Do-it-yourself greenhouse made of plastic pipes according to an individual project

FROMAmong all types of frames that could be invented for greenhouse construction, plastic ones are the most durable. They do not lend themselves to moisture, which means they are not corroded by mold, they are not afraid of microorganisms and insects. Plastic pipe is an affordable and inexpensive material; parts from it do not require laborious cutting, welding or pre-painting. A greenhouse made of plastic pipes with your own hands is assembled very quickly, and its strength and rigidity depend only on the degree of elaboration of the project.

The content of the article

Plastic pipe as a frame element

Traditional materials for frames are metal or timber, but these materials have significant drawbacks. The timber is short-lived, and the metal is difficult to process. A polypropylene water pipe lasts several times longer than wood and costs half the price of metal. The easiest way to deal with plastic pipes will be those masters who have at least once encountered the installation of water supply systems.

Plastic greenhouses can be made collapsible, because they can easily withstand multiple assembly. Collapsible greenhouses are often not designed for snow load, so they are covered with foil and removed at the end of the warm season. A do-it-yourself greenhouse made of plastic pipes and covered with polycarbonate sheets in winter calmly withstands snow and wind loads. Polypropylene resists ultraviolet radiation and winter frosts equally well, therefore, the frame is not damaged either in winter or in summer.

Features of the use of pipes

The rigidity and strength of a greenhouse depends on its design and the material from which it is made. There are two most common types of pipes on sale - polypropylene and metal-plastic. The first ones have thick walls, bend poorly. The cost of one meter of a pipe with a diameter of 32 mm approximately corresponds to the cost of a running meter of a 20 mm profile metal pipe.

Reinforced-plastic pipes consist of soft plastic and a thin reinforcing metal layer. The wall thickness of a metal-plastic pipe is only 1 - 1.5 mm, so they are easily bent and deformed. As greenhouse experiencing wind load, a plastic material such as reinforced plastic pipe is not a good choice for the frame.

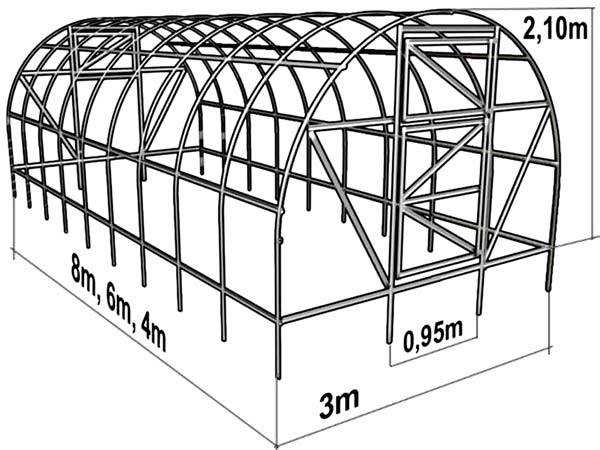

The greenhouse frame consists of several main elements:

- metal supports - pins fixed in the soil or embedded in the foundation of the greenhouse;

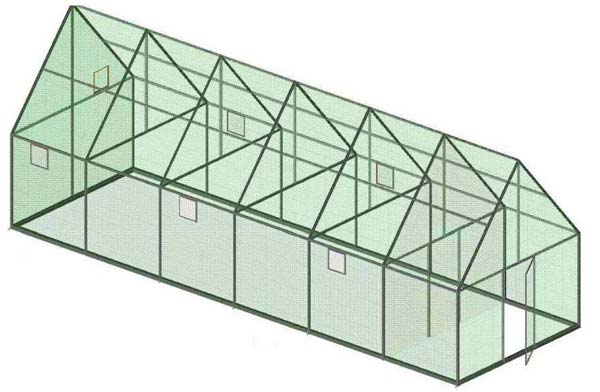

- greenhouse arcs are arched or gable elements made of pipes, polycarbonate or a covering film rests on them;

- stiffeners - elements that are attached between the arcs in a certain order and connect them into a rigid spatial structure;

- doors, vents, transoms are ready-made elements that are hung from the ends of the greenhouse at the last stage of its construction.

The polypropylene pipe is sold as rods of a standard length of 4 meters. The pipe is very elastic and hardly deforms, but it is still possible to bend an arc from it. Stiffeners will be the stronger, the shorter their length. Not only arcuate supports are made of polypropylene, but also gable ones.

Related article:

Do-it-yourself greenhouse from a profile pipe. A separate review provides detailed instructions for the design and construction of a structure from a shaped pipe with photo examples.

Connecting elements

The frame elements are connected in the following ways:

- using standard fittings - couplings, angles, tees and crosses using an apparatus for welding polypropylene pipes, you can rent or buy it, the cost ranges from 3000 rubles and more;

- using fittings of a larger diameter and self-tapping screws, when the pipe is inserted into the opening of the fitting, and fixed in it with a self-tapping screw;

- using self-tapping screws without using fittings;

- using ordinary wire.

The first method is expensive and time consuming, the last two are not reliable. The most widespread technology is number two, when fastening is carried out using self-tapping screws. Such a frame turns out to be very tough and durable, its multiple assembly and disassembly is allowed.

Video: greenhouse frame made of shaped square pipe

Greenhouse design

Before starting the construction, it is necessary to calculate the frame and build a detailed drawing, which will indicate the shape, location, length of the elements, fastening methods and the number of fasteners. A do-it-yourself greenhouse made of plastic pipes, the drawing of which has been worked out in detail and carefully, can be erected in one day.

Typical greenhouse designs are developed taking into account the following factors:

- ensuring spatial rigidity;

- compliance with the width of polycarbonate (if this material is used);

- easy installation with fewer connections.

Related article:

How to make a greenhouse with your own hands from PVC pipes? Detailed step-by-step instructions, practical advice and recommendations in a special publication of our portal.

The height of the greenhouse must be at least 2 meters, otherwise it will not be possible to work in it. The larger the volume of the greenhouse, the easier it is to create a healthy microclimate in it, the less the plants will hurt and the higher the yield will be. The length of greenhouses is usually 3.2 meters or more. This parameter is also associated with economic calculations, because the harvest obtained from a small area does not pay for the construction of the greenhouse itself. Most often, greenhouses with a length of 6 to 10 meters are mounted on personal plots.

The ideal location for the greenhouse is a sunny place protected from crosswinds.In both end elements of greenhouses it is necessary to make one door and one transom, this is necessary to regulate temperature and humidity.

Assembly technology

The erection of the frame begins with the installation of vertical support pins - pieces of reinforcement with a length of 70 - 80 cm. At least 50 cm of this rod must be buried in the soil or reinforced in the foundation structure. A plastic pipe is put on the end of the reinforcement sticking out outward like a hairpin. This type of fastening has proven its strength and reliability, it can withstand strong winds, rain and snow. It is better if the reinforcement is reinforced and its diameter allows you to fit the pipe tightly. The length of the stud should be at least 15 - 20 cm, then no additional fastenings with self-tapping screws are needed.

After all arcs are installed, they need to be connected with stiffeners. First, the central top row is mounted, then the side parts are evenly fixed. Arcs are placed at a distance of no more than one meter, and horizontal stiffeners should have a pitch of 50 - 60 cm.

Doors and transoms are hung last, after covering the greenhouse with polycarbonate or foil. The frame of the door or window is supplied with hinges and locks in advance, and is also tightened with a film (closed with polycarbonate). Completely finished parts are hung from the ends.

Advantages of polypropylene frames

Greenhouses, the frame of which is made of plastic pipes, have the following advantages:

- easy and quick to assemble;

- have high strength;

- durable and versatile.