Polyurethane stucco molding in the interior and exterior: from selection to photos of examples of finished works

Stucco molding has been used as a decoration for a home since time immemorial. It is this decor item that turns buildings and rooms into works of art. Previously, it was made exclusively of plaster, but now it has been replaced by lightweight, durable and unpretentious synthetic materials. The topic of this article in homemaster.techinfolux.com/en/ is polyurethane stucco molding. What it is, what nuances should be taken into account when choosing and installing - all this is in our article.

The content of the article

- 1 Pros and cons of polyurethane stucco molding

- 2 How is stucco molding made of polyurethane foam, its composition and features of operation

- 3 Types of polyurethane stucco molding

- 4 The best manufacturers of polyurethane moldings

- 5 How to choose polyurethane stucco molding - recommendations of the homemaster.techinfolux.com/en/ editorial office

- 6 A few simple tips for installing polyurethane stucco molding

- 7 How can polyurethane be painted

- 8 Photo gallery of the use of polyurethane stucco molding in the interior

- 9 What does the polyurethane facade stucco molding look like: photo examples

- 10 Price issue: purchase and installation of polyurethane stucco molding

- 11 Video: installation instructions

Pros and cons of polyurethane stucco molding

Polyurethane foam is a fully synthetic material that is produced in a chemical industry. Stucco molding made of polyurethane foam is very light - this greatly simplifies installation. Such products are easy to care for, they are as fragile as plaster ornaments. Synthetics are not afraid of insects, rot and mold.

While describing the advantages of this material, one cannot remain silent about its shortcomings. There are many of them, so you need to immediately imagine what you will have to face. First of all, the synthetic origin of polyurethane foam makes it toxic to humans. It not only emits harmful compounds during combustion, but also "phonite" even at room temperature. Another nuance is that polyurethane foam products dry out over time, that is, after a couple of years you will find joints where they were carefully repaired before.If you have decorated the facade of a building with such a stucco molding, keep in mind that the paint on it will crack, as the surface of the decorations "walks" under the influence of temperature changes.

Another not essential, but obvious drawback is the impossibility of making jewelry to order. That is, if you want an exclusive decor, you should still contact the plaster craftsmen.

And, finally, an important drawback is the high flammability of the material. This is a significant disadvantage that is worth remembering and taking increased security measures.

But do not rush to despair: all the discovered shortcomings are more than compensated for by the low cost and ease of installation. In addition, if you seriously approach the choice of stucco, you can get high-quality products with a protective coating that will not poison the air in the room.

How is stucco molding made of polyurethane foam, its composition and features of operation

The formula for the manufacture of polyurethane foam was invented in the seventies in the United States and has not changed much since then. This material consists of two components, which react to form a foam with air bubbles. To increase the density of the material, the foam is poured into closed molds under pressure.

To manufacture such products, expensive powerful equipment is required. So no handicraft industries produce really high-quality stucco molding, only large companies with a high technological level and competent specialists can do this. The resulting workpieces can be sawed, processed with emery, and nailed. It is strong enough to be used on facades.

Types of polyurethane stucco molding

Figured decorations are, in fact, small architectural forms. They must match the chosen interior style. With the help of beautiful stucco molding, you can skillfully hide the exits of communications or the flaws of the builders. Do not get too carried away with stucco decorations, overkill threatens with bad taste.

Use of such decorative elements must be strictly dosed and proportional to the dimensions of the premises and buildings.

What types of polyurethane stucco molding can be used for the facade of the house

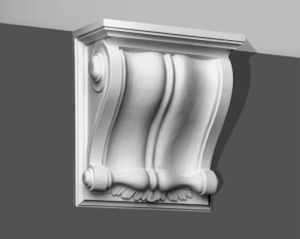

Stucco elements traditionally decorate facades in classical styles. Each historical direction has its own types of decorative elements. Leaves, rosettes and bas-reliefs are collected in holistic compositions. What can be used on a building facade?

Any of the listed types of polyurethane stucco molding can be purchased from the catalogs of large manufacturers. In addition, other elements are presented in them: balusters, bas-reliefs, frames, mascarons, garlands.

Decorative polyurethane stucco molding in interior decoration

Stucco molding in the interior is used in much the same way as in the design of the facade.Eaves are mounted at the junction of the ceiling and walls. They can hide the place where curtains, chandeliers or wall lamps are attached.

Moldings fit perfectly into the design of fireplaces, arches and ceilings. They are placed as framing niches and mirrors, used for zoning. Columns and semi-columns in rooms are usually purely decorative. Such decorative elements have a small diameter - up to 35 centimeters.

Polyurethane skirting boards are rarely used. Most often, the baseboard is selected for the floor covering. But if the design requires just such a design, there are some on sale. Ceiling molding made of polyurethane is represented by a variety of rosettes for chandeliers.

Quirky, of different shapes and sizes, these elements emphasize the elegance of classic lighting fixtures.

The best manufacturers of polyurethane moldings

As already mentioned, high-quality synthetic stucco molding is the result of high-tech production with specialized equipment. Not all manufacturers can boast of a decent quality material. We have selected several companies for you that you can trust.

Europlast - high-quality domestic polyurethane stucco molding

Europlast is a leader among modern domestic manufacturers of polyurethane foam products. Its designers offer a wide selection of a wide variety of products.

Users note the ideal geometry and reliable joint seams in Europlast products. In addition, such elements have high quality standards and safety, confirmed by the necessary certificates.

Popular foreign manufacturers of polyurethane stucco decoration

Foreign manufacturers are also ready to provide quality products for your choice. Here are the most worthy, according to buyers, their representatives:

- Perfect Is a Chinese company that successfully produces several collections. Perfect polyurethane stucco molding is of good quality and affordable price.

- Stucco molding from polyurethane Оrac Decor produced in Belgium. This design is considered elite and is preferred by fashion designers.

- Malaysian decor from Fabello Desor has a subsidiary production in Ukraine. A wide range of various elements is presented in the manufacturer's catalogs.

- Belgian company NMC has been making polyurethane products since the middle of the 20th century. Now this manufacturer, in addition to traditional decor, offers volumetric wall panels with a 3D effect.

How to choose polyurethane stucco molding - recommendations of the homemaster.techinfolux.com/en/ editorial office

Our editors carefully studied numerous customer reviews and recommendations from interior designers. Based on this research, we suggest that you pay attention to the following points when choosing a polyurethane decor:

- do not seek to save money on these products, as a rule, cheap Chinese-made products are not distinguished by either quality or durability;

- if for finishing you need add-ons, plugs and other additional fragments, make sure that they do not differ in quality and color from the main products;

- examine the joints of the fragments. They must be perfectly flat and consistent with each other;

- do not confuse foam and polyurethane moldings - they are different in density. Don't buy styrofoam.

Consider every piece of decor that you are about to buy, they should be free from scuffs or defects in design

Give preference to products made in Belgium - it is a little more expensive than all the others, but you will not regret the costs incurred.

A few simple tips for installing polyurethane stucco molding

Before starting work, you need to fold the decorative elements in the room and let them lie down for at least a day. Polyurethane foam sticks only to clean and dry surfaces.

Important! Before buying and installing the decor, make careful measurements of the room. This saves you unnecessary costs.

If you need to cut decorative fragments for the installation of polyurethane stucco moldings with your own hands, use a hacksaw for metal with a fine tooth. The decor is glued with two types of glue: docking - for polyurethane and mounting - for polyurethane and concrete or wood. It is convenient to use a glue gun.

For more reliable fixing of elements, especially if work is carried out outside the building, dowels are used. Their heads should be sunk in polyurethane and then putty on these places. After the final fixation of all elements, you need to putty the joints and paint the decor.

How can polyurethane be painted

Colored coloring of polyurethane stucco moldings not only decorates the facade or interior, but also protects the surface of products from atmospheric influences. Remember that the joints of the elements need to be putty, and the traces of the putty can only be hidden by painting.

For painting, give preference to latex, acrylic and silicone paints.You can paint the stucco molding before or after installation. Professionals prefer the first option. After joining the elements, the places of putty are additionally painted over. So, you don't have to try to paint on ceilings and walls so as not to stain adjacent coatings.

Photo gallery of the use of polyurethane stucco molding in the interior

Stucco decoration is traditional for Art Deco, Roman, Greek, Empire and Baroque interiors. Pay attention to the photo, how beautiful ceilings with polyurethane stucco molding look. We have selected for you a gallery of interiors for inspiration.

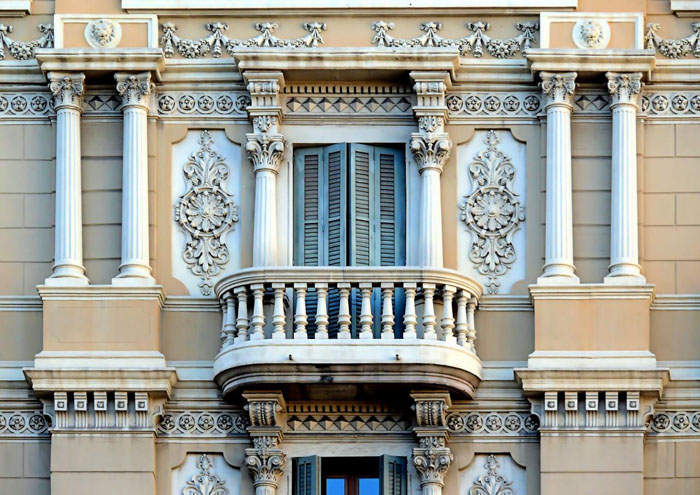

What does the polyurethane facade stucco molding look like: photo examples

The luxury of the interior should have a logical continuation on the facade of the building. The architectural solution of the house with stucco decoration is the result of the work of an experienced designer. It is necessary that the dimensions of the elements strictly correspond to the proportions of the building. The most successful examples are in this gallery.

Price issue: purchase and installation of polyurethane stucco molding

There remains only one question to be clarified: how much will all this splendor cost? Take for example a few basic items and prices as of July 2018. So, a ceiling socket, depending on the size and complexity of execution, will cost you from 2,000 to 5,000 rubles. Curly cornices 2 meters long will cost 900-2,500 rubles. The price of a pilaster is from 500 to 1,500 rubles, a column is 2,000-15,000 rubles.

Now about the services of installers. Installation of the cornice will cost 200-400 rubles, complex elements - about 2,000 rubles. In fact, installing such a decor is not a difficult task, and you can easily save money by getting to work with your own hands.

Video: installation instructions

If you have a similar experience, we are waiting for feedback in the comments!