Fiberglass reinforcement - how to choose and where to use

The emergence of new technologies in various industries has not spared the construction industry either. New materials have appeared that have made it possible to reduce the time required for construction and installation work and reduce the weight of assembled structures, improve the thermal characteristics of the facilities under construction and their operational characteristics. One of such materials, which has appeared on the construction market of our country in recent years, is fiberglass reinforcement, which will be discussed in this article by the homemaster.techinfolux.com/en/ editorial office.

The content of the article

- 1 Structure, standard sizes and performance characteristics of composite fiberglass reinforcement

- 2 Fields of application and varieties of fiberglass reinforcement

- 3 Production and requirements for fiberglass reinforcement

- 4 Pros and cons of fiberglass composite rebar

- 5 What to look for when choosing

- 6 Which reinforcement is better: metal or fiberglass

- 7 Leading manufacturers

- 8 Review of prices and user reviews of composite fiberglass rebar

- 9 Video: feedback on the use when pouring the foundation

Structure, standard sizes and performance characteristics of composite fiberglass reinforcement

A building material made of fiberglass fibers impregnated with a polymer binder, formed in the form of rods with ribs of a given size and hardened during the production process is called fiberglass reinforcement (SPA or ASP).

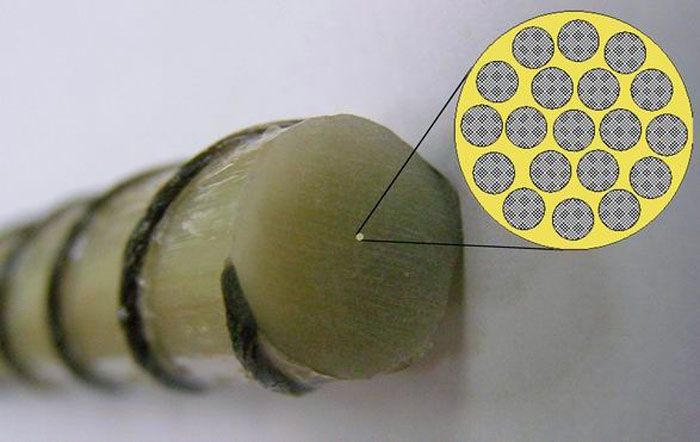

By its structure, the SPA is a bar consisting of two parts, such as:

- inner core - provides the strength characteristics of the product and is made of fiberglass fibers, placed parallel to each other or in the form of a pigtail, filled with polymer resin;

- outer layer - made of composite fibers wound onto an inner core or in the form of a fine fraction of abrasive applied by spraying.

In addition to the fact that the SPA differs in the type of outer layer, it is classified according to standard sizes accordingly:

- in diameter - from 4.0 to 18.0 mm;

- in length - up to 12 m (when realized in the form of rods).

Note! Fiberglass reinforcement with a diameter of up to 10.0 mm inclusive can be realized in the form of a rod or in coils. In the case of implementation in the form of a coil, its length depends on the equipment on which it is manufactured. Reinforcement with a diameter of more than 10.0 mm is sold only in the form of rods.

The main performance characteristics for this material are the following:

- Diameter - defines the ultimate bending and tensile strength of the product.

- Weight - characterized by the mass of one running meter of the product.

- Coiling step - for SPA with embossed coverage.

Fields of application and varieties of fiberglass reinforcement

Currently, SPA is sold not only in the form of rods and in coils, but is also offered in the form of reinforcing nets and reinforcing cages of various shapes and dimensions.

Due to the variety of offers and successful experience of use, this material is used for various construction and installation works, as well as for the manufacture of various structures.

The main areas of use of fiberglass reinforcement are:

- reinforcement of concrete structures (wells, walls, etc.) and foundations;

- strengthening of masonry made of bricks and blocks of various types;

- when building roads and other types of surfaces;

- to strengthen embankments and other types of foundations.

Note! SPA has found its application in summer cottages: it is successfully used in the manufacture of greenhouses and greenhouses as arches on which covering material is laid, and also as fences and supporting structures for fruit and vegetable crops.

Production and requirements for fiberglass reinforcement

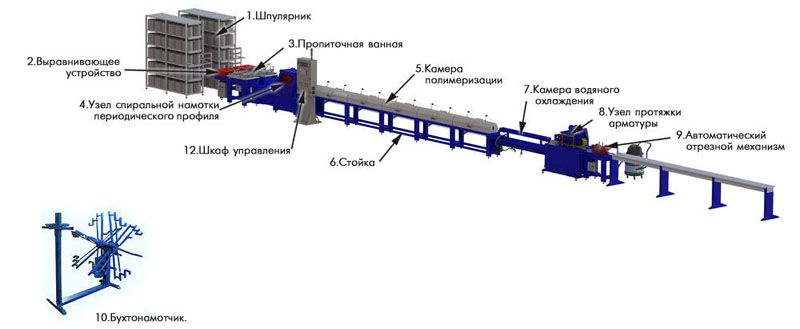

SPA production is a rather complex technological process that requires special equipment and raw materials.The raw material used is aluminoborosilicate glass and an oil-containing polymer binder.

