Choosing the best greenhouse or polycarbonate greenhouse: detailed tables with sizes and prices

Summer time does not always make us happy with fine days. Cold, protracted periods, alas, are not uncommon for many Russian latitudes. That is why every summer resident necessarily organizes a greenhouse or greenhouse on his site. Modern materials allow you to choose a strong and durable structure. In this review, we will talk about how to choose greenhouses and greenhouses made of polycarbonate, study the sizes and prices, as well as the features of their operation. This information will help to implement a project of any level of complexity without errors and unnecessary costs.

With the help of such structures, seedlings are grown, increase yields, and successfully solve other practical problems.

The content of the article

- 1 Greenhouses and greenhouses made of polycarbonate: advantages and disadvantages

- 2 What are polycarbonate greenhouses and greenhouses

- 3 How to choose a polycarbonate greenhouse taking into account important criteria

- 4 Leading manufacturers of ready-made polycarbonate greenhouses

- 5 How much does a polycarbonate greenhouse cost - market overview with prices

- 6 Additional useful information

Greenhouses and greenhouses made of polycarbonate: advantages and disadvantages

With the help of greenhouses and polycarbonate greenhouses, it is very convenient to prepare seedlings not only in spring, but even in winter. The cover is very durable and can withstand snow. With sufficient sun, the temperature inside such a greenhouse can reach 25-30 ° C, even in frosty conditions. There are models that, even with additional heating, will make it possible to ventilate the seedlings, for this special vents are provided. In greenhouses, moisture loss is noticeably reduced due to the absence of wind. Therefore, you will need to water the plants less often.

This alone is enough to think about installing a polycarbonate greenhouse (greenhouse) on your own land. Separately, it should be noted a significant increase in yield indicators. Depending on the applied technology, the characteristics of the agricultural crop, an increase of up to 150-250% can be obtained. In addition, a robust structure will protect your crops from pests. However, for objectivity, it is necessary to note the negative points that are quite subjective:

- Excessive price, which does not correspond to real consumer characteristics.

- Damage that occurs with the wrong choice of materials for the load-bearing frame, sheathing.

- Reduced service life due to improper installation and operation.

Before you decide to buy a greenhouse, pay attention to the key points:

- installation site;

- basic materials;

- shape and size;

- assembly features.

All these features can affect your decision and the cost of the finished greenhouse.

What are polycarbonate greenhouses and greenhouses

First of all, it is important to decide whether the greenhouse will be all-season or not. After all, if the summer maintenance of seedlings for cucumbers does not require special care, then a flower garden for fresh flowers must be connected to heating. Provide optimal humidity and additional lighting. To find out what kind of polycarbonate greenhouses there are, photos and prices of finished factory products are not enough. Let's consider the main points in more detail.

Stationary and demountable structures

The steel parts of the frame are welded together. These operations are performed in a production environment. Subject to the norms of technological processes, a reliable durable seam is obtained. It is cleaned, a protective anti-corrosion layer is created from a primer and paint.

The experience gained will be useful in practice. Welding equipment is used to erect fences, repair equipment, create unique products. However, all of the above is associated with a significant investment of time and money. It is much easier to purchase an assembly kit.

Such greenhouses and polycarbonate greenhouses are easy to transport. It is quite enough to rent a trailer or install a trunk on the roof of a car. If necessary, correct installation can be done alone. Separately, it should be emphasized the advantages of simple replacement of failed parts for quick and inexpensive repairs.

Related article:

Do-it-yourself greenhouse from a profile pipe. In a separate review, detailed instructions for the design and construction of a structure from a shaped pipe are provided with photo examples.

Different shapes of polycarbonate greenhouses with photos inside and outside

The examples below are not dogmatic. If necessary, some structures are connected to form large objects. On an individual order or on their own, they create structures with unique dimensions. In any of the options, the general technical requirements for the objects of the corresponding category are taken into account.

Arched structures

Such greenhouses and polycarbonate greenhouses are one of the most common solutions. Arcuate supports are created without welds to increase strength. The bending radius is selected taking into account the permissible deformation of the polymer sheets. The walls are made with a minimum slope to facilitate movement and cultivation of the land throughout the area.

Polygonal greenhouses and polycarbonate greenhouses

An arch-like shape can be created from several straight pieces. This solution allows the use of standard pipes and profiles. There is no need to bend the polycarbonate, so the sheet is easier to attach.Breaking the integrity of the skin is prevented. It is easier to ensure the tightness of the structure.

These photos show the variety of types of polycarbonate greenhouses. Disadvantages of these forms:

- the complexity of the assembly;

- decrease in strength, compared with the previous arched version;

- weight gain;

- the need to seal numerous joints.

Related article:

Do-it-yourself greenhouse made of plastic pipes. A separate review provides a detailed overview of the use, design and installation of PVC pipe greenhouses.

Teardrop shapes

These constructs fix some of the reported issues:

- There is enough space near the walls for users to move in a comfortable position, to accommodate tall plants.

- The pointed upper part of the roof prevents snow accumulation, which simplifies the maintenance of the structure in the winter.

- The number of joints is less than in polygonal greenhouses and polycarbonate greenhouses.

Single-slope polycarbonate wall structures

Such structures are chosen if it is supposed to be supported on a capital building. In this case, the resistance to wind and other loads is significantly increased. The simplicity of the components of the design implies an affordable cost price.

It is easy to bring water, lighting, heating from home to a similar greenhouse and polycarbonate greenhouse

The single-slope structure can be mounted separately on the site. This option simplifies the correct orientation, taking into account the cardinal points.

The curved roof corner is applied to create a special look. It only slightly improves light transmission, but increases the complexity and cost of the structure.

Related article:

DIY polycarbonate greenhouse. Drawings, types of structures, step-by-step construction, advice and recommendations of specialists and much more in a separate publication of our portal.

Gable greenhouses and polycarbonate greenhouses

The classic "house" is used quite often. This famous design has been worked out to the smallest detail. Assembly does not cause significant difficulties. A large wall height will come in handy. The internal volume is used rationally. Shelves for small pots with seedlings can be fixed on the vertical parts of the frame.

Related article:

DIY greenhouse made of scrap materials. Structural features, the use of various materials to create a reliable load-bearing frame and high-quality cladding, step-by-step installation instructions with the rules for choosing a suitable place on the land are in our publication.

Polycarbonate greenhouse with opening roof, design features for different seasons

One of the prerequisites for proper plant care is comfortable, adjustable ventilation. The following examples with a photo show how this task is solved in different types of polycarbonate greenhouses.

- Sliding straight segments of a gable roof

- Butterfly design

- Similar greenhouses "Shells" made of polycarbonate are used for growing seedlings

- Here, holes in the walls and roof are used for effective ventilation.

- To move roof parts at high heights, special mechanisms with a manual or electromechanical drive are used.

- Rollers with bearings provide secure support, quiet, unobstructed movement

For year-round operation, heat from the sun and good sealing of the joints are not enough. The easiest way is if the building is located next to a residential building. In this case, the costs of installing engineering networks are reduced.

Related article:

Greenhouse Butterfly. The device, design and operation features, comparison with the Breadbasket, diagrams and recommendations for building with your own hands, reviews of summer residents on the practice of using a greenhouse are in our publication.

How to choose a polycarbonate greenhouse taking into account important criteria

The load-bearing components must withstand not only the weight, but also the hurricane wind without damage. Increased strength is achieved thanks to sturdy casing. A solid foundation is essential for good stability. The parameters of the base are evaluated taking into account the characteristics of the soil. These comments confirm the need for an integrated approach when assessing individual project parameters.

The choice of materials for the frame of the greenhouse made of polycarbonate

In order to facilitate these parts, they are made from a galvanized metal profile. Such products (wall thickness less than 0.8 mm) have a low margin of safety. Care should be taken when transporting, unloading. Excessive force when tightening bolts and nuts can damage the mount.

Steel pipes (squares) are much stronger. It is recommended to choose products with cross-sectional dimensions over 20 × 20 mm. With a wall thickness of more than 1.25 mm, a strong frame will be obtained. In any case, the pitch between horizontal and vertical supports depends on the parameters of the polycarbonate. With a sheet thickness of 4-5 mm, the distance is set no more than 40-50 cm.

Corrections are made taking into account the real thickness of the snow cover, wind loads in the region

Note! A slope of 30-35 ° is sufficient to prevent the accumulation of precipitation on the roof.

Technical characteristics of different types of polycarbonate sheets

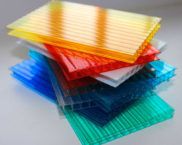

This material is well suited for covering greenhouses and greenhouses. Polycarbonate transmits sunlight, has a fairly high strength. Flexibility comes in handy for creating arches and other curved surfaces. Such products do not absorb water, they are quickly cleaned of dirt. They are harder to damage than plastic sheeting (glass).

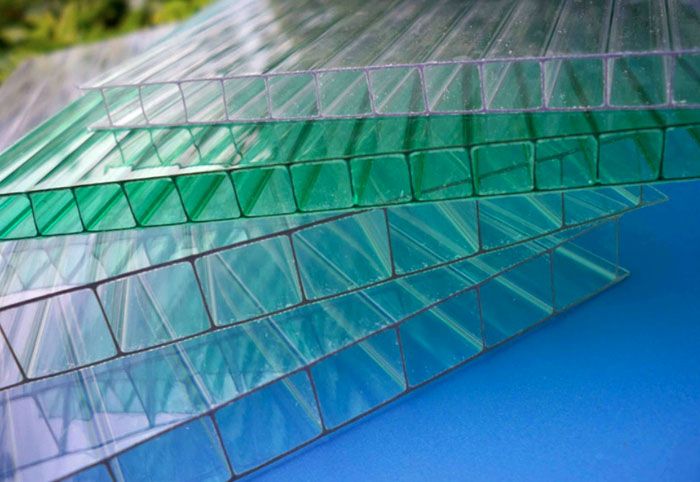

For cladding greenhouses and greenhouses, polycarbonate sheets with cavities and stiffening ribs are used

| Sheet thickness, mm | Specific gravity, kg per m2 | Thermal conductivity, W per m2 × ° C | Permissible radius at the bend point, cm |

|---|---|---|---|

| 4 | 0,8 | 3,6 | 80 |

| 6 | 1,3 | 3,4 | 130 |

| 8 | 1,5 | 3 | 150 |

| 10 | 1,7 | 2,7 | 170 |

| 16 | 2,5 | 2 | 250 |

Note! High-quality polycarbonate honeycomb panels for greenhouses and greenhouses retain good consumer parameters for 8-15 years.

Estimating the size of a polycarbonate greenhouse

The dimensions of this building are subject to actual family / business needs. You should also consider:

- plant sizes;

- distance between beds;

- features of watering;

- application of hydroponics, volumetric growing technologies.

Leading manufacturers of ready-made polycarbonate greenhouses

The Agroprofil company located near Moscow is well known to domestic consumers. The company has been engaged in specialized activities for over 10 years. The accumulated experience helps to offer products that meet real needs. The manufacturer offers 10-year official warranty, which indirectly confirms the use of high-quality materials and components.

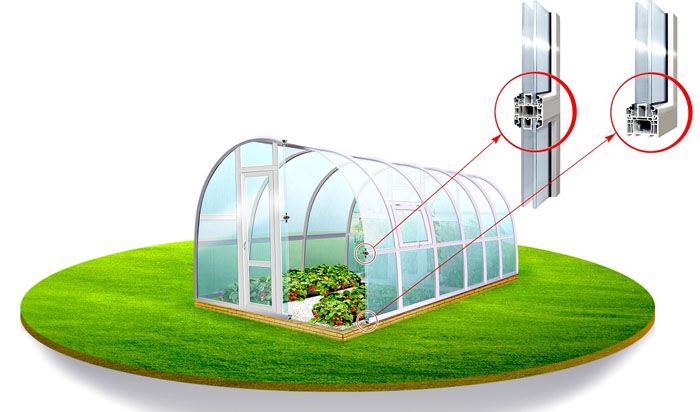

Greenhouses and greenhouses "Agroprofil" made of polycarbonate, created using "window" profiles, are well adapted to the conditions of year-round operation

The specialized company "Rus-Teplitsa" underlines its main line of business with its name. The assortment includes models with frames made of galvanized profiles and steel pipes. A choice of sheathing with different polycarbonate sheets. Own production allows you to fully control the manufacturing process.

At a suitable distance from the warehouse, Rus-Teplitsa provides the services of a professional assembly team

The Baller plant offers a smaller assortment than the brands mentioned above. However, this manufacturer has been producing products for over 14 years. Solid experience has helped to improve the basic performance of greenhouses and polycarbonate greenhouses.

Cooperation with specialized enterprises for the production of high-quality polymer honeycomb panels helped to reduce overhead costs

How much does a polycarbonate greenhouse cost - market overview with prices

Additional useful information

Thematic photos and videos explain the installation process of a collapsible polycarbonate greenhouse. Reasonable prices of manufactured products allow you not to think about the independent production of analogs. But if you wish, it is not too difficult to assemble a greenhouse with your own hands.

Remember that investing in a reliable product will pay off many times over in the future. Leave useful tips in the comments. Ask questions to get expert advice from the editors of the online magazine homemaster.techinfolux.com/en/. Polycarbonate greenhouse assembly video: