Concrete and plastic drainage well: a detailed guide to selection and installation

Any owner of his house tries to ensure its integrity and safety for many years to the maximum. To do this, first of all, you need to protect your site from excess moisture and excess wastewater, which gradually erode even the most reliable structures. And only a high-quality drainage system can help with this, which allows you to maintain an optimal water balance in the local area, which prevents waterlogging and waterlogging.

The most important element of such a system is a concrete or plastic drainage well. It is his device, installation and characteristics that we will consider in today's review. This design has extensive functionality and special design features that are worth exploring.

The content of the article

- 1 What is a drainage well and what is it for

- 2 What are the drainage wells: types, types, brief characteristics

- 3 Materials and devices for the manufacture of drainage wells

- 3.1 Concrete drainage well: main characteristics

- 3.2 Plastic drainage well: design features

- 3.3 Drainage well with your own hands

- 3.4 Video: installation of a drainage well

- 3.5 Repair of wells with plastic pipes

- 3.6 Cleaning of drainage wells: basic steps

- 3.7 Where to buy a plastic well for sewerage: price, manufacturers, additional elements

What is a drainage well and what is it for

Let's find out why such a drainage well is needed. After heavy rainfall and strong snow melting, water can accumulate on the site. If the liquid does not leave, then it contributes to soil erosion and destruction of the foundation. Over time, high humidity can cause destruction of the building.

To solve such a problem on the site is possible only for storm sewers. In this case, excess water will be collected in the well, and from there it is removed naturally.Such a system will ensure the drainage of melt and rainwater from the roof of buildings and from the surface of the ground.

Where to locate the collection point depends on what the excess water will be discharged through. Here are the main options:

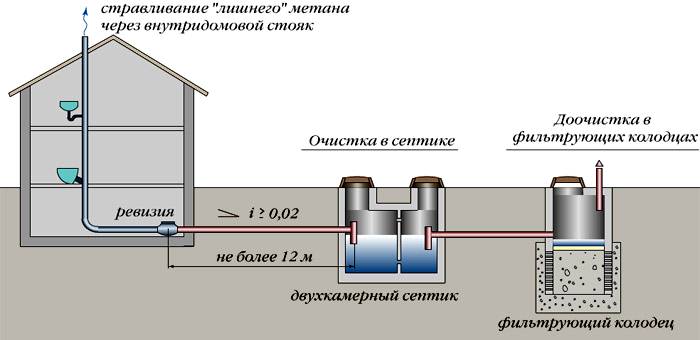

- drainage system in the soil. In this case, the structure is installed according type of septic tank;

- nearest body of water. It can be a lake or a river;

- ravines;

- home autonomous sewerage.

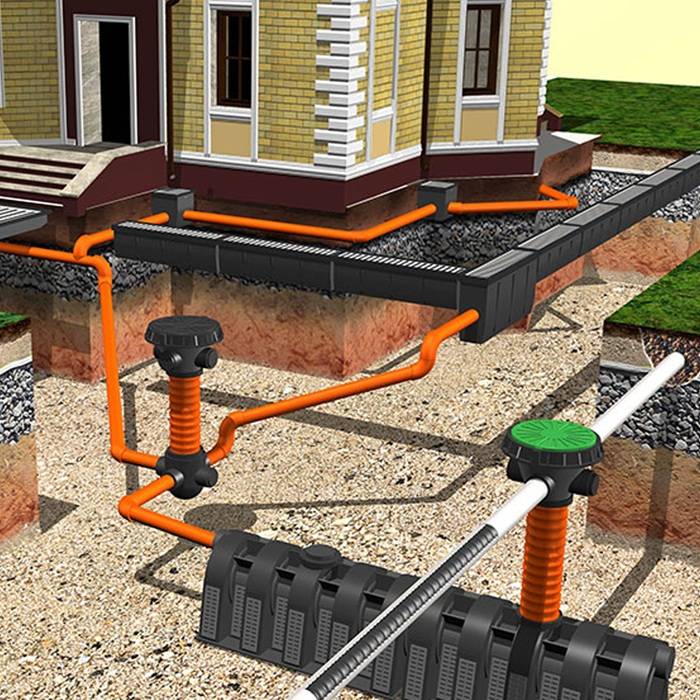

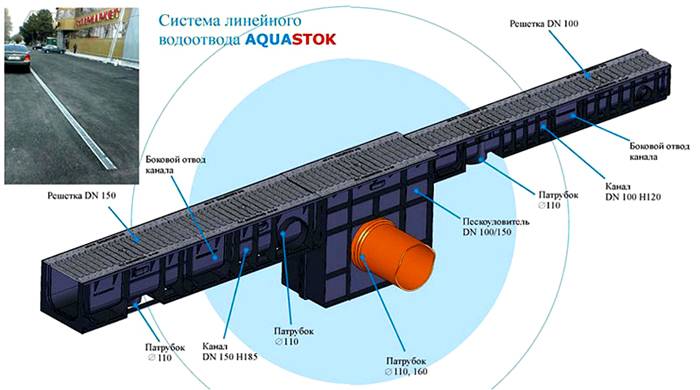

How such a system works depends on the technology of its device. There is a linear type of construction and a point type.

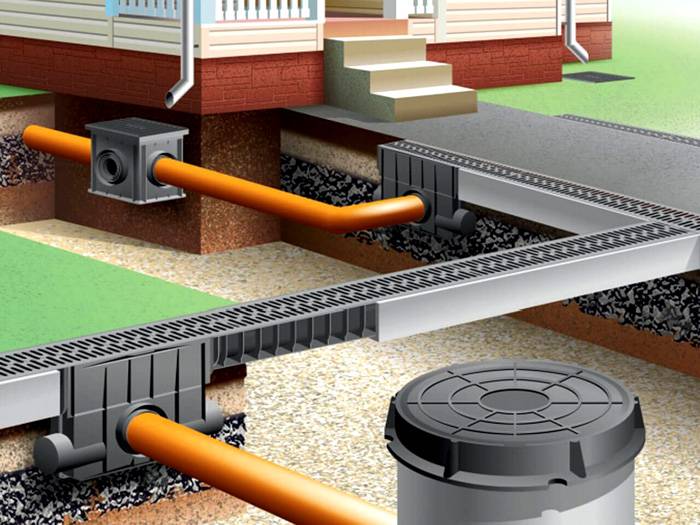

The linear installation provides collection and movement of moisture not only from the roofs, but also on the entire surface of the site. For example, on paths, parking spaces, blind areas. This protects against accumulation of water in the basement at home. There is also a certain plus for groundwater, which does not exceed its usual level.

Spot sewerage is distinguished by the collection of water not in a cone storm water inlet, but into the gutters. Where to install these parts depends on the layout of the site. The receiving chute is installed flush with the paths and sidewalk. This takes into account the slope of the terrain. The structure is covered with grilles and is also equipped with filters. A dot pattern can contain multiple rain receivers. They collect liquid, flowing along the gutters from all the roofs of the buildings. A similar receiver can be made from a barrel. When installing the structure, the distance between the receivers, the optimal depth and the calculation of the drainage time are calculated. All parts are connected into one line, along which the liquid moves to the drainage wells.

It is especially important to establish drainage in clay soil, as even slight rainfall turns it into a swamp. Special attention should be paid to the drainage device for baths... This uses a perforated pipeline.

An important stage is preparation for the construction of storm sewers. In this case, an analysis of the site is carried out:

- a cut is made of the soil layer and its structure is checked;

- the main source of moisture is determined;

- the depth of passage of groundwater is determined;

- the type of construction is selected;

- planning of all wells, trenches and ravines is drawn up;

- the necessary elements and materials are selected. For example, a flap valve.

Related article:

Drainage system around the house: do it yourself drainage device. In the article, we will consider options for a drainage device, how to make a reliable system with your own hands, the average cost of the work of specialists.

What are the drainage wells: types, types, brief characteristics

The classification of storm wells into types is carried out based on the material from which they are made. In this case, the material determines the characteristics of the structure. The most common typical project is represented by concrete and plastic products.

Any well is a container buried in the ground. Here are the main elements of this design:

- bottom;

- plastic shaft or device body;

- Luke.

The shaft is the most important detail. She can represent single chamber septic tank or even a corrugated pipe.

Depending on the purpose, it is worth highlighting the following types:

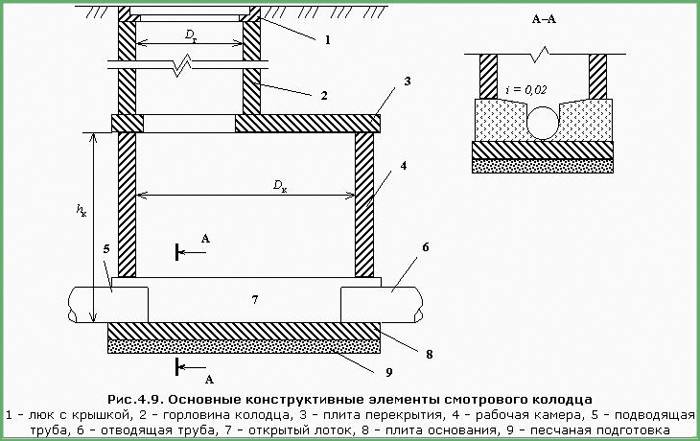

- inspection well. It is also called inspection and whether auditing. It allows you to provide access to monitor the state of the structure, as well as to carry out repairs. Most often, the placement scheme involves its installation on bends;

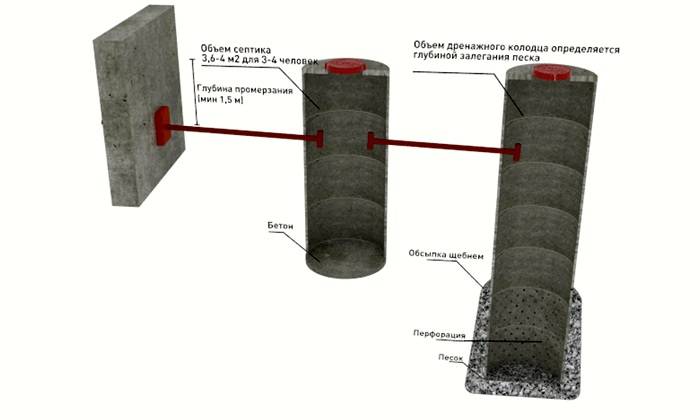

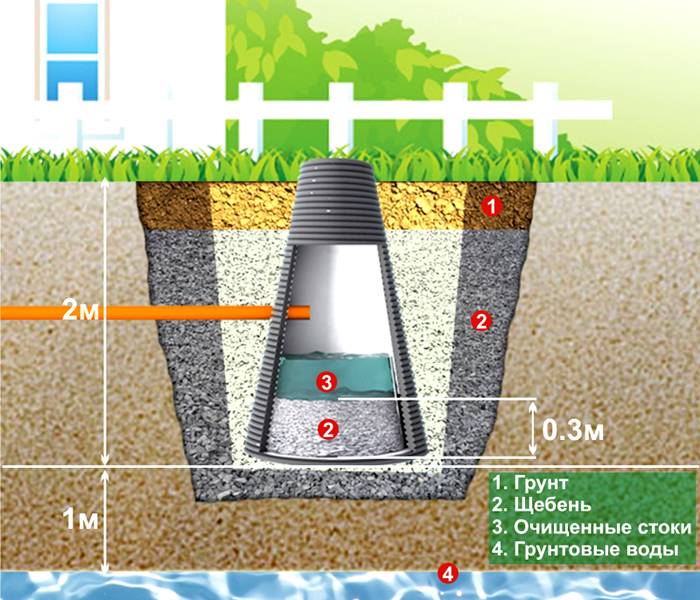

- absorption well or filter with the connection of surface trays, it is necessary in areas where it is impossible to drain water to catchment areas, water bodies or ravines. For its construction, prefabricated plastic rings can be used.This design has no bottom. Moreover, the terrain is dominated by sandy and sandy loam soils;

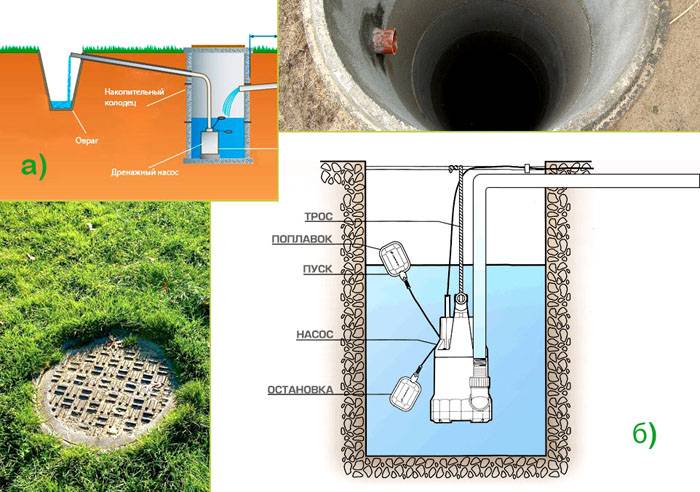

- storage well installed where there is no place for a catchment. In this case, a plastic well with a KDN bottom can be used. It is mounted at the lowest point. The collected water is discharged into water bodies or used for drinking well.

When choosing a design, the size, prices and material of the products also influence. For the manhole and for the bottom, a material such as polypropylene is most often used. Many manufacturers offer hatches for parks, walkways, highways and roads. Certain manufacturers are also important, for example DNEPR. This company manufactures drainage pumps for different wells. DFor plastic structures, materials such as polyvinyl chloride, polypropylene and polyethylene are often used.

Note! The use of a corrugated pipe allows to reduce the load on the bottom of the structure.

Rotary plastic well: design features

Sewer rotary wells are mounted on pipe bends. They allow access to the most inaccessible places in case of blockages. Such pollution is formed from sediments collected under the pressure of water. The installation of such tanks for drainage is recommended at every second bend of the line. These can be where several drains converge or in the corners of a house. For sewage, the size of the rotary tanks is important, which depends on the conditions of their operation. You can buy ready-made designs.

Viewing plastic well: characteristics

Drainage inspection or manhole is designed to check and control the operation of the sewer structure. With its help, you can solve various problems associated with weather conditions or anthropogenic factors. The inspection well must be of a size that allows the inspector to descend inside it. The most common options are 400 x 1000 mm or 315 x 1000 mm. It is important that the diameter is at least one meter.

Such tanks for drainage are often equipped with special sand receivers, in which alluvial soil accumulates. Sometimes a similar option is used instead of a viewing one. If the price for such a structure is too high, then you can consider the option of making a simple well from a plastic barrel.

Accumulative plastic well: design nuances

A collector drainage or storage well is necessary for collecting drainage water and for their further use for technical purposes. The device of the drainage system of a house with storage tanks is allowed in areas with a deep passage of the water intake layer.

Such a water intake well is a sealed container. To make a drainage mechanism, you need to use large diameter corrugated pipes so that a submersible pump for pumping water can fit in them. Additional equipment is used for drainage systems. Therefore, it is important to know how to connect drain pipe with pumping equipment. The price of such installations can be quite high and euro cubes can be used to save the budget.

Materials and devices for the manufacture of drainage wells

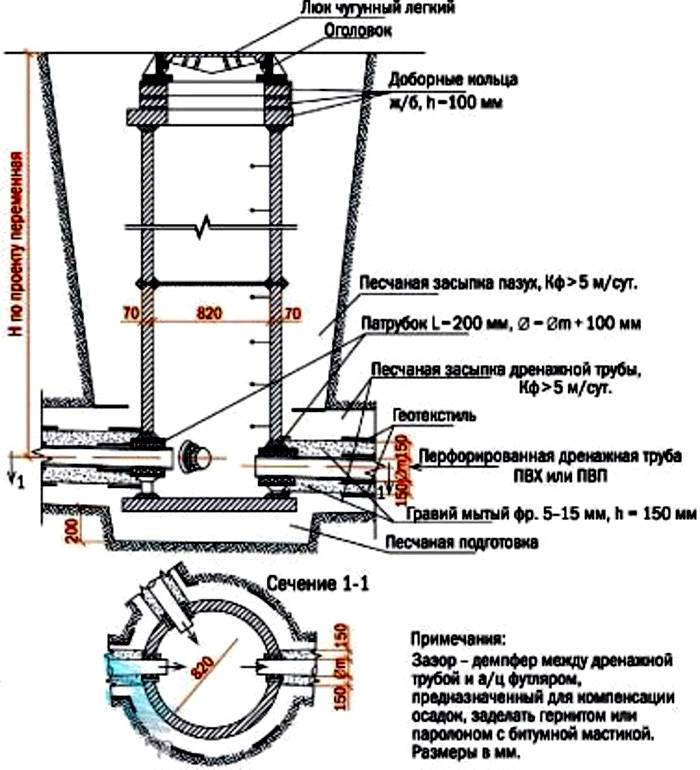

Depending on the type of drainage well, it is necessary to select a suitable corrugated pipe. Here are the main options:

- for a rotary or viewing device, a pipe with a diameter of 0.34 to 0.46 meters is required. It is this size that will allow you to get inside the structure for inspection;

- for a storage or filtering structure, the dimensions should be larger - from 0.7 to 0.9 meters;

- the diameter of the tanks intended for the maintenance of such a system should be from a meter or more.

You will also definitely need rubber seals, a plastic bottom and a hatch to close the hole.

Let's find out what materials are used in the production of such structures:

- concrete products that are difficult to install;

- plastic products are characterized by tightness. They are equipped with cuffs and pipe outlets;

- you can make devices from different materials at hand.

Concrete drainage well: main characteristics

A device made of concrete rings is often used. At the same time, reinforced concrete rings are a common option. These elements can be of different heights and different diameters. The installation of drainage pipes is carried out using special equipment.

How to make such a design depends on the technology used. In the first method, a person is inside the ring and digs a hole, and it settles when deepening. If the size of the elements is small, then first a hole is dug, and then the rings are laid with the help of a manipulator crane.

Concrete wells have the following advantages:

- significant reliability and durability;

- good thermal insulation;

- long operational periods.

The disadvantages include the significant weight of the materials. In addition, concrete can break down in a humid environment. Concrete structures can have plastic inserts, such as plastic covers. Hatches can also have a decorative function.

An important parameter is the price. In this case, you can purchase products from different manufacturers. There are cover designs from Egida.

Plastic drainage well: design features

A sewer well is often made of plastic. This material is excellent for drainage, it actively displaces the concrete version. With proper care, it can be said to be eternal. For sewage, it is possible to make it at home. In this case, suitable pieces are simply cut out, holes are made in them for the hatch and bottom. You can make a drain from a plastic barrel. This method will allow you to get seamless and prefabricated structures.

There are many advantages to plastic structures and are therefore recommended for use around a private home. Here are the main benefits:

- light weight;

- resistance to corrosion;

- not time consuming installation;

- significant warranty period;

- reliability and ease of connections.

Storm structures can be ordered on a turnkey basis. Plastic can be made caisson or use practical septic tank material.

Dimensions and prices are important parameters when choosing wells. Installation costs are often high. Plastic wells can have a different design. There is a prefabricated option. There is also a production of welded structures. Some simple designs are made from plastic bottles. But more often, ordinary high-density polyethylene is used, as well as various types of PVC and polypropylene.

There are different manufacturers of drainage structures. For example, a company Wavin the set includes a system of bottom, manhole cover and corrugated pipe. Also, the filtering conical well is sold by other companies. Firm Matline offers polyethylene wells. The shaft can be in the form of a coiled pipe or corrugated. Prefabricated systems are offered by the company InstalPlast Lask.

There are different product classifications. For example, a model of class A15 means that the element can withstand loads of up to one and a half tons.

For the installation of different structures, special couplings are used, for example, KKT 3. The most popular options include structures with a diameter of 800-1000 mm. Wells Diam 400 are often selected from different models, the price of which depends on the material of the product. Often a plastic liner is used to complement the design. KSK 600 designs with a filtration system are also in demand. The KS 2 and KKS 3 models are also popular.

Plastic manholes and covers for the well

For the sewer drainage well, special hatches are used. How to install the structure depends on the purpose of the storm tank. The hatches are of various sizes and they are marked depending on their purpose. For example, K 3000 - denotes a product for domestic sewage. The optimum diameter of this element is 100 cm. The production of hatches is varied. They can be square or rectangular.

When installing such products, it is important to figure out how to fix this element. The reinforced version is capable of withstanding a load of up to 40 tons. Popular products Egida... Even a decorative cover can be used for the drainage system.

Plastic pipe for a well

Large diameter corrugated pipes are used for the drainage well. The most commonly used products are made of polyvinyl chloride or low pressure polyethylene. PVC corrugated pipe is completely safe for the environment. This material is approved for use in drainage systems. HDPE is able to withstand even low pressure.When choosing a material, the dimensions and prices of structures matter. The cost of products is determined by product quality and manufacturers.

Drainage well with your own hands

How to make a drainage well will be prompted by useful recommendations from experts. How the editing is performed can be seen in the video.

The storm sewer device assumes the presence of such components:

- trays and gutters made of pipes and plastic for water drainage;

- pipes are used for storm sewers;

- storm water inlets with grates;

- storage structures, which are made from plastic pipes, tires, from barrels and even from plastic bottles;

- filtering parts;

- inspection structures.

Before starting the construction of a structure for a septic tank or drainage, it is recommended to study the necessary SNiPs. Vertical installation of storm sewers with a slope, as well as arrangement in a certain place and technology must comply with certain standards.

Table 1. Step-by-step installation of the well

It is also important that the drain pump can be cleaned without problems. To do this, you need to think over all the necessary dimensions. For mounting, you can use concrete or plastic rings. But before that you need to decide on the type of construction. When creating a well from plastic rings, it is necessary to determine the drainage area, the intensity of precipitation, as well as the location of the communication systems.

Video: installation of a drainage well

Repair of wells with plastic pipes

Even wells sometimes need repairs.This is most often evidenced by the deterioration of water quality. It takes on an unpleasant smell and taste. There are many reasons for these problems. A large amount of silt deposits settles on the bottom and walls of the mine. Organic components entering the shaft can affect the tightness of the lining.

The main problem of an old wooden well may be damage to several crowns.If there is a movement of the rings in the well, then the problem can be corrected with the help of plastic rings and heat shrink materials. Also, special sealants are used for the bottom. There is also the production of inserts into the well, which allow you to make high-quality repairs.

In some cases, the connection of the drainage pipe to the well is required. This allows water to be pumped out and cleaned.Deepening with a plastic pipe is required when there is no room for a new well. Only specialists can tell how to deepen the structure.

Cleaning of drainage wells: basic steps

Often, to make repairs, it is necessary to clean and disinfect the wells. The video shows cleaning with a drain pump.

Many people have a question, if the well is flooded, what to do. To determine if it is possible to clean the stormwater system, you should go through the following points:

- first, water is pumped out of the tank;

- after the water is discharged, you need to clean the bottom and walls of the structure with a dark-colored manganese solution;

- if there is a large amount of silt at the bottom, then all filter layers change;

- sometimes a thorough chlorine disinfection is required. The top of the container is covered with a tarp for a day. This requires a full drainage of water from the well;

- the walls must be rinsed several times until the smell of bleach disappears from the water.

An important question is what to do with the water when pumping out. It can be taken to a natural body of water or used for agricultural purposes.

Related article:

Drainage at the summer cottage. The easiest way to drain storm and melt water, types and nuances of installation in a special publication of our online magazine.

Where to buy a plastic well for sewerage: price, manufacturers, additional elements

Before you build a stormwater well, you need to find out how much the installation costs, as well as the cost of individual elements.

Some parts can be purchased separately. For example, it can be a cover with a manhole, a plastic pipe, prefabricated rings or a plastic insert. Decorative covers or large-diameter pipes will cost more. Concrete and plastic products have different prices.

Available from different manufacturers well rings, the price for different models depends on the quality of the material and the complexity of the design. The table shows prices for some products.

Table 2. Average prices for sewerage wells

You can purchase quality designs or make your own. In any case, you need to follow the safety rules and take into account the recommendations from specialists.

To choose a plastic or concrete option, study the characteristics of individual models and the features of their installation will help. Which design to choose is up to you.