All the main elements of the SPA production line are shown in the following figure:

Pros and cons of fiberglass composite rebar

The reason that after the appearance on the market, the spa became quite in demand, was the positive qualities of this material, which include:

- light weight;

- resistance to oxidation and other types of corrosion;

- low thermal conductivity;

- long service life;

- is a dielectric (does not conduct electric current);

- possibility of application without using welding equipment.

There are also disadvantages, but there are much fewer of them, these are:

- relatively low thermal stability;

- low indicators of elasticity.

Related article:

Tying reinforcement for strip foundation is a reliable way to create a rigid metal frame for reinforced concrete structures. We will tell you how to correctly and inexpensively perform these works in this detailed material.

What to look for when choosing

When the choice fell on the use of fiberglass reinforcement when performing construction and installation work, then when buying it, you should pay attention to such indicators as:

- Diameter - must correspond to the declared values.

- The color of the reinforcement should be uniform and with shades not darker than the declared characteristics.

- The quality of the winding of the outer layer.

- Products must have appropriate quality certificates and a test report.

Important! The presence of the SPA color in darker shades than those stated by the manufacturer indicates that the temperature regime of production was violated during the production process. The armature of this color is burnt and its technical characteristics cannot correspond to the declared ones.

The flexibility of the SPA allows it to be used in the construction of structures of complex geometric shapes without cutting

When choosing a spa, it is best to initially find out the reputation of the company that produces this material, for which you should read reviews on the Internet and in other sources of information.

Related article:

DIY strip foundation: step by step instructions. In the article, we will consider the pros and cons of this foundation, the nuances of its correct pouring, as well as what brand of concrete is best to choose in order to get a high-quality structure.

Which reinforcement is better: metal or fiberglass

Which reinforcement to choose - metal or fiberglass - is decided at the stage of development of project documentation, or individually, based on a comparison of the main technical characteristics given in the following table:

| Characteristic | Metal | Fiberglass |

|---|---|---|

| Ultimate strength, MPa | 390 | 1300 |

| Thermal conductivity coefficient, W / m2 × K | 46 | 0,35 |

| Density, kg / m³ | 7850 | 1900 |

| Elasticity | + | + |

| Plastic | + | - |

| Corrosion resistant | - | + |

| Dielectric properties | - | + |

Leading manufacturers

The production of composite fiberglass reinforcement is carried out in many regions of our country. This is especially true for areas with developed industrial infrastructure, such as:

- Moscow and the Moscow Region - "Moscow Plant of Composite Materials", LLC "SPEC" SPETSPOLIMER ", LLC NPK" ARMASTEK "and others;

- St. Petersburg and the Leningrad Region - Leader-Composite and others;

- Yaroslavl - "Yaroslavl Composite Plant";

- Yekaterinburg and the Sverdlovsk Region - Uralteplostroy, UZKT LLC, Elpromtech LLC, NPF UralSpetsArmatura LLC;

- Saratov - LLC "Povolzhskaya armature" (Polarm).

Note! In many cities, small businesses operating at the local level are engaged in the production of SPA, so if you need to find such a production in your region, you need to study the building materials market.

A wide range of SPA allows you to choose not only by technical characteristics, but also by the form of implementation

Review of prices and user reviews of composite fiberglass rebar

The cost of a spa depends on its technical characteristics, place of purchase and the company selling it.

As of the III quarter of 2018, the average cost of fiberglass reinforcement, when sold through dealers of manufacturing companies, is:

| Manufacturer | Brand | Diameter, mm | Outer layer type | Cost (as of September, rubles / p.m. |

|---|---|---|---|---|

| PC "Composite" | ASK | 8,0 | coiled | 11,9 |

| 10,0 | 17,9 | |||

| 12,0 | 26,9 | |||

| ASP | 8,0 | sandy | 13,9 | |

| 10,0 | 23,9 | |||

| 12,0 | 38,9 |

| Manufacturer | Brand | Diameter, mm | Outer layer type | Cost (as of September, rubles / p.m. |

|---|---|---|---|---|

| "ArmatSoyuz" | SPA | 4,0 | coiled | 6,9 |

| 6,0 | 7,9 | |||

| 8,0 | 11,5 | |||

| 10,0 | 17,5 | |||

| 12,0 | 26,9 | |||

| 14,0 | 42,9 | |||

| 16,0 | 60,9 | |||

| 18,0 | 94,9 |

| Manufacturer | Brand | Diameter, mm | Outer layer type | Cost (as of September, rubles / p.m. |

|---|---|---|---|---|

| "Armplast" | ASK | 4,0 | coiled | 5,5 |

| 6,0 | 7,9 | |||

| 8,0 | 11,5 | |||

| 10,0 | 17,9 | |||

| 12,0 | 26,9 | |||

| 14,0 | 42,74 | |||

| 16,0 | 60,52 | |||

| 18,0 | 94,32 | |||

| 20,0 | 117,6 | |||

| 22,0 | 138,99 | |||

| 25,0 | 180,17 | |||

| 28,0 | 223,10 | |||

| 32,0 | 292,74 | |||

| 36,0 | 312,80 |

Individual developers and professional builders leave their feedback on the facts of using the spa.Here is some of them:

Video: feedback on the use when pouring the foundation

Feedback on pouring the slab foundation:

Reviews of experts:

Feedback on the use when pouring the strip foundation: