A beehive with your own hands: how to make a quality "home" for bees without mistakes

If you are an avid beekeeper or are going to become one, then you should definitely make a beehive with your own hands. This can save you significant money. This process will help you become familiar with the behavior of bees and effective honey production technologies. Self-production will improve the consumer characteristics of honey, extend the life of the hive. We will talk about all the nuances of creating a house for bees in today's review.

The content of the article

- 1 Beekeeping for beginners: where to start, basic principles

- 2 Bee hive device: typical design, features of popular modifications

- 2.1 The Dadan-Blatt hive: simplicity and efficiency

- 2.2 Langstroth-Ruth hive: how to keep many bees without unnecessary difficulties

- 2.3 Horned hive: minimum cost and easy manufacturing

- 2.4 Alpine hive: space saving

- 2.5 Cassette hive: solving large-scale tasks

- 2.6 Beehive lounger: comfortable conditions for several bee colonies

- 2.7 Beehive boa: description and important details

- 3 How to make a beehive with your own hands: detailed instructions from "A" to "Z"

- 4 Conclusions and additional recommendations

Beekeeping for beginners: where to start, basic principles

A detailed study of the vital activity of bees will help create comfortable conditions for them. Below is the basic knowledge that will make it easier to understand the requirements for the main and additional structural elements of the hive.

Even a superficial knowledge of the families of these insects allows one to be convinced of the clear organization of the communities. Worker bees have a functional division, which is largely due to a certain age range.

After leaving the cell, the lack of strength limits the possibilities of the insects. They are looked after and fed by adults. But after 1-2 days, young bees begin their first duties. They create impeccable sanitary and hygienic conditions in the cell so that the uterus can lay eggs there.

Further (as they grow older) bees perform the following functions:

- feeding the larvae;

- honeycomb construction, clogging of filled cells, renovation work;

- security;

- taking nectar;

- removing excess moisture from it and other processing procedures;

- collection of pollen, nectar, and other useful and essential substances for the maintenance of vital activity.

Honey bees have well-developed senses. To search for flowers and in other situations, they use sight, smell, touch, hearing, taste buds.

They mate with drones outside the hive, laying eggs up to several thousand per day under favorable conditions. During this period, they need high-quality nutrition with a sufficiently large energy supply per unit volume.

Of particular importance is the temperature regime in the beehive. The full development of the pupa, the purpose of the adult insect, depends on it. Some bees have the ability to raise their own temperature above + 40 ° C, acting as biological "heating elements".

Here are just some information about the life of bees. But even this information is enough for preliminary conclusions:

- In the hive, it is necessary to create conditions for the comfortable existence of all members of the bee family.

- It is necessary to take into account the peculiarities of behavior, different sizes of worker bees, drones, queens. Corresponding corrections are made when determining other structural elements with the dimensions of the entrances.

- It is necessary to exclude or minimize harsh odors, noises, and other external influences that can cause disturbance to insects.

- Good insulation will come in handy to reduce heat loss in winter and overheating in summer.

Bee hive device: typical design, features of popular modifications

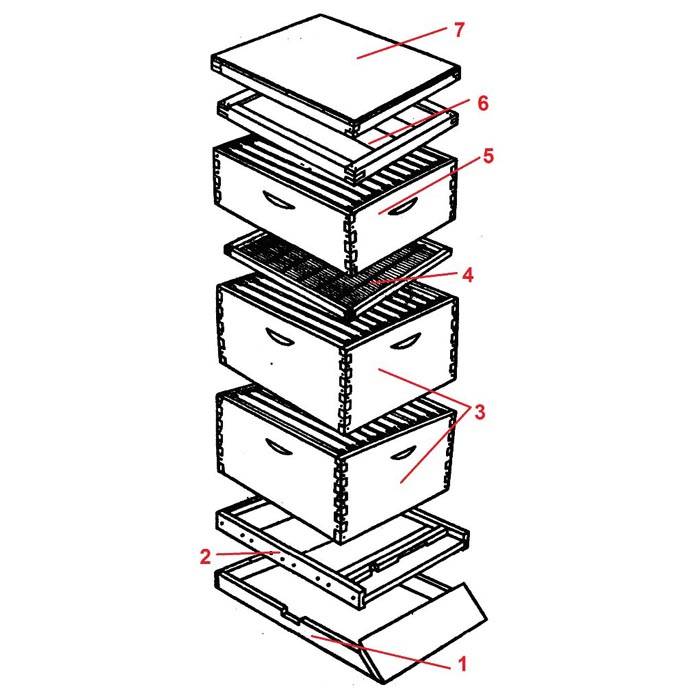

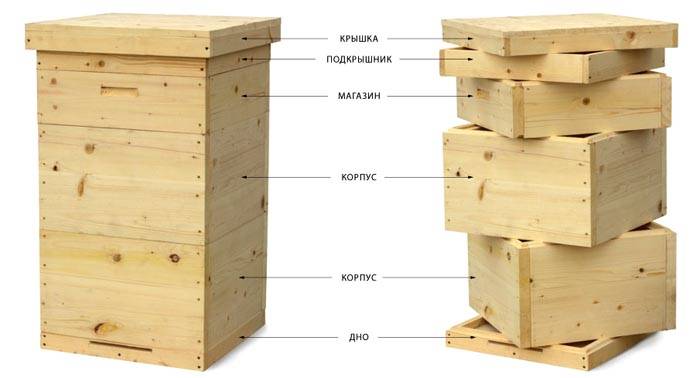

The purpose and special characteristics of individual parts are given below:

- The base (1) ensures the stability of the entire structure. They make it strong enough. Small holes in the side parts are needed for ventilation, which prevents rotting processes.

- The bottom (2) in this hive acts as a transition element and a "take-off and landing" area at the same time. In some designs, it is possible to change the size of the taphole, taking into account the size of the bee colony, season, weather conditions.

- The main part is the body (3). In this project, two identical elements are installed. It is here that the uterus lays eggs. To make it easier to maintain a comfortable temperature, the walls are made thicker, or an additional layer of porous materials is mounted. The frames are placed inside so that there is sufficient space for cleaning at the bottom.

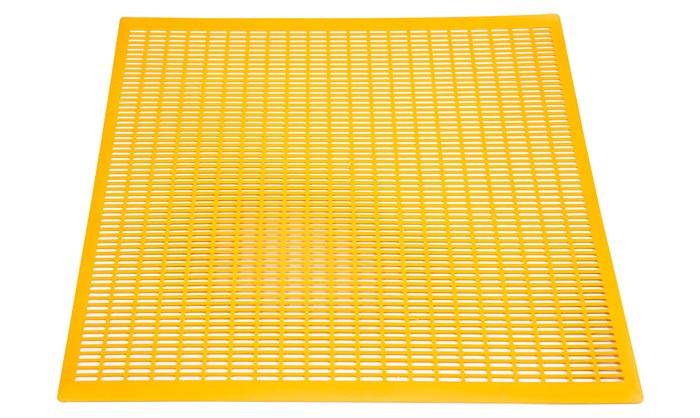

- In the separator (4), the dimensions of the slots are made so that only worker bees can penetrate upward. There is a shop (5) with frames, where honeycombs are created during a bribe. Sometimes this part of the hives is used to place the cuttings in the winter.

- A hole is made in the ceiling (6). It is necessary for ventilation, free movement of bees. On this "floor" feeders are installed, additional elements of insulation in the cold season.

- A cover (7) completes the design. It is upholstered on top with a metal sheet that protects the wooden parts from moisture.

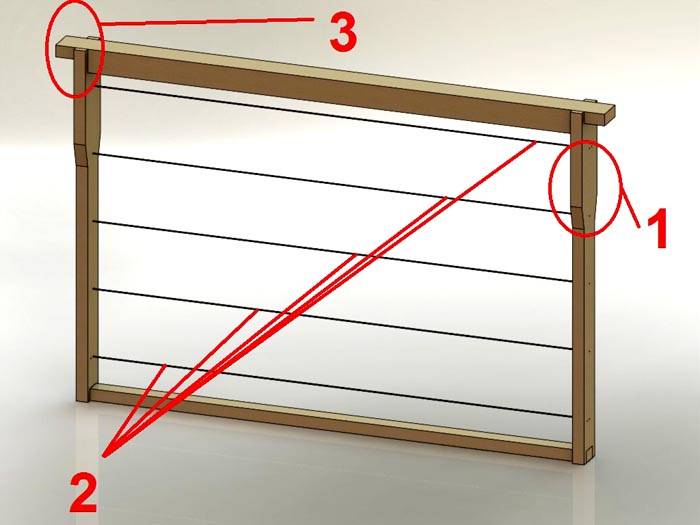

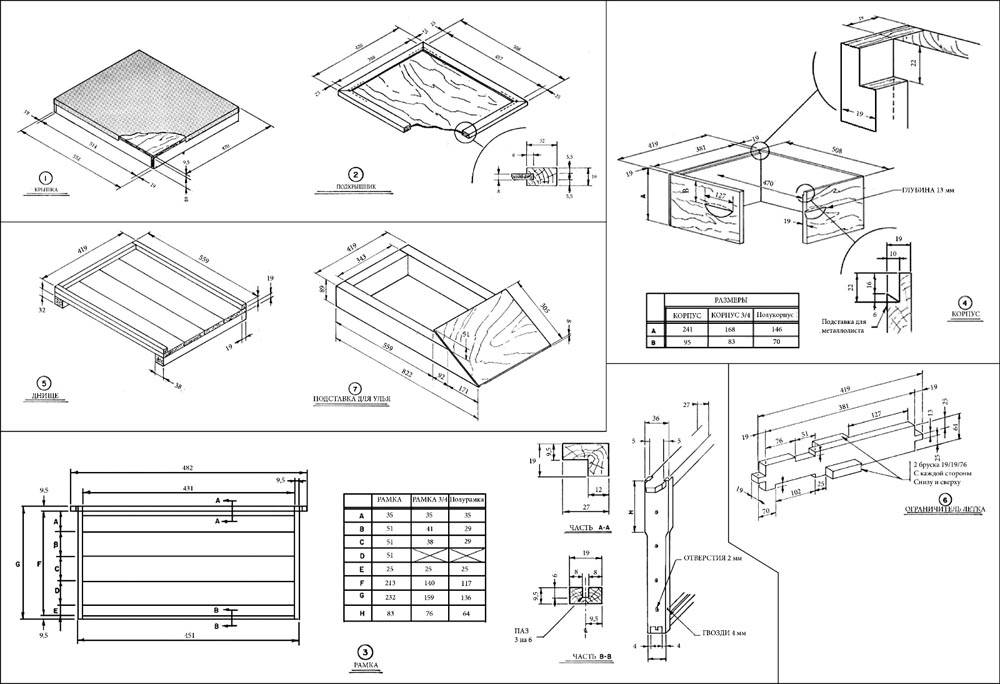

The special shape of the side panels with the expansion of the upper part (1) helps to create gaps of a certain size when installing products in the hive. Strings stretched between them (2) made of fishing line or steel wire facilitate the construction of honeycombs. The elongated elements of the cross bar (3) rest on the walls of the housing during installation.

Note! There are various drawings of bee hives on the Internet, so it is not difficult to find a suitable option. But it must be emphasized that professionals and experienced experts prefer collapsible structures. Such structures are more convenient to operate. In particular, the repair of individual components is simplified.

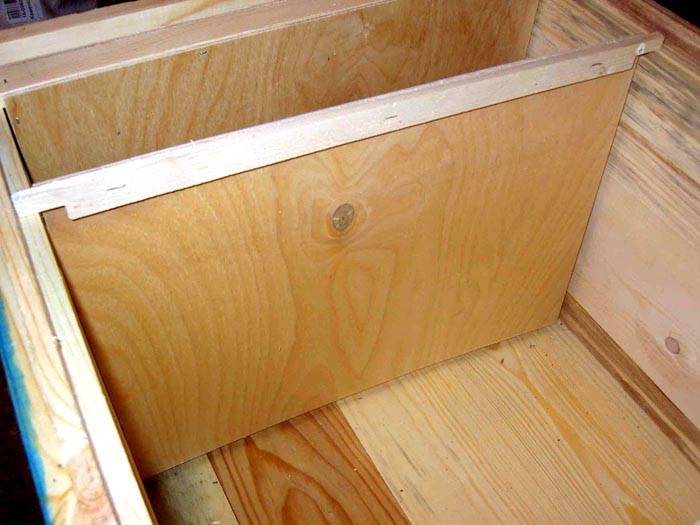

This element is used to divide the hive into functional parts.So, for example, it is possible to create favorable conditions for several bee colonies in one structure.

Note! Instead of plywood, polyurethane foam, chipboard, and other materials are used that meet the above requirements for parts of the hive.

The Dadan-Blatt hive: simplicity and efficiency

Modularity is a clear advantage of this solution. If necessary, you can install a certain number of main buildings, stores. There will be no big difficulties in the manufacturing process, repair.

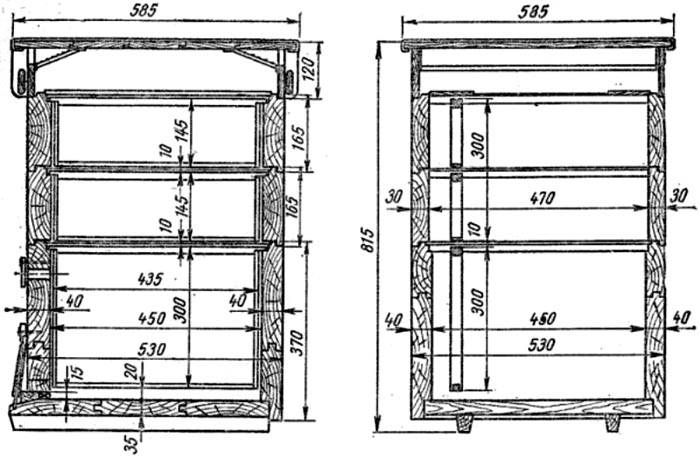

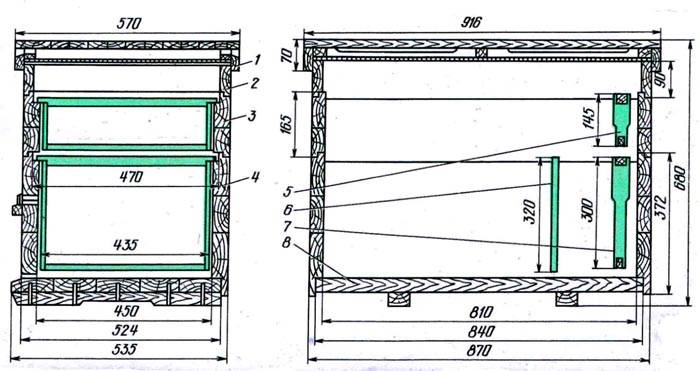

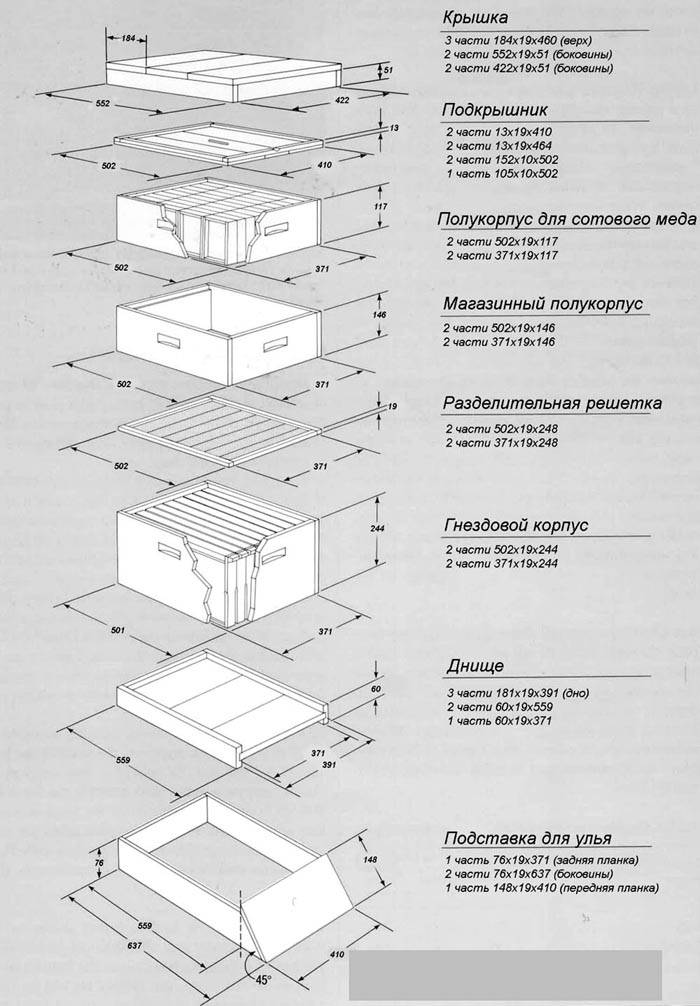

Here are the dimensions of the Dadan hive for 12 frames. The drawing is a working example that has been tested in practice. Some characteristics and details can be changed:

- The roof does not have to be flat. This option is suitable for organizing nomadic apiaries. If you make one or two slopes, raindrops are removed faster from the roof surface.

- The empty space between the bottom of the case and the base is created from 20 mm or more for effective ventilation.

- For the walls of the case / store, it is recommended to take wood 35/25 mm thick. But these standards must be adjusted taking into account the climatic conditions in the region of operation.

- With any number of frames, the following distances to the bottom / side walls / top ceiling are left from them: 20/7/10 mm.

This example illustrates the benefits of improving classic solutions:

- Instead of grooves in the walls, the lower heavy part is equipped with folding metal carrying handles.

- Built-in latches provide secure attachment of parts. But if necessary, they are disconnected without the use of special tools.

- To create the optimal size of the "entrance block", a metal strip with holes was used.

Important! Before changing the standard drawings of the Dadanovsky hive with your own hands, carefully study the recommendations of qualified beekeepers. This will help eliminate mistakes that beginners make with a lack of practical experience.

Langstroth-Ruth hive: how to keep many bees without unnecessary difficulties

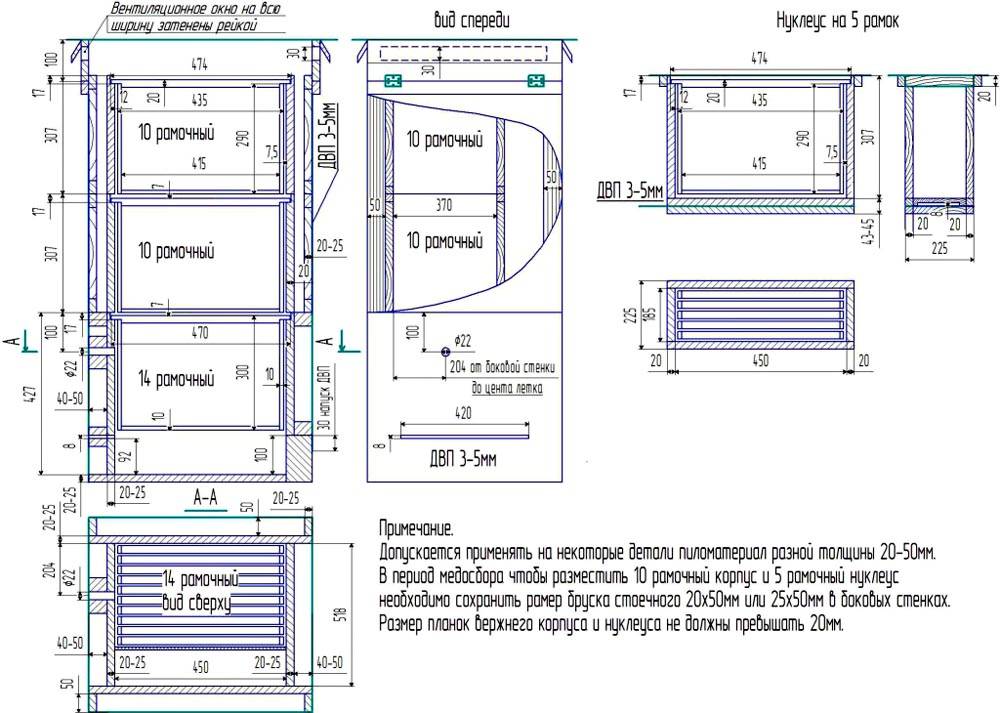

Like other vertical structures, this structure takes up little space on the land. If you apply the option in the minimum version, with one case and a half-shop, it will not be difficult to organize the work correctly. However, experienced beekeepers advise against starting with a large hive. A large store will significantly increase the total volume, which will make it difficult to insulate the nest. Several floors allow you to occupy up to 40 frames, which implies great strength of the bee colony.

From this drawing of the Langstroth hive with two magazines, you can study not only the dimensions, but also the assembly sequence

Note! Professional beekeepers create hives of this type up to 7-8 floors. With their help, they collect over 200 kg of honey in combs in one season.

Horned hive: minimum cost and easy manufacturing

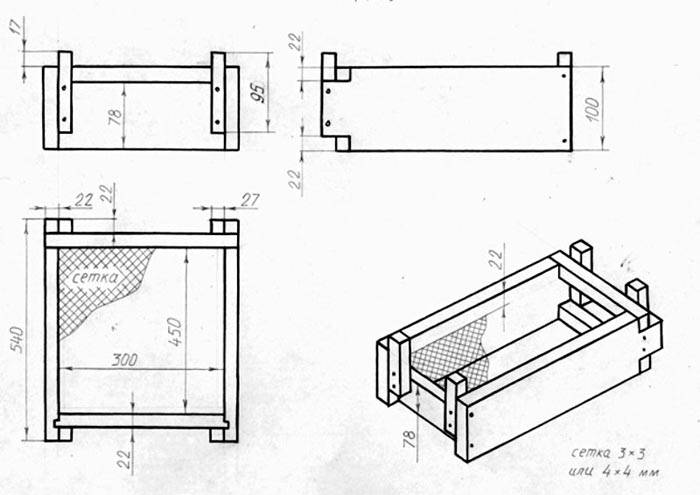

Do-it-yourself drawings of a horned hive explain the main feature - the presence of pins in separate blocks.

Benefits:

- All details can be made using the simplest carpentry tools.

- The design allows for a certain dimensional inaccuracy.

- Assembly and disassembly are performed quickly and correctly.

- Inexpensive materials are suitable for manufacturing.

- Light hives of this type move without much physical effort.

Alpine hive: space saving

Experts claim that the model for this type of construction was the life of a bee colony in a hollow wooden trunk.

The following information will help clarify important features of such structures:

- There are no vents or grilles dividing the total volume.

- The air layer in the ceiling area is moved, which prevents the accumulation of moisture, condensation precipitation.

- During the honey harvest, the family's strength increases. Additional enclosures can be installed to increase productivity and maintain an optimal microclimate.

- In winter, the reverse operation is performed. This makes it easier to create favorable temperature conditions.

- The bodies are divided into volumes of 4-8 frames, taking into account the size of the bee colony.

- The bottom is installed only in the lower block.

- The upper element serves as a drinker and a feeder.

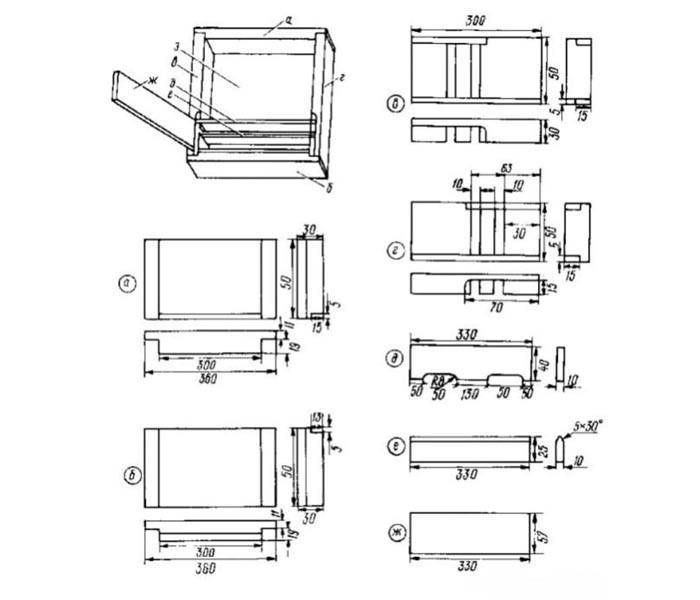

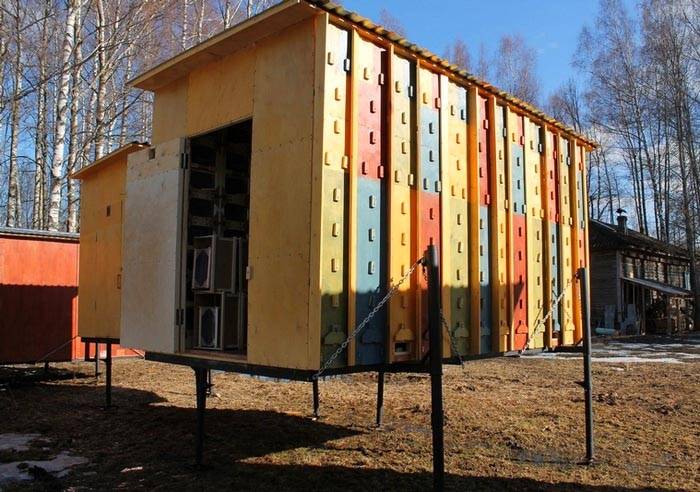

Cassette hive: solving large-scale tasks

In such a structure, bees are kept all year round without seasonal movements. But with the appropriate equipment, transformation into a mobile version is possible.

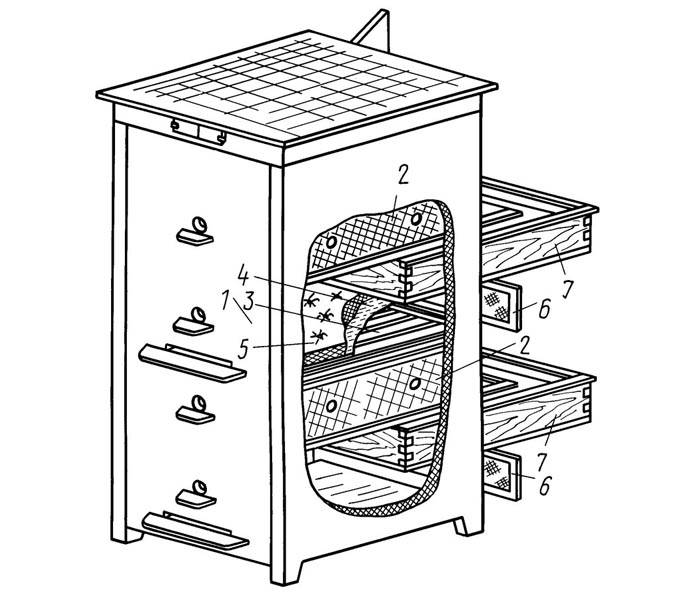

He explains the features of the invention in the field of beekeeping, which is confirmed by a domestic patent. The authors managed to reduce the complexity of maintenance while improving temperature conditions during the cold season:

- Single body (1) provides integrity and high strength.

- Frames (3) are installed in cassettes, which are fixed on runners.

- The protective cover (6) is fitted when rodent protection is required.

- Families of bees are separated by a special panel (4).

- The "cassette" (7) sections provide the passage of fresh air. They are taken out for routine maintenance.

- To improve the insulating properties, a layer of insulation was installed (5).

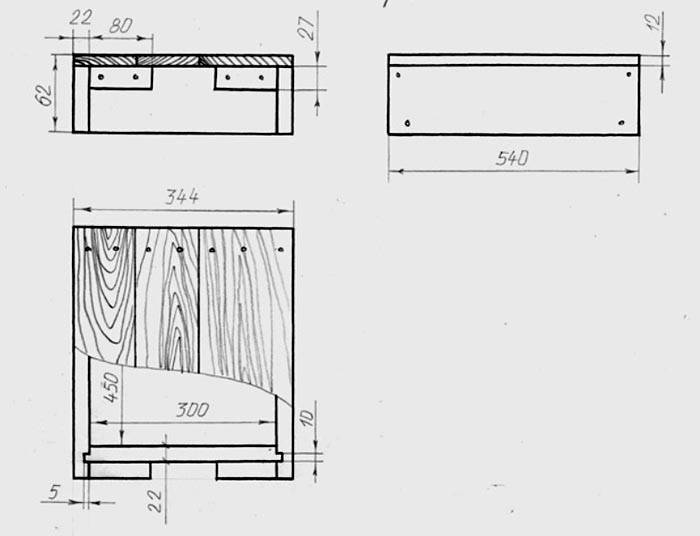

Beehive lounger: comfortable conditions for several bee colonies

This solution allows you to create favorable conditions for the accommodation of several families of bees.

It is best to install this part on the door hinges. As shown in the figure, such equipment will facilitate the manipulation of a rather heavy part during inspection, retrieval of finished products and other work operations.

Beehive boa: description and important details

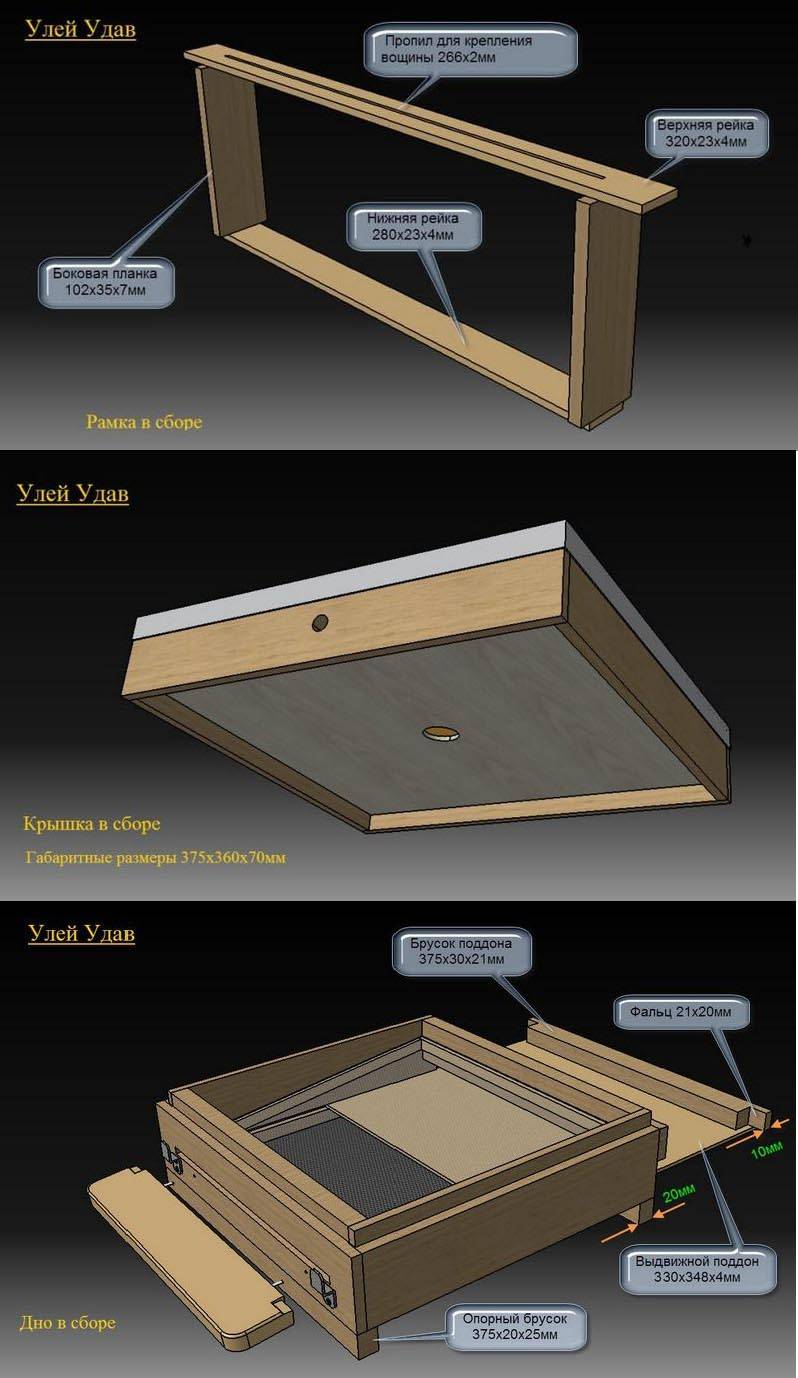

With the help of these drawings, it is not difficult to make a beehive with your own hands. The following comments are also useful:

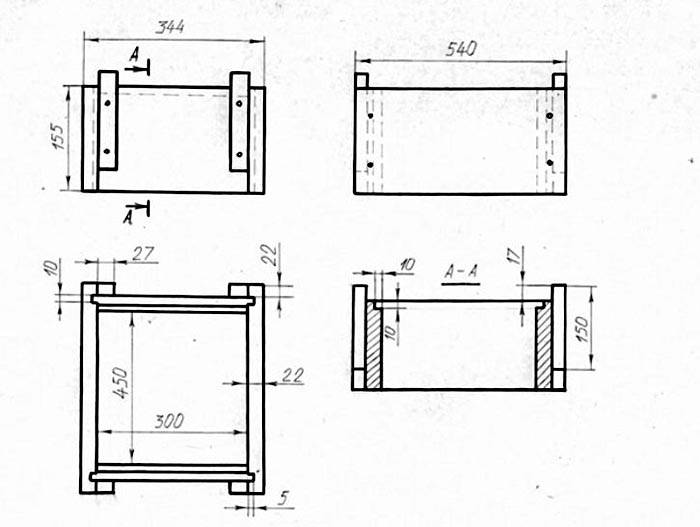

- It is not difficult for bees to fill compact frames with honeycombs, therefore no additional supports (metal strings, plastic threads) are installed.

- To ensure a sufficient thickness of the "air cushion", the height of the walls of the lid is made 25-30 mm, no less.

- Standard cabinet dimensions (width x depth x height in cm): 37.5 x 36 x 13.5. This volume is enough for a maximum of 10 frames. The tap hole diameter is 19 mm.

Work with such hives is organized according to a special algorithm:

- In the cold season, 4-5 buildings are used.

- When spring comes, take out 1-2 lower blocks. This procedure is combined with the replacement of the stretcher, preventive inspection.

- After the first effective bribe, 1-2 cases (frames with foundation) are installed.

- Additional housings are mounted on top as required. As the finished product accumulates, they are removed to pump out honey.

The example above is one option. Beekeepers like the possibility of "flexible" organization of work processes, setting individual parameters for specific conditions. They note positively the following details:

- The compactness and light weight of individual parts reduce labor intensity. They can be removed and carried by one person, without an assistant.

- The absence of wire increases the reliability and durability of the products.

- If you observe the given dimensions of a sheet of standard foundation, there will be enough for four frames without unnecessary waste.

- Small enclosures are useful for creating optimal space for each bee colony.

For an objective analysis, it is necessary to list the disadvantages:

- The small footprint reduces the stability of the structure.

- One frame is easy to make. However, taking into account the total amount required, more time and effort will have to be spent compared to similar products for a typical multi-hive hive.

- Small sections leave a lot of empty space that is not used for its intended purpose (for creating and filling honeycombs).

Related article:

How to make a do-it-yourself birdhouse out of wood. Drawings, materials, decor and installation, as well as many creative ideas on this topic in our material.

How to make a beehive with your own hands: detailed instructions from "A" to "Z"

Before embarking on the implementation of plans, it is necessary to carefully study the peculiarities of beekeeping, weather and natural conditions in the region, and other important factors. It is necessary to clarify how to make a hive with your own hands from different materials. An accurate assessment of financial capabilities, carpentry and other professional skills will come in handy. It would be correct to apply a comprehensive analysis taking into account real initial parameters. It is necessary to take into account not only the main, but also the associated costs, operating costs.

For the correct manufacture of beehives with your own hands, dimensions, drawings, videos and other informational materials in the articles are supplemented with professional comments and useful recommendations. This data will help minimize errors.

Checking different options and creating optimal do-it-yourself hive drawings

You can make notes on the figures that describe the features of materials, assemblies, and other important nuances

If the do-it-yourself drawings of bee hives found roughly correspond to the existing requirements, you need to add your own adjustments. A thorough preparation of a complete set of design documentation will come in handy:

- Check the dimensions of all parts.

- For the correct reading of the drawings, views from different sides, sections of complex nodes are useful.

- It is necessary to write down what materials are suitable for the manufacture of individual elements, are there any alternative options.

- You should step by step check the technology for creating blanks, the assembly process.

- Next, a list of necessary purchases is made.

- This list is used for preliminary price check. If necessary, make appropriate replacements.

Note! If necessary, new professional skills are learned in advance. Training on samples will come in handy so as not to spoil quality blanks and consumables.

Building by stages: algorithm of actions, useful tips

This table shows the process of making do-it-yourself hives. For example, a relatively simple design "Lezhak" was chosen.

Video: how to make quality hive frames

The design, dimensions and other parameters of these products are determined not only by the size of the free space. In some cases, a string support frame is not needed at all.

In this video, making a frame for a hive with your own hands from wooden blanks is described in detail:

This material is easy to process and does not contain irritating and hazardous chemicals. But products made from it are damaged by temperature and humidity. They weigh a lot.

Such products cannot be made at home. Therefore, when choosing this option, you will have to study the range of stores.

Related article:

DIY aquarium made of glass. The necessary information with useful practical advice on lighting, aeration, and other decorative and functional additions is collected in this article.

Conclusions and additional recommendations

Making a quality beehive with your own hands is a difficult but doable task. For simplicity, you can purchase processed blanks, various fasteners, accessories. It will be useful to study the parameters of new insulating materials. In any case, even the most successful projects need to be redone taking into account the real conditions of future operation.