How to make a greenhouse from scrap materials with your own hands without mistakes

A well-made greenhouse made from scrap materials will increase the yield by 2-3 times. To implement such a project with minimal costs, use the advice of the homemaster.techinfolux.com/en/ editorial office. We have collected the most important and reliable recommendations on the best designs, materials, greenhouse manufacturing technologies, based on the recommendations of specialists and experienced gardeners.

The content of the article

- 1 The main parameters of greenhouses and greenhouses made by hand from scrap materials, with photos and comments

- 2 How to properly place a do-it-yourself greenhouse made of scrap materials on a land plot

- 3 Features of the use of different materials to create a reliable power frame

- 4 What can be used to make sheathing for a greenhouse or greenhouse

- 5 How to make a greenhouse made of wood under a film with your own hands - step by step instructions

- 6 Advantages and disadvantages of homemade greenhouses from scrap materials, conclusions, additional information

- 7 Video: how to make a greenhouse from scrap materials with your own hands

The main parameters of greenhouses and greenhouses made by hand from scrap materials, with photos and comments

Structures in this category are often used in domestic climatic conditions. With their help, they significantly improve yields, fight pests, create convenient conditions for performing work operations. With the appropriate equipment, they organize year-round cultivation of individual crops. Taking into account the intended purpose, it is easy to formulate the basic technical requirements for a suitable structure:

- Good insulation from rain and other adverse external influences.

- Resistant to wind and other loads.

- Sufficient height for plants and comfortable maintenance.

- The minimum cost of the main components of the structure.

In any case, corrections must be made taking into account personal financial and qualification capabilities. Below are considered inexpensive greenhouses that can be built from improvised materials with your own hands without unnecessary difficulty. Detailed instructions explain the specifics of the individual work steps.

With a careful study of photos of greenhouses made with your own hands from scrap materials, it is easy to conclude about the importance of two main components: the frame and sheathing. Their parameters will be considered especially carefully. You should also pay attention to the appearance, which should not impair the aesthetic characteristics of the site. If seasonal reusable use is meant, it is necessary to clarify the disassembly and storage scheme.

How to properly place a do-it-yourself greenhouse made of scrap materials on a land plot

Successfully solving this problem will simplify future operations. If you choose a place taking into account the wind rose, the proximity of buildings and other large obstacles, it will turn out to reduce the load on the greenhouse made from improvised materials with your own hands. The following tips and facts also come in handy:

- Water accumulates in the lowlands, which can adversely affect the cultivation of crops.

- You also need to exclude shaded areas.

- The greenhouse is installed at a great distance from the cesspools and septic tanks.

- A sufficient distance from the well should be chosen so as not to contaminate the drinking water with fertilizers.

- The northern wall of the structure is made closed. The entrance group is installed on the south side.

The mutual arrangement of objects is adjusted taking into account the actual dimensions of buildings and land

Features of the use of different materials to create a reliable power frame

An accurate study of the features of different solutions is possible after the correct formulation of important criteria. The strength of the frame is necessary. Weight matters little. Heavy components are more stable, but difficult to assemble. For long-term use, in addition to ease of assembly, it is necessary to clarify the durability of decorative and protective coatings.

How to make a greenhouse frame from tree branches in the form of arcs for a tunnel shelter

Thick willow rods are strong enough for the construction of large structures. To obtain the required length, several components are fastened with a string. Removing the bark layer beforehand is not necessary if seasonal use is expected. The source material can be obtained at your disposal free of charge.

How to make a greenhouse from building pallet boards

This material is well suited for DIY greenhouses made of wood under the film. Wide, thick boards can support a lot of weight. Large, reliable structures can be created from such blanks. To extend the service life, it is recommended to impregnate with protective compounds. The aesthetic characteristics are enhanced by coloration. The bars are suitable for making a light foundation in the form of a frame along the contour. They are also used as columnar supports.

Standard workpiece sizes simplify assembly operations. If you set the appropriate spacing between the reference lines, you will be able to minimize carpentry operations.

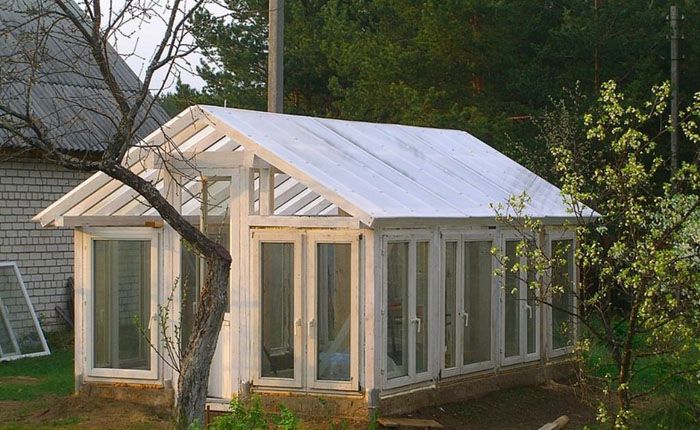

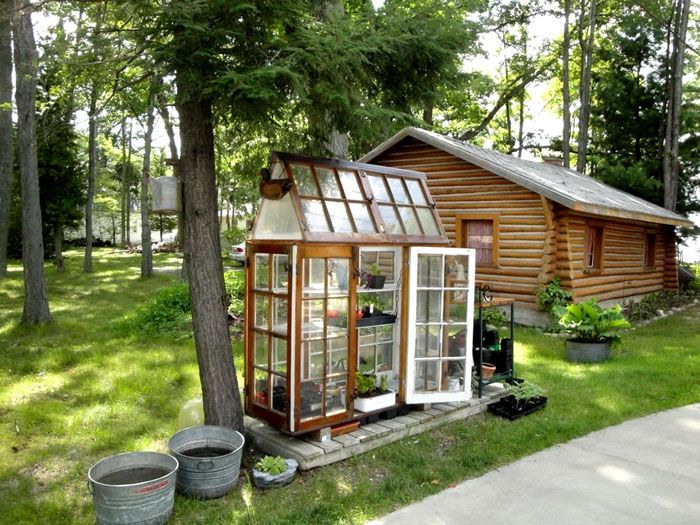

How to make a frame for a greenhouse from old window frames with your own hands

Installation of modern double-glazed windows is economically viable. It reduces energy consumption for maintaining comfortable temperature conditions. But don't rush to throw away your old wooden frames. They are well suited for building a high-quality greenhouse from scrap materials with your own hands. As in the previous example, the standard dimensions of the original products greatly simplify the assembly of a new structure.

These elements are ideal for wall construction. Without new loops and other additional parts, it will be possible to make an entrance group. By opening separate windows, they regulate the fresh air and temperature. An additional advantage is the ease of replacing damaged glass.

The roof is made from other building materials so as not to make the structure heavier. However, even in this version, it will not be possible to significantly reduce the total weight. A suitable type of foundation is used according to the loads. If you install tape, metal-reinforced concrete will provide a long service life.

Note! Longevity is the main advantage of this type of projects. It should also be noted the minimum complexity of the repair, high resistance to various external influences.

Related article:

Do-it-yourself greenhouse from a profile pipe. In a separate review, detailed instructions for the design and construction of a structure from a shaped pipe are provided with photo examples.

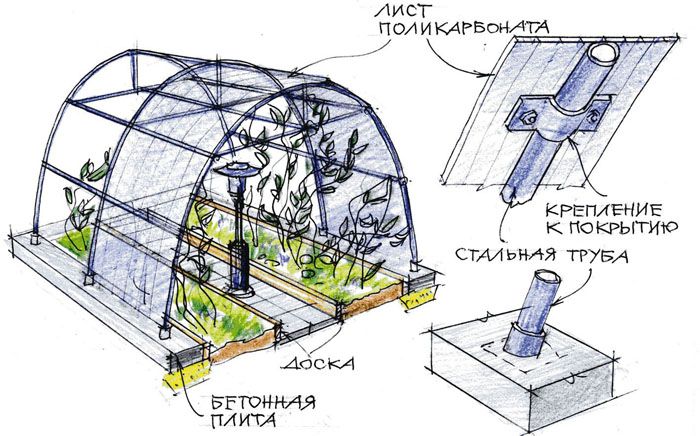

How to create a greenhouse frame from plastic pipes

These products do not rust, look aesthetically pleasing without additional processing. They are lightweight and highly durable. For a reliable and quick connection, you can use standard adapters, fittings of the appropriate size. A small light greenhouse from such improvised materials can be assembled even with female hands alone. Only for large structures you will need a foundation and an assistant to cover the sheathing of plastic wrap.

Related article:

Do-it-yourself greenhouse made of plastic pipes. A separate review provides a detailed overview of the use, design and installation of PVC pipe greenhouses.

What can be used to make sheathing for a greenhouse or greenhouse

As a rule, seasonal use of these parts of the structure is assumed. Accordingly, it is useful to know their characteristics:

- democratic cost;

- ease of installation and dismantling;

- light weight to minimize loads on the foundation and load-bearing frame.

Sufficient strength will increase the distance between the reference lines. It is essential for trouble-free operation outdoors. Do not forget about transparency, which will ensure the flow of heat and sunlight into the greenhouse.

How glass is installed

This material is a “champion” in durability. Its consumer characteristics will not worsen long-term intensive use. Regular washing removes dirt, restores transparency. If necessary, replacement is not difficult.

However, the actual composition of working operations is largely determined by the technology chosen. In the simplest case, glass is mounted in window frames according to a standard technique. Workpieces of the required size are cut out, fixed with wooden glazing beads, and sealed with putty.

Overlapping laying is used on large areas. Fastening between the parts is provided by S-shaped strips bent from sheet metal strips. The side supports are made from a metal corner. The seams are poured with a heated bituminous solution. Similar techniques are used in large greenhouses to create and repair professional-grade structures.

Plating with plastic bottles

This material, in contrast to the previous version, is acquired “automatically”.To prepare a sufficient number of blanks, you need to give a command to family members. Instead of the hassle of disposing of trash, plastic beverage containers will accumulate in the warehouse. Its possible application is illustrated by the following examples.

The same products are used outdoors. They function as a transparent, solid barrier without additional reinforcement and cladding. It is easy to create such a mini-greenhouse with your own hands from scrap materials without detailed instructions. The only but significant drawback is the limited working volume.

The following algorithm is used to reproduce the technology:

- Exactly the bottom parts are cut off.

- By inserting the bottles tightly, they create pillars of the desired height.

- A wooden axle is installed in the central part.

- Attach the blanks to the main frame with self-tapping screws.

- The slots are sealed with tape.

Horizontal stacking of elements is used with a small width of a greenhouse made from scrap materials with your own hands

Bottles can be fixed in the right places using a flexible frame made of strong threads. These products are used to create not only walls, but also greenhouse roofs.

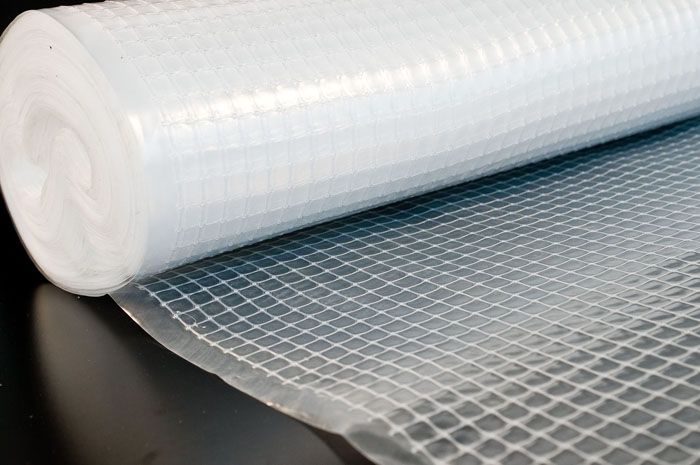

Installation of polyethylene film

For work, choose a material with a thickness of 150 to 250 microns. This is enough to successfully withstand natural stress. Standard products are available in sleeves. When cutting, canvases with a width of up to 6 m are obtained.The following list lists the features of typical modifications of polyethylene film:

- The cheapest is unstabilized. It is purchased for one season (up to 6-7 months of operation).

- With the help of special components, the polymer's resistance to sunlight is increased.

- Special additives prevent the formation and incandescence of condensation, improve thermal insulation characteristics, and ensure uniform radiation dispersion.

Reinforced foils are reinforced with built-in cells. This increases the service life up to 2-3 years.

Note! Modified polymers are more expensive. However, their use is sometimes appropriate. With the help of these products, they increase productivity, provide reliable protection, and improve other characteristics of a greenhouse made from improvised materials with their own hands.

Sheathing with other materials

Instead of fragile glass and insufficiently strong film, sheets are used polycarbonate... These materials are more expensive. But when choosing, one must take into account their special advantages:

- Excellent thermal insulation properties that create structural cavities.

- High strength, shock resistance.

- The ability to create curved and flat surfaces, walls and roofs.

- Durability, preservation of useful characteristics over a wide temperature range.

Soft damping gaskets are installed in the attachment points. Special screws with rubber rings are used to seal the joints.

Important! A significant limitation is the high cost of polycarbonate sheets. It is advantageous to use such materials in the construction of capital structures designed for a long service life.

Nonwovens in this category do not transmit light well. They are used in summer to regulate the microclimate in compact greenhouses.

Related article:

DIY polycarbonate greenhouse. Drawings, types of structures, step-by-step construction, advice and recommendations of specialists and much more in a separate publication of our portal.

How to make a greenhouse made of wood under a film with your own hands - step by step instructions

Start by choosing a suitable location. In addition to the information listed above, it is necessary to take into account the peculiarities of watering, performing other routine procedures.The problems of water supply, laying of electrical networks, additional insulation in winter are solved separately.

At this stage, a suitable design is determined. A greenhouse made of scrap materials with your own hands can be docked with existing outbuildings or the main residential building. Miniature greenhouses are set up for germinating seeds in the open field.

A simple construction is discussed in detail below. A similar greenhouse from improvised means with your own hands can be installed in one daylight. Of course, this requires appropriate preparation.

Necessary tools for making a greenhouse with your own hands

The choice of these components of the project is adjusted taking into account the characteristics of materials, technological processes:

- The marking of the territory is done using twine, tape measure, pegs.

- For excavation work, you will need a bayonet and a shovel. If the site is rocky, a crowbar and a pickaxe will come in handy. The trolley is needed to move bulk goods.

- The workpieces are cut with a hacksaw with a blade for metal / wood, respectively.

- A screwdriver, a stapler, and a hammer are used to fix the power elements and cladding.

- Horizontal lines control the building level.

- The joints of the film are sealed with a soldering iron.

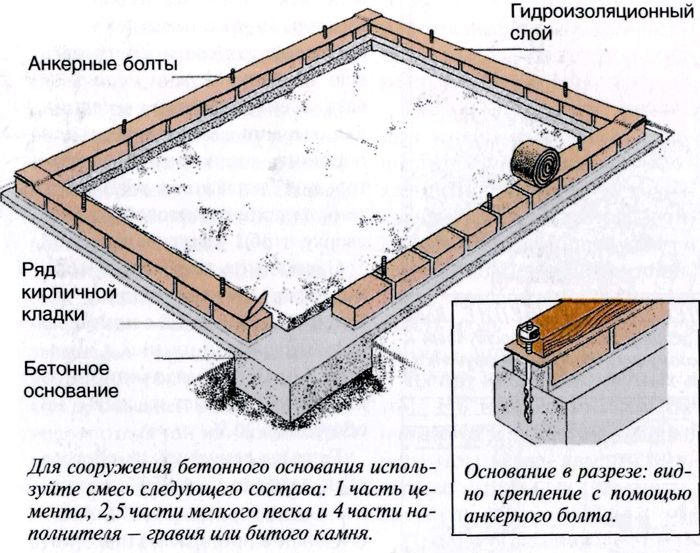

Foundation preparation

The basic characteristics of the project are determined by the specifics of caring for certain crops. For cucumbers, for example, you can apply the following sequence of actions:

- Determine the number of plants, the distance between the rows.

- In a predetermined place of the site, the sod is removed, the pit is deepened by 40-60 cm.

- Creates a drainage layer of gravel or other granular materials to remove excess moisture.

- Organic matter and soil with a total thickness of 25-35 cm are poured on top.

- If necessary, install side walls that keep the shape of the beds.

The photo shows an example columnar foundation... Even on soft soils, it provides the stability of a greenhouse created from improvised materials with your own hands. The vertical supports are installed below the freezing level. Wooden beams are laid on a waterproofing layer.

Installing the frame

It is easy to attach wooden structural components to the support created from a bar. The side walls are made high to provide ease of movement across the entire area at full height. As a rule, a gable roof is used.

Film fixation

In this case, a wooden frame is better than a metal counterpart. It does not heat up in the summer heat and does not spoil the polymer film. If the polyethylene sleeve is not cut, it is possible to simplify the installation operations and extend the service life of the casing. A rope is threaded into the prepared workpiece, thrown over the greenhouse, pulled. Next, install the next part with an overlap of 15-20 cm. Horizontal fastening of the strips is also used.

An iron or a soldering iron with a working surface temperature of +125 (± 5) ° C is suitable for sealing. The polyethylene sheets are laid on a wooden support with a layer of soft material fixed on top. The joints are covered with paper, ironed with a heated tool.

Advantages and disadvantages of homemade greenhouses from scrap materials, conclusions, additional information

Saving money is the main advantage of this solution. During the repair and modernization of housing, it is necessary to remove construction waste. However, some parts of the old structures may well be reused.

With the help of this facility, ideal conditions have been created for the preparation of high-quality seedlings.

The photo demonstrates the original decoration and useful functional equipment of the site - a greenhouse created by hand from frames. Significant shortcomings appear only in case of insufficiently high-quality implementation of plans. To exclude errors, it is recommended to carefully prepare project documentation, shopping list, assembly drawing.

Please ask additional questions in the notes for this publication. Share interesting ideas, leave examples of successful solutions.