Which polycarbonate is best for a greenhouse - recommendations and reviews from real users

What summer resident does not want to have a greenhouse on his site? This question is probably absolutely rhetorical, because in the conditions of our country, especially in the northern regions, it is impossible to get a good harvest of such crops as tomato and cucumber, eggplant and bell pepper, without the presence of a greenhouse or a similar structure. In the manufacture of greenhouses, various building materials are used (wood, metal profile, plastic), and glass, film or polycarbonate is used as a coating. Which polycarbonate is best for a greenhouse: selection parameters and the main characteristics of the material, the advantages and disadvantages of its use, as well as the cost and reviews of real users - the topic of this article by homemaster.techinfolux.com/en/.

The content of the article

- 1 Advantages and disadvantages of using this material

- 2 Types of polycarbonate and what is used for greenhouses

- 3 How to choose polycarbonate for a greenhouse

- 4 Leading polycarbonate manufacturers

- 5 Recommendations for choosing a polycarbonate greenhouse

- 6 Review of prices and user reviews of popular brands of polycarbonate

- 7 Video: how to choose a greenhouse - professional recommendations.

Advantages and disadvantages of using this material

Polycarbonate is a polymer material with high resistance to adverse operating conditions and high light transmittance.

Important! The operating temperature of polycarbonate, depending on the type and brand of the product, ranges from -40˚С to + 130˚С.

Due to its physical properties, polycarbonate is used in various industries (construction, automotive), as well as in the manufacture of products that require appropriate transparency and strength (goggles, shields, sports equipment).

Note! In the manufacture of greenhouses, as a rule, cellular polycarbonate is used.

When sheathing a greenhouse with polycarbonate, its design and shape can be completely different, and the main condition for successful operation in this case is the strength of its frame

The popularity and demand for this material in the construction of greenhouses is due to its advantages, which can be formulated as follows:

- transparency, allowing sunlight to pass through, which is necessary for growing plants;

- flexibility and elasticity - allows you to use on structures of complex geometric and round shapes;

- low weight facilitates installation work and reduces the load on the ground at the construction site;

- high mechanical strength in comparison with glass and film coating;

- the presence of voids (for cellular polycarbonate) in the inner space of the material, filled with air, improves its thermal characteristics, providing low thermal conductivity;

- a variety of colors allows you to create an individual appearance and attractiveness of the created design.

Of course, in addition to the advantages, like any other type of building material, polycarbonate also has certain disadvantages:

- the relative softness of the outer surface can lead to scratches, which will deteriorate the physical properties of the material and even damage it;

- when performing installation work, it is necessary to carefully fasten it to the greenhouse frame: when tightening self-tapping screws or other fastening elements, the polycarbonate surface can be damaged;

- the ingress of water into the internal space leads to the destruction of the structure of the material.

Note! Polycarbonate with a color other than transparent has lower strength characteristics.

Types of polycarbonate and what is used for greenhouses

As mentioned above, polycarbonate is used in various industries, including construction, due to its physical properties.

By its structure, polycarbonate is of two types:

- monolithic - is a homogeneous material produced in different dimensions (length, width, thickness);

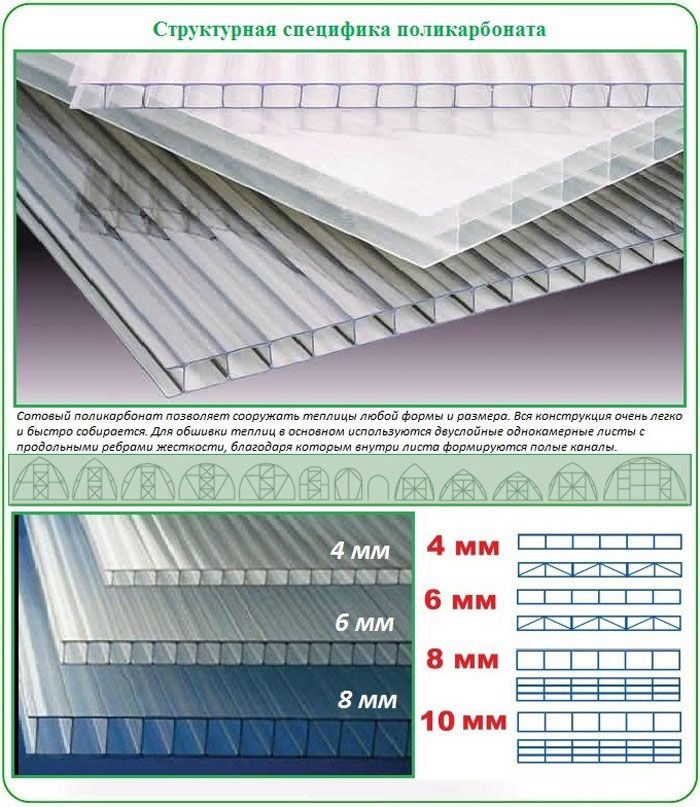

- cellular (honeycomb) Is a panel consisting of two or three layers of material, between which longitudinal stiffeners are placed.

Important! Monolithic polycarbonate is not used in the manufacture of greenhouses due to its high cost.

The presence of an air gap in the construction of cellular-type products ensures low thermal conductivity of the material, which is exactly what is needed when operating greenhouses.

Note! To reduce the cost of cellular polycarbonate, manufacturers produce lightweight modifications, in which the thickness of the outer layer and partitions is less than in the standard version. This negatively affects the physical properties of the material (strength and thermal conductivity).

The use of cellular polycarbonate in construction greenhouses, in contrast to monolithic analogs, is associated with such properties:

- relatively low cost;

- the best thermal performance;

- light weight and sufficient strength;

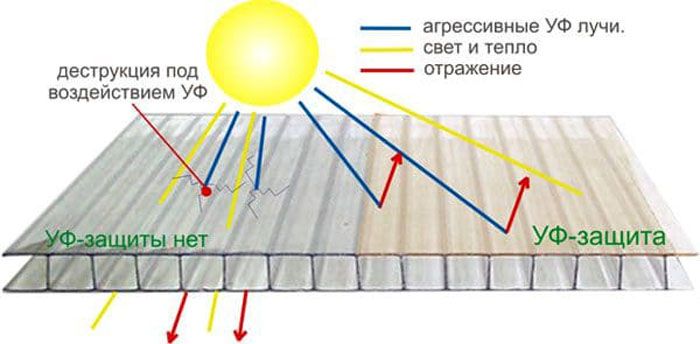

- the presence of a protective layer against exposure to ultraviolet rays.

The main disadvantage of cellular models is their susceptibility to slight deformation when the ambient temperature changes, which must be taken into account when installing and using them.

Depending on the thickness of cellular polycarbonate, the shape of its cells also changes, which affects its strength and possibilities of use.

Related article:

DIY polycarbonate greenhouse. Drawings, types of structures, step-by-step construction, advice and recommendations of specialists and much more in a separate publication of our portal.

How to choose polycarbonate for a greenhouse

When choosing a material, it is necessary to take into account the indicators that determine the further successful operation of the greenhouse:

- the density and shape of the cells - determine the service life and depend on the quality of the raw materials used, as well as the manufacturing technology;

- geometric dimensions - determine the thermal characteristics of the material, its flexibility and the possibility of covering a certain area of the coating without the presence of joints;

- the presence of a protective film against exposure to ultraviolet rays;

- service life - depends on the quality of the raw materials used and the manufacturer's brand;

- during visual inspection on the surface of the material there should be no noticeable bubbles and foreign inclusions, the sheets should be transparent, smooth and even.

Important! With an increase in the thickness of cellular polycarbonate, its strength and thermal insulation characteristics increase, but this negatively affects its light transmittance.

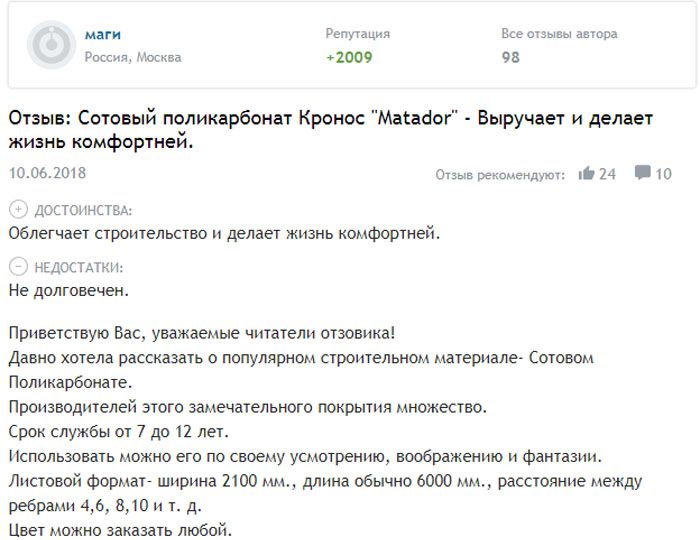

The standard dimensions for the material in question are 2100 × 6000 mm and 2100 × 12000 at a thickness of 4/6/8/10/16 mm. For lightweight modifications, the thickness can be 3.0 or 3.5 mm, and for the construction of critical structures - 20 and 32 mm.

Important! Lightweight modifications have the designation "Light" in their marking, or the thickness of the sheet is not reflected at all, which indicates this type of product.

The service life of polycarbonate depends on the quality of the raw materials used and the technology of its manufacture.

Products of European brands are guaranteed to be used for 15-20 years, Chinese modifications can be operated for 5-7 years, and domestic manufacturers, as a rule, guarantee up to 10 years of successful use of their products.

Note! When constructing greenhouses, as a rule, sheets with a thickness of 4.0-8.0 mm are used.

The following video will tell you how to choose polycarbonate when building a greenhouse:

An extensive selection of offers allows you to select the desired material for technical and physical characteristics in a given price range

Related article:

Greenhouses and greenhouses made of polycarbonate: sizes, prices, advantages, disadvantages, the choice of a suitable place on the land and the correct wording of the search criteria; materials suitable for creating a load-bearing frame and sheathing; an overview of current market offers, finished products of specialized manufacturers - read the publication.

Leading polycarbonate manufacturers

Polycarbonate from European, Russian and Chinese manufacturing companies is represented on the Russian building materials market. The most popular brands in different price categories are:

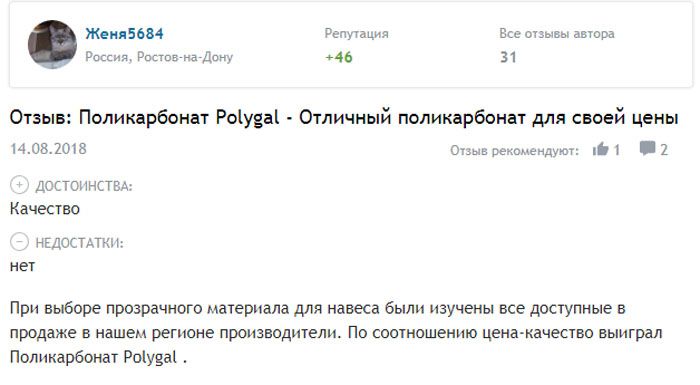

- Polygal (Israel);

- "Makrolon" (Germany)

- Brett Martin (UK);

- Polyu Italiana (Italy);

- "Kronos", "Safplast", "Karboglass", "ROYALPLAST", "Sellex" and "Karat" (Russia);

- Julite, Hai Gao and Goodlife (China).

In addition to the above brands, there are products from other manufacturers on the domestic market, depending on the region and the presence of official dealers of certain companies.

Recommendations for choosing a polycarbonate greenhouse

Various types are currently on sale. ready-made greenhousesequipped with polycarbonate cover. Models can differ in geometric dimensions and shape, materials used in the manufacture of the frame, and types of polycarbonate.

When choosing a greenhouse model, you need to pay attention to the following indicators:

- Frame material and structure - determine the weight and strength of the product.

- Size and shape - depends on the need for the vegetables grown and the personal preferences of the user.

- The type of polycarbonate used - determines the life of the greenhouse and its thermal characteristics.

- The type and presence of fasteners on the frame - determine the method of installation on a foundation or other type of foundation.

- The presence of the possibility of interfacing with similar structures - allows you to increase the usable area if necessary.

- The possibility of installing an automation system (opening the vents) - facilitates the use of the product, especially when located remotely.

- Cost - depends on the manufacturer's brand and the quality of the materials used.

The model with a sliding roof allows you to optimize the creation of a microclimate in the inner space of the greenhouse

Review of prices and user reviews of popular brands of polycarbonate

You can buy polycarbonate for a greenhouse in any region of our country, and its cost will depend on the place of purchase and the brand of manufacturers.

Let's imagine the prices for some types of polycarbonate.

Transparent polycarbonate thickness 4 mm:

Transparent polycarbonate 6 mm thick:

Transparent polycarbonate 8 mm thick:

Lightweight 3mm clear polycarbonate:

4mm colored polycarbonate:

Users in the Network share about the successful use of polycarbonate as a covering for a greenhouse.

Here are some of the reviews:

Feedback on the brand "Polyu Italiana":

Video: how to choose a greenhouse - professional recommendations.

With a variety of proposals, it is sometimes difficult to make the right choice on your own. This applies to any product, including greenhouses, made using polycarbonate.

The following video can be useful in solving this problem, especially for novice summer residents and owners of suburban real estate: