Greenhouses from arcs with covering material: instructions for step-by-step assembly and the nuances of choosing turnkey greenhouses

Constructions in this category protect plants from bad weather, increase productivity. On the market there are a variety of greenhouses made of arches with a covering material of industrial production. If you wish, you can create a high-quality analogue with your own hands. Which option deserves preference is easy to find out using the recommendations of the homemaster.techinfolux.com/en/ editorial office. This publication contains a lot of useful, and most importantly, verified information for the successful implementation of your project.

The content of the article

- 1 What characteristics should high-quality greenhouses from arches with covering material have?

- 2 Varieties and properties of arches for a greenhouse

- 3 Consumer parameters of different covering materials

- 4 Overview of factory greenhouses from arches with covering material

- 5 Prices and consumer reviews about greenhouses from arcs with covering material

- 6 How to assemble an industrial greenhouse from arcs with a covering material

- 7 Greenhouse manufacturing technology

- 8 Conclusions and additional recommendations

What characteristics should high-quality greenhouses from arches with covering material have?

Such structures are simple in design. Supports are created from arcs with horizontal bridges for better stability. The casing is fixed on top. With its help, they create comfortable conditions for growing various crops.

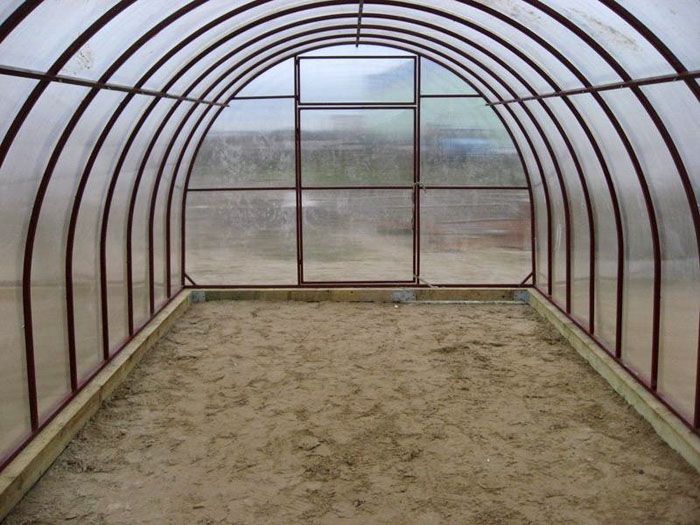

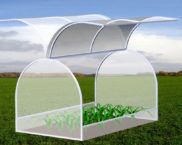

These photos show greenhouse example, which is able to perform its functions all year round when using heating devices in the cold season. Inside you can move in full growth. It provides reliable protection against strong winds and other natural influences. But in practice, compact inexpensive structures up to 1.5 m high are also used.To figure out which option is better to choose, the information below will help. A greenhouse made of arches with a covering material is suitable for the successful solution of various tasks:

- It is used in regions with unfavorable climatic conditions.

- This design is useful for the careful cultivation of delicate seedlings.

- The insulating shell helps you harvest early greens - an ideal source of vitamins for a healthier home diet.

- It also improves the performance of agricultural technologies, prevents damage to plants by pests.

It is easy to guess that in each case a certain option will be preferable. If temporary protection from cicadas is required, a lightweight collapsible design is useful, which can be installed quickly even alone. A stationary structure with built-in lighting and ventilation control is suitable for serious farms.

In any case, it is worth relying on the following characteristics:

- reliability and durability of the power frame;

- transparency, sufficient strength and tightness of the skin;

- fast assembly and dismantling of temporary structures;

- low cost of components;

- simple repair and modernization.

You should also take into account the high humidity in the lowlands. In order not to create complex drainage, it is better to choose a flat or elevated part of the site. It is imperative to comply with sanitary standards for the placement of such structures at a great distance from cesspools and septic tanks... Make sure that fertilization will not pollute the environment, wells and open water. Do not forget about the permissible distances when checking the distances to the corresponding objects in your home and adjacent territories.

Note! In stationary high greenhouses from arcs with covering material, an entrance is made from the south side. This simple technique makes it easier to maintain a high temperature inside, prevents the formation of potentially dangerous cold drafts for plants.

Varieties and properties of arches for a greenhouse

In addition to strength and durability, structural components must be flexible. With a low weight, it simplifies the implementation of assembly operations, movement for seasonal storage. Which arcs are better for a greenhouse can be found out after a comprehensive study of the design, scope. Separately, you should study the convenience and reliability of fastening the skin.

Plastic arches for a greenhouse: main characteristics

Polymer products are not damaged by corrosion processes. They do not have to be additionally protected with paint or other special layers. This significantly increases the service life and reduces the user's household duties.

The picture clearly shows that the cross members bend even with a low weight of the covering materials. The distance between the frames is chosen taking into account the preservation of the overall integrity of the structure. A significant advantage in some situations is the ability to bend parts without damage. It is convenient to work with them without unnecessary precautions, since there is no decorative and protective coating.

Related article:

Do-it-yourself greenhouse made of plastic pipes. A separate review provides a detailed overview of the use, design and installation of PVC pipe greenhouses.

How to use metal arches for a greenhouse

The main advantage of steel products is their high strength. Large durable structures are created from such materials, which are suitable for securing heavy covering materials. Metal arcs for the greenhouse are connected by welding, screws and nuts. The second option provides for the possibility of disassembly.

Building a solid footing increases the overall cost of a construction project greenhouse from arcs with covering material. The protective layers must be kept in perfect condition to prevent damaging oxidative processes.

Features of arches for a greenhouse made of metal-plastic pipes and wood

Products in this category are well protected against corrosion and look great. Polymer-sheathed steel tubes are capable of supporting heavy weight without damage. To maintain the integrity of the surface layers, specialized joints with soft gaskets are used.

Greenhouse arcs made of metal in PVC are more expensive in comparison with the products discussed above. However, for a correct analysis, it is necessary to take into account the characteristics of consumer characteristics. Straight elements retain their original shape with a large distance between the transverse supports. This allows for fewer parts. In this option, there are no costs associated with regular restoration of soil and paint layers. Consequently, operating costs are reduced.

To create high-quality arcs for a greenhouse with your own hands from such material, you need to have professional carpentry skills. Finished products are treated with impregnations that prevent rotting, moisture penetration. They use special formulations that are unable to harm plants and human health.

Related article:

Do-it-yourself greenhouse from a profile pipe. In a separate review, detailed instructions for the design and construction of a structure from a profile pipe are provided with photo examples.

Consumer parameters of different covering materials

After determining with arcs for a greenhouse, it is necessary to find out what is more convenient to make the skin from. Features of typical materials are shown in the table.

| Name | Benefits | disadvantages |

|---|---|---|

| Polyethylene film | Reasonable price, good light transmission, easy installation. | The service life of conventional film models does not exceed one season. |

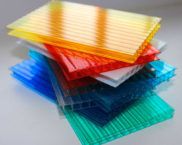

| Polycarbonate | Excellent thermal insulation characteristics, transparency, strength, durability. | High cost, additional costs when performing assembly operations. |

| Spunbond | Lowest price, breathability. Condensation does not accumulate on internal surfaces. | These nonwovens create a blockage to sunlight, which is not suitable for growing individual crops. |

For the right choice, you should carefully read the characteristics of the covering materials you like. In addition to the simplest, they produce modifications of polyethylene films with additives. Such products are more expensive, but at the same time they have better consumer characteristics.

Related article:

DIY polycarbonate greenhouse. Drawings, types of structures, step-by-step construction, advice and recommendations of specialists and much more in a separate publication of our portal.

Overview of factory greenhouses from arches with covering material

To eliminate mistakes when creating homemade products, you can use ready-made engineering solutions. But a really high-quality greenhouse with arcs and covering material can only be bought with a careful study of current market offers. Below are examples of products that have received high ratings from ordinary consumers and members of the expert community.

Model "My Fazenda"

These greenhouses are made of polymer pipes sheathed with a covering material. This solution simplifies assembly, ensures integrity under strong wind loads. The manufacturer offers models with a length of 4, 6 and 8 m and the same section parameters - 1.2 × 0.9 m (Width × Height). When choosing, you must take into account the following features:

- Larger pegs fix the greenhouse more reliably.

- Modified shape without sharp edges prevents accidental damage to the packaging during transportation and storage.

- The product is reinforced with ribs.

- Sheathing - from SUF-42. This non-woven fabric allows water, light and air to pass through. Moisture does not accumulate on the inner surface of the coating.

Removable clips are useful for watering. They are installed at the desired height in order to raise the casing when ventilating.

Snowdrop model

"BashAgroPlast" offers a high-density nonwoven fabric - SUF-60 as standard. The arches are made of low pressure polyethylene. The increased pipe diameter of 2 cm allows you to create a reliable power frame.

The pictures show different options for placing the structure on the land plot. The height and width of the slabs can be changed within small limits. Clips fix the material for creating shade, lighting, airing, watering, and performing other working operations. This protection in a closed structure prevents damage to plants in frosts down to -5 ° C.

Model "Soyuz Techplast"

In this greenhouse, arcs together with jumpers are assembled from separate parts. This solution allows the creation of individual models of high heights. Repairs are carried out without unnecessary costs and difficulties.

On this basis of the greenhouse, you can fix various covering materials. In particular, it is permissible to replace the standard spunbond with plastic wrap.

Prices and consumer reviews about greenhouses from arcs with covering material

The cost of such structures depends on the size and material of which the arched structure and shelter are made. On average, the price differs literally by 100 rubles and varies around 1000.

How to assemble an industrial greenhouse from arcs with a covering material

Each manufacturer provides detailed instructions in the accompanying documentation. With their help, the installation is carried out without the help of professionals. The standard set includes the following products:

- frame elements:

- pegs;

- sheathing (spunbond or polyethylene);

- clips;

- twine.

Explanations for the diagram:

- The parts are removed from the transport package (1).

- Plastic pegs (2) with stop rings are inserted into the ends of the pipes.

- Arches are installed along the bed (3), the material is pulled.

- The soil near the pegs is tamped (4) for better stability.

- Covering material is fixed (5).

- Fix the trim with clips (6).

Greenhouse manufacturing technology

Even a small, relatively simple structure is more convenient to create using a package of design documentation. You should prepare:

- a plan for installing a greenhouse made of arches with a covering material on a land plot;

- design drawing with dimensions of individual parts;

- shopping list (finished products, consumables, tools).

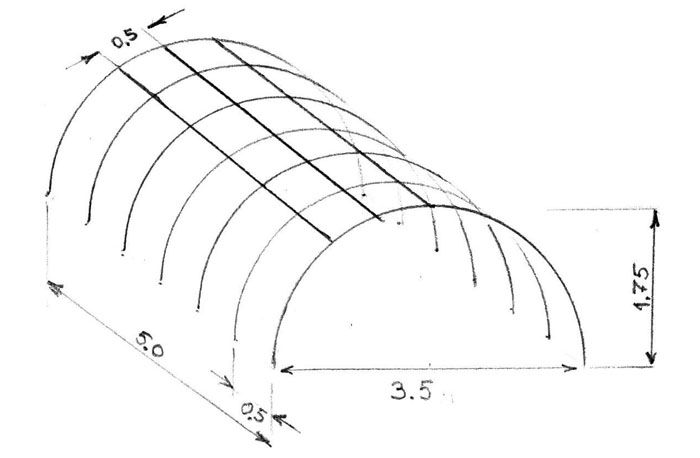

Please note that the distance between the arcs and the longitudinal strips in the greenhouse should not be more than 50-60 cm. A film or spunbond is installed on such a frame. When choosing polycarbonate sheets, the distance between the supports is increased.

In such a design, it is necessary to think over the mechanism for opening the lid and holding it securely in the raised position.

Related article:

DIY greenhouse made of scrap materials. Structural features, the use of various materials to create a reliable load-bearing frame and high-quality cladding, step-by-step installation instructions with the rules for choosing a suitable place on the land are in our publication.

How to make arcs for a greenhouse with your own hands: using different materials

The required rigidity of the original blanks is determined by the size of the structure. For hardening in a plastic pipe, you can insert a metal rod, thick wire, vine, building reinforcement. How to make arcs for a greenhouse from a profile is shown in this video:

The author used a machine made with his own hands. A high-quality frame can be created from water pipes with a diameter of 20 mm. For permanent connection use a specialized soldering iron with nozzles, standard transition elements.

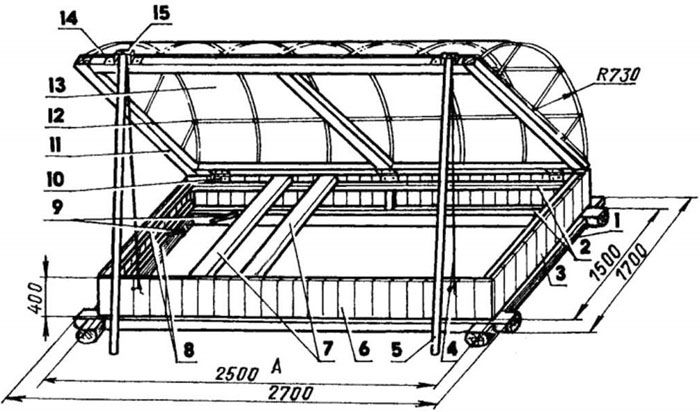

How to install the base and arcs for the greenhouse without errors

Even the factory instructions are for pegs that are not able to provide a secure fit in loose soil. To increase stability, steel bars are driven to the required depth. Pins (10-15 cm) are left on top, on which plastic pipes are fixed. Large structures are installed on a rectangular base of metal channels.

Reinforcement is used for strengthening. When pouring, embedded parts are installed. After the solution has solidified, a waterproofing layer is created from roofing material. A harness made of a wooden beam, supporting and bearing elements of the power frame are sequentially installed.

How to properly fix the covering material on the arches of the greenhouse

If cladding is used, no other fixings are needed. Instead, you can use plastic clips of a suitable size. They are also useful for lifting and fixing material at the desired height.

This video shows how to fix the film on the arcs of a greenhouse without clamping bars and nails:

The author of the project uses horizontal installation of rolls connected by braiding with wire. In any case, it is necessary to ensure a good sealing of the joints.

Note! Strong heating of the metal frame in summer can damage the plastic film. To exclude deformation, insulating gaskets are used or supports are created from plastic pipes.

For soldering straight seams, specialized equipment and fixtures are used or a regular iron heated to the desired temperature

Conclusions and additional recommendations

A shelter for beds on arcs, according to user reviews, increases yields by 50-100% or more. The corresponding investment is justified even when purchasing finished products. It should be noted, however, that some home-made designs are better than factory samples in terms of a set of consumer parameters. Implementation of the project on its own allows you to accurately take into account personal requirements, relief and other features of the land.

Use the comments on this publication for more information. Ask questions here, leave your own advice and comments.

The video shows the process of creating a greenhouse with a frame made of fiberglass reinforcement: