Cozy house for cucumbers, Or how to build a polycarbonate greenhouse with an opening top for vegetables

A greenhouse or a greenhouse in the country - a stable harvest in the summer season and a guarantee of full pantries with pickles all autumn and winter. To get a decent harvest, gardeners use universal polycarbonate greenhouses with an opening top. How to choose the best design from the many offers on the market, we will tell you today in this article by the homemaster.techinfolux.com/en/ editorial office. Our recommendations will be useful for the correct placement of the greenhouse structure and its subsequent operation.

The content of the article

- 1 Why do we need open-top polycarbonate greenhouses: basic definitions, advantages and disadvantages

- 2 Construction components, different types of greenhouses and convertible greenhouses

- 3 Choosing a location for a greenhouse with a convertible top

- 4 How to make a reliable base for a greenhouse with an opening top

- 5 High-quality build features

- 6 Purchase of a polycarbonate greenhouse with an opening top: prices, parameters of popular models

- 7 Additional information, conclusions

- 8 Video of the assembly of a polycarbonate greenhouse with an opening top

Why do we need open top polycarbonate greenhouses: basic definitions, advantages and disadvantages

These specific structures are used to reproduce the beloved idea of all summer residents - technologies of "closed ground". The selected part of the site is covered with a structure with transparent walls and a roof. It lets in sunlight, but prevents heat loss. In this case, the plants are sheltered from the wind and protected from rain and hail. An additional advantage of the open-top polycarbonate greenhouse is the rational use of water. Evaporation in this case is less compared to open beds.

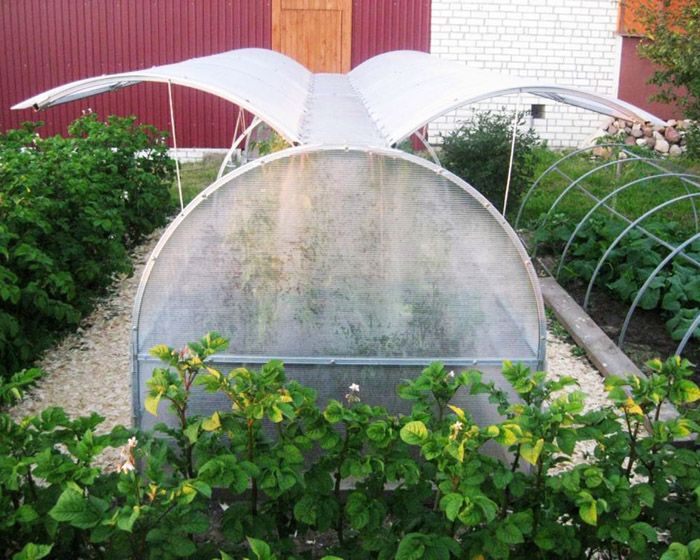

The picture shows the following details of a polycarbonate greenhouse with an opening top:

- The load-bearing frame (1) provides the required rigidity.

- Cellular polycarbonate (2) does not block the passage of sunlight.

- The cover is held in the raised position using the lock (3).

- In this model, shelves (4) are made at the bottom for storing garden tools.

It is necessary to give the differences between two typical structures: greenhouses and greenhouses.This will simplify the correct comparison of pros and cons, areas of application. The information below will prevent mistakes when choosing the right products in the store. A greenhouse is a protective structure up to 120-150 cm high. If necessary, in addition to solar heating, biological heating (humus, manure) is used. There are no doors. The workspace is accessed from the top. This design is suitable for seasonal work with seedlings, low-growing plants.

The height of these structures is sufficient for moving inside at full height. For year-round operation, additional heating is used with heat supplied from the main home system. The load-bearing frame is calculated taking into account snow loads.

Construction components, different types of greenhouses and convertible greenhouses

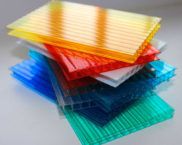

The material chosen for cladding, in terms of the amount of consumer parameters, surpasses the alternative options:

- It is stronger than plastic sheeting, which has to be changed every spring.

- It cannot be easily shattered, like glass, by a careless or deliberate action.

- The honeycomb structure forms an additional load-bearing frame; therefore, an increase in the distance between the supporting elements is permissible.

- Voids in the structure of the sheet significantly improve the thermal insulation parameters.

Greenhouses and greenhouses made of polycarbonate with an opening top perform their functions without major repairs for 10-15 years or more. This compensates for the relatively high cost of the cladding material.

Note! It is recommended to purchase transparent sheets from 4 mm thick. On one side, a protective layer is factory-made. It prevents UV damage to the polymer.

The load-bearing frame, as a rule, is created from metal pipes rectangular in cross-section. Anti-corrosion parameters are improved by galvanizing, powder paints. The wall thickness of the products must be at least 1 mm in greenhouses to ensure resistance to heavy loads. To create lightweight polycarbonate greenhouses with an opening top, a tin profile is used. Greenhouses and greenhouses that open from above are equipped with different ventilation systems. Below are the most common engineering solutions.

These greenhouses are often called "Belgian" by country of origin. The walls can be enlarged, equipped with doors for easy access. Simplicity is the main design advantage. It is not difficult to build an analogue with your own hands from the simplest blanks. If wood is chosen for the manufacture of the frame, do not forget to impregnate it with a special composition from decay.

Here, the wall and cover form a single segment. It is lifted using a special handrail handle. Moreover, the desired angle is fixed with the help of supports.

If you want to convert the greenhouse into a greenhouse, raise the height of the side walls. The sloping shape of the roof of the open-top polycarbonate greenhouse does not trap snow. The minimum number of jumpers ensures good light transmission. In such structures, it is easy to make sealed seams for better thermal insulation.

Note! When creating an open-top polycarbonate greenhouse on your own, the permissible bending radius of the sheet should be taken into account. These data are given in the accompanying technical documentation.

Related article:

Greenhouse Butterfly. The device, design and operation features, comparison with the Breadbasket, diagrams and recommendations for building with your own hands, reviews of summer residents on the practice of using a greenhouse are in our publication.

Choosing a location for a greenhouse with a convertible top

In any case, a lot of sunlight is needed for active growth and good heating. Therefore, a place at a sufficient distance from the fence, gazebos, large bushes and shady trees is suitable.Also consider the following guidelines:

- Increase the distance to cesspools and septic tanks up to 25 m.

- Maintain a distance of 10 m or more from the well, taking into account the direction of the flow of groundwater.

- Check the orientation of the open-top polycarbonate greenhouse relative to the cardinal points.

- In low-lying areas and with high groundwater levels, install a protective drainage system along the loop.

Consider plant care techniques. If necessary, make a supply of electricity, water supply. Do not forget about the insulation of engineering networks in the winter.

In this type of accommodation, not only the proximity of housing is useful. Support on a solid wall significantly strengthens the structure

Related article:

DIY greenhouse made of scrap materials. Structural features, the use of various materials to create a reliable load-bearing frame and high-quality cladding, step-by-step installation instructions with the rules for choosing a suitable place on the land are in our publication.

How to make a reliable base for a greenhouse with an opening top

The first example shows a compact open-top polycarbonate greenhouse. It does not create significant ground loads. At the end of the season, like ordinary garden furniture, it is removed indoors.

For larger products, a foundation is required. A conventional strip base can be created from a cement-sand mortar. Reinforcement is performed using reinforcement. On soft soils, screw piles are used.

Open-top polycarbonate greenhouses are lightweight. It is quite acceptable to use a wooden frame as a base. They dig a trench along the contour, fill up the sand, ram the bottom. Pour a mixture of cement and gravel, level the surface.

They also install light greenhouses directly on the ground. Hollow arches are mounted on steel pins, which are driven into the ground to a depth of 40-60 cm. In any of the options, it is necessary to control the horizontal position of the installation with a building level. Distortions can impair the functionality of the leaf opening mechanisms.

Related article:

Do-it-yourself greenhouse from a profile pipe. In a separate review, detailed instructions for the design and construction of a structure from a profile pipe are provided with photo examples.

High-quality build features

Factory open-top polycarbonate greenhouses are supplied in sets. The complete set contains all the necessary components:

- support frame made of metal profile;

- arcs and cross members;

- handles, clamps, hinges;

- fasteners;

- cladding material in sheets.

Long guides, walls and lid are assembled according to the manufacturer's instructions. Plastic plugs are inserted into the ends. Using an electric or manual jigsaw, cut cellular polycarbonate with preliminary marking. Installation on the foundation is carried out from the bottom up. In large greenhouses, joints are sealed, door leaves are installed. At the final stage, the operability of the opening mechanism is checked.

Note! The stabilizing protective layer is covered with foil during transportation. It can be distinguished by its characteristic blue tint.

Such structures are easy to transport and assemble. If you wish, you can quickly dismantle the structure, move it to another place, or sell it. It is not too difficult to replace a damaged element, to increase the length of the greenhouse.

Purchase of a polycarbonate greenhouse with an opening top: prices, parameters of popular models

In order to buy polycarbonate greenhouses with an opening top without errors, it is necessary to clarify the composition of the set, warranty obligations. Check the opinions of users. For objectivity, examine the positive and negative ratings.

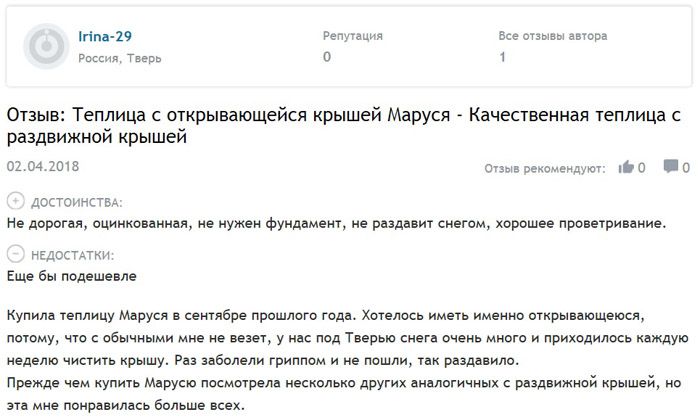

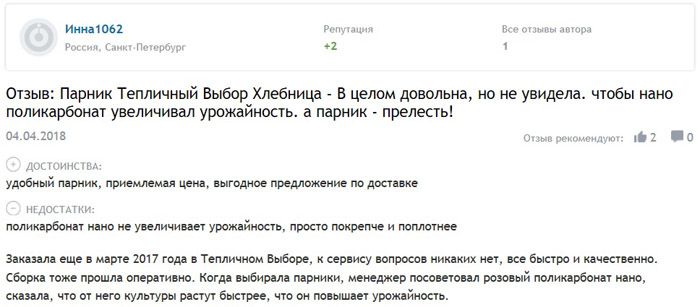

Feedback on the Khlebnitsa model (Greenhouse choice):

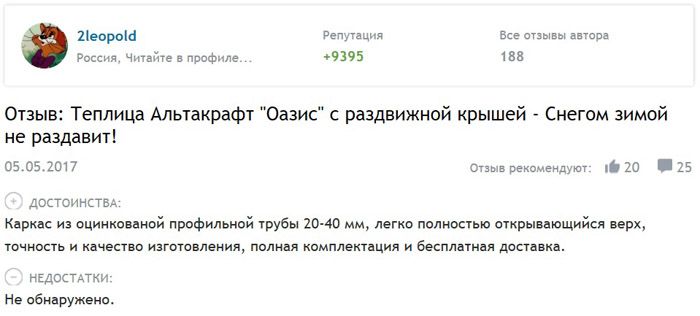

Feedback on the model "Oasis" (Altacraft):

If you buy a polycarbonate greenhouse with an opening top with a professional assembly, you can get a comprehensive warranty for the product and installation work

Related article:

DIY polycarbonate greenhouse. Drawings, types of structures, step-by-step construction, advice and recommendations of specialists and much more in a separate publication of our portal.

Additional information, conclusions

The reasonable cost of manufactured products leaves almost no chance for individual creativity. However, a homemade product can be created with unique dimensions in exact accordance with the characteristics of the plants and the site. With year-round operation, the project is complicated by the installation of lighting, heating, and water supply.

For regular cleaning, use suitable, non-abrasive products. Detergents and devices are used that do not damage the protective coating of the metal frame and polymer sheathing. Use the comments for more information. Post your own ideas, comments on manufactured items, homemade designs.