage well. In this review, we will consider the types, types, design features, how to make a concrete well with your own hands, how to clean it, a review of manufacturers, average prices.

Using a plastic well for drinking water

When purchasing a country house or summer cottage, there is often a problem with access to drinking water. A practical solution is polymer well rings. The potable water design assumes the installation of a seamless pipe.

Installation of plastic rings for a drinking well is carried out after finding the aquifer. In some cases, the exploratory drilling or dowsing method is used. Then, in the right place, the excavation will be carried out. Moreover, its diameter should be 15-20 cm larger than the diameter of the prepared pipe. Digging is carried out before water appears. Then the plastic insert is mounted. After installing the plastic structure, the space between it and the walls of the pit is filled with sand.

Before the water can be used, the pump must be lowered to pump out the water. This is done until the water becomes clear.

When creating these types of wells, the following materials are used:

- polyvinyl chloride. It is a thermoplastic polymer. It does not ignite in open space. If special protection from environmental phenomena is required, then this material is selected;

- polyethylene. The material has a high density.It is not exposed to aggressive environments and does not react with salts and alkalis;

- polypropylene. Produced by the polymerization of propylene with the action of catalysts. This material has higher melting parameters than polyethylene.

The video shows how to quickly install a well:

Important! To ensure tightness, a rubber seal is used. But this material must be of high quality.

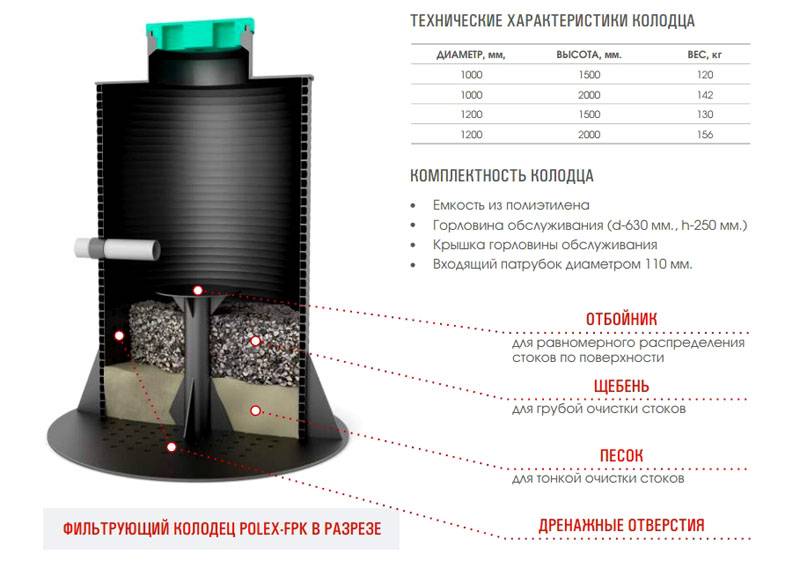

Features of plastic wells for sewage

Plastic structures are suitable for installing a sewer system. Most often they are used to connect different lines, as well as to change the direction of the pipe. When purchasing polymer wells for sewage for drainage of technical waste, it must be borne in mind that the material should not be influenced by organic solvents.

Has features a sewer tank device. This is a cylinder-shaped container, at the bottom of which there is a special pipe tray.

Consider the most popular design options:

- revision and tray are relevant for branching or turning networks. They are needed for various connections as well as for easy maintenance. In the center there is a tray element, which is performed with a slight slope, which protects the system from the accumulation of drains;

- sediment wells mounted in free-flow systems or at branching areas. It consists of a container with branched pipes, the bottom being placed well below the level. They are used to collect precipitation;

- differential devices suitable for gravity systems. They affect the rate of movement of wastewater;

- inspection used for the installation of various locking and regulating equipment. The device assumes a completely sealed container, and a staircase is provided for the mine;

- eccentric options necessary for checking pipes of significant diameter, for storing water or for installing different pumps;

- storage wells Are sealed containers for pumping wastewater.

What is a plastic well for a well for?

Not so long ago, the use of plastic equipment for wells was considered unacceptable due to the fragility and unreliability of the material. But the possibilities of modern technologies make it possible to create especially durable structures of plastic wells. The plastic elements include polypropylene, non-plasticized PVC, polyethylene and fiberglass. The combination of these materials provides the tank with extra strength.

There are certain advantages to using plastic structures:

- ease of repair;

- significant operational periods ;;

- excellent thermal insulation performance;

- the use of plastic wells is a more affordable solution in financial terms than the use of structures from other materials;

- high-quality material retains all the necessary characteristics throughout the entire service life;

- using plastic caisson you do not have to waste time installing waterproofing.

Sizes of plastic rings for a well: material prices

Prices depend a lot on the size of the well rings. The cost of a section is influenced by its wall thickness and diameter. For example, rings from the Ekosis company with the following dimensions: outer diameter - 950 mm, inner - 900 mm, height - 1500 mm - cost 9 thousand rubles. And with diameters of 600 and 650 mm they have a price of 8 thousand rubles.

At Rodlex, rings with a height of 500 mm have a price of 4.3 thousand rubles, products with a height of 1000 mm - 8.7 thousand rubles, and a height of 3000 mm - 25.9 thousand rubles. The cost of other parts of the well must be additionally specified.

There are standard well ring sizes. The parameters of the inner diameter vary between 60-90 cm, and the outer diameter - 65-95 cm.The height is usually 150 cm.The cover is selected in accordance with the parameters of the well.

Selection of the diameter of plastic rings for wells

An important parameter is the diameter of the well ring. It affects the capacity of the planned structure.

| Diameter types | Parameters, mm |

|---|---|

| Inner diameter without bottom | 900, 800, 680, 600 |

| With the bottom | 900, 800, 680, 600 |

| Outside diameter without bottom | 950, 850, 730, 650 |

| With the bottom | 950, 850, 730, 650 |

When choosing a plastic well 800 or with a different diameter, it is necessary to take into account the parameters of the cover. This element has an inner diameter ranging from 550-900 mm, and an outer diameter of 600-950.

Dimensions are selected when creating a structure project. The parameters directly depend on the purpose and operating conditions. The wall thickness does not depend on the section parameters. It equals - 25 mm.

Height of plastic rings for wells

Standard sizes of well rings are 50-150 cm. Moreover, the higher the height of the well ring, the more the product will weigh. Polymer-sand rings are made with a minimum height parameter. This allows installation work to be carried out alone and without any equipment. Rings with non-standard parameters are produced in special productions. In this case, a suitable well ring height can be ordered.

Overview of the constituent elements of a plastic well

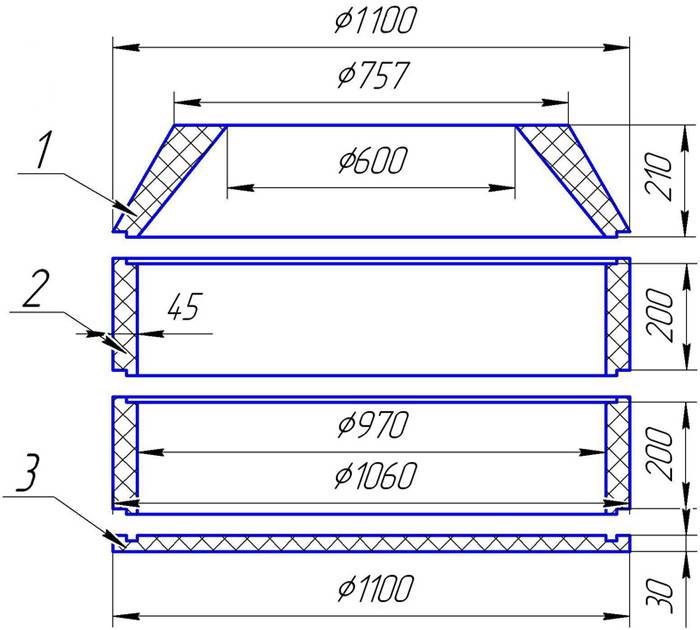

The plastic well has a simple design. Most often these are three details:

- neck installed flush with the ground. It provides access to the internal reservoir of the well. A hatch is installed on it;

- mine represents the biggest detail. It connects the base of the structure and the shaft;

- tray used for installing pipes, as well as for directing drains.

The neck can be tapered or cylindrical. The first option is used when the shaft diameter is much larger than the standard hatch diameter. The telescopic neck is used to install structures at great depths. The cylindrical element is moved to the desired depth and is set at ground level.

There are two types of mine: solid and prefabricated. The first design is easier to install and sealed. The second can be selected for different depths. When installing a prefabricated model, the individual segments are mounted to each other using gaskets.

The bottom element in the well is a polymer tray or kinet. This part is selected after designing the system. From above, the structure is closed with an ordinary cover or hatch. They are made from polymer sand, plastic or cast iron. If there is no neck, then the hatch is attached to the shaft.

Most often, a standard flip cover is used, and on order for a specific neck, a screw-type cover is made. There are also certain requirements for well covers. They must protect the mine from the penetration of debris and foreign objects. The cover must withstand static and shock loads. The diameter of such a part varies between 350-1200 mm, so they can cover a caisson, a well and a septic tank. Polymers make them impact resistant. To select a suitable cover, you need to take accurate measurements of the well head.

How to choose the right plastic pipe for a well

Well pipes are made of polyvinyl chloride, polypropylene, HDPE and PVC-U. There are the following types plastic pipes large diameter for a well:

- with a triangular profile with threads of different lengths. Couplings of certain sizes are used to fix pipes. The thread looks like a cone;

- trapezoidal profile with tapered thread;

- pipe with connectionswith good tightness.

It should be borne in mind that the density of HDPE pipes is 0.95, and PVC-U pipes - 1.4 g / cm³. The calculated voltage is twice as high for PVC-U. The modulus of elasticity has a value of 3000, and for HDPE it is 900.

Due to its high yield point, PVC-U is better suited for threaded connections. In addition, pipes made of this material are characterized by excellent hydraulic properties.

HDPE - experts recommend using pipes for wells up to three meters. And for wells, PVC-U material is more suitable.

Prices for thin-walled polyethylene plastic pipes for drinking water wells vary from 14 thousand per linear meter.

Plastic inserts in the well

Some details allow repairing individual sections without dismantling all structures. To do this, you need to choose a suitable plastic insert in the well. This allows you not to engage in additional sealing of joints. There is a special technology for installing plastic liners in concrete rings.

The inserts are matched to specific sizes. All elements must fit together. To assemble a collapsible structure, you will also need a neck and a cover. Taking into account all the parameters, a plastic bottom for the well is also selected.

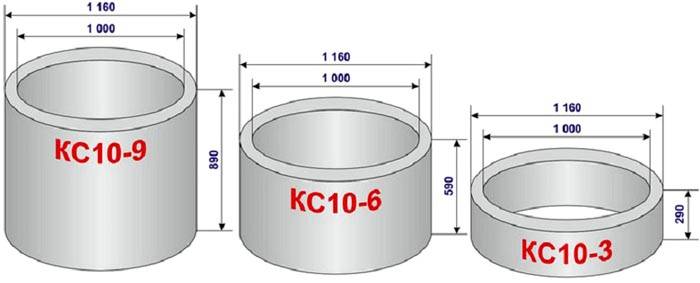

Comparison of the mass of plastic and concrete rings for a well

When creating a project for a well structure, you need to know how much the ring for the well weighs. It should be borne in mind that the surrounding soil can also be with an aggressive environment. An important parameter that must be taken into account is the constant load. It consists of the weight of the structure as well as lateral and vertical pressure. Concrete products are heavier than plastic counterparts. For example, polymer sand rings for a well with a height of 25 cm and a diameter of 100, weigh 60 kg. At the same time, even when installing a prefabricated polymer sand well, even two such elements will weigh 120 kg, which is less than a concrete part - 320 kg.

In the table you can see the weight of the concrete ring depending on the dimensions.

| Diameter, cm | Height, cm | Weight, t |

|---|---|---|

| 100 | 60 | 0,45 |

| 100 | 90 | 0,65 |

| 150 | 60 | 0,72 |

Prices of plastic rings for a well

The price of a section depends on the thickness and diameter of the product. To buy the right plastic well rings, you need not only to study the assortment, but also to select the necessary covers, necks, tees and cones. Their cost should be specified separately.

The table shows the dimensions, prices of plastic rings for a well:

Prices for plastic wells vary depending on the manufacturer and individual characteristics.

Conclusion

Plastic rings are a practical and convenient solution for any type of well. They are becoming more and more popular due to their easy installation and delivery. This is a functional option for giving and personal plots. The designs are in no way inferior to the operational and technological characteristics of their more massive counterparts. The advantage of plastic wells is that they can be used in regions with any climate, as well as in any soil.

Video: installation of plastic well rings