Heat to every home: aluminum radiators

Heating technology manufacturers offer a wide range of batteries from various materials. Among them, aluminum heating radiators are distinguished by the most favorable ratio of such key indicators as lightness, strength and heat transfer. In this article you will find information about the varieties, technical characteristics and features of the use of aluminum heating radiators. Also, the homemaster.techinfolux.com/en/ editorial staff will present a list of the most popular manufacturers, reviews on their products and anti-ratings of companies whose products are not recommended to buy. The analysis of information was carried out on the basis of aggregate consumer reviews taken from Internet resources: Yandex.Market, Otzovik, I-Recommend.

The content of the article

- 1 Aluminum heating radiators: types and characteristics

- 2 Advantages and disadvantages of using

- 3 Application features

- 4 Manufacturers: black and white list

- 5 Popular models and reviews on them

- 6 Selection criteria and calculation of the number of sections

- 7 Features of self-installation of aluminum heating radiators

- 8 Video: calculation of aluminum radiators by area

- 9 conclusions

Aluminum heating radiators: types and characteristics

There are three main types of aluminum radiators. Despite the same raw materials, the manufacturing technology and the degree of purification leads to significant differences in performance, and therefore, in the specific application of these batteries.

Die cast

High-silicon alloy EN AB 46100 (AlSi9Cu2 (Fe)) is used as a raw material, where the silicon (Si) content should not exceed 10-12%. European and most domestic manufacturers use certified primary aluminum in the manufacture of such radiators. This makes it possible to obtain products with the declared strength characteristics and to reduce the risk of corrosion processes. In contrast, almost all Chinese manufacturers use recycled aluminum obtained from scrap. This gives an alloy of poor quality, and the radiators themselves, in comparison with the standard, are more fragile. In addition, due to the high porosity of the material, heat transfer is significantly reduced. At the moment, die-cast aluminum radiators are the most demanded in the Russian market.

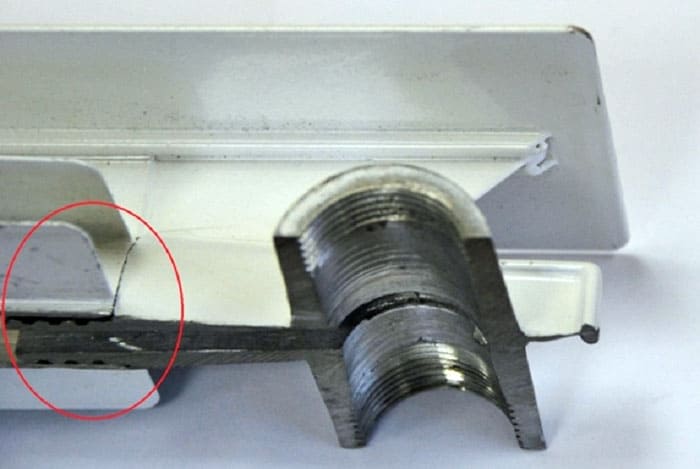

Extrusion sectional

Unlike cast ones, the technology for the production of extrusion aluminum radiators provides for the manufacture of separate elements of the sections, as well as the upper and lower collectors separately. Despite the fact that each part is more durable, multiple joints significantly reduce the overall strength of the product. In addition, some manufacturers use composite glue instead of argon welding to reduce the cost of the production process. These batteries are much more likely to leak, even at standard operating pressure. It should be noted that many retailers mark their extrusion radiators as high pressure castings. It is quite easy to distinguish such products. By the presence of characteristic seams at the junction of the ribs and collectors.

Sectional extrusion aluminum heating radiator. The connection lines of the elements are clearly visible

Anodized

Manufactured from high purity aluminum (up to 98%). The technology provides for anodic oxidation of the entire internal working surface of the radiator. Oxidation changes the structure of the metal surface, as a result of which the product receives protection from almost all types of corrosion. The main technical characteristics of anodized aluminum radiators are significantly higher than those of previous varieties. However, this manufacturing technology is quite expensive, which affects the cost of the final product. Therefore, anodized aluminum radiators are not widely used in the market of heat engineering products in Russia.

A comparative analysis of the main technical characteristics of various types of aluminum radiators is given in the table.

| Radiator type | Performance characteristics | ||

|---|---|---|---|

| Working pressure, atmospheres | Maximum temperature, ºС | Heat transfer (for one section), W | |

| Die cast | 16-20 | 110 | 100-150 |

| Sectional extrusion | 10-40* | 110*** | 80-100 |

| Anodized | 215** | 140 | 150-200 |

* - In practice, the amount of "return" to extrusion radiators is much greater than to cast ones.

** - Most manufacturers of anodized radiators indicate the maximum pressure to break one section. However, prefabricated joints significantly reduce this figure. As a rule, the working pressure does not exceed 50-60 atm.

*** - Extrusion sectional radiators assembled using composite bonding technology have a much lower threshold for maximum temperature, no more than 85-90 ° C.

Anodized radiators can also be produced in the form of panels, which have a fairly wide range of sizes

Related article:

What heating radiators are best for an apartment... In this publication we will consider the types of radiators, their advantages and disadvantages, selection criteria, how to correctly calculate the number of radiators and how to install them correctly.

Advantages and disadvantages of using

The wide popularity of the aluminum radiator has brought undeniable technical and operational advantages:

- high heat transfer in a relatively compact size;

- low weight, which greatly facilitates transportation and installation;

- good ratio of cost and heat transfer capacity;

- aesthetic appearance and durable protective coating (no need for periodic painting).

There are certain technical limitations:

- low resistance to high pressure, especially to water hammer when pressure testing the heating system;

- quality sensitivity coolant.

It should be noted that anodized aluminum radiators are completely devoid of these disadvantages.

On such a parameter as thermal inertia should be dwelt upon. On the one hand, unlike cast-iron radiators, aluminum batteries will not be able to keep the room warm after the boiler is turned off.On the other hand, it provides the broadest possibilities for monitoring and controlling the room temperature. Ultimately, widespread use heat regulators and the economic effect of their use turns the low thermal inertia of aluminum radiators into an advantage.

Application features

As already mentioned, aluminum and its alloys used in the manufacture of radiators are highly sensitive to the quality of the coolant. Namely, its acidity. The normal acidity of the coolant should be in the range of PH = 7-8. In case of deviation from the norm, the protective oxide film is washed out, and as a result of the formation of a new one, hydrogen is released (champagne effect). This causes a lot of troubles, ranging from the formation of air locks to the failure of the battery due to accelerated corrosion. This can be seen especially well in the summer months, when the coolant is drained from the common system, and the pipelines are clogged. The large amount of hydrogen generated simply breaks the housing from the inside.

When choosing aluminum radiators, it is also necessary to consider the working pressure in the system. For centralized networks, the standard is 10-15 atmospheres. However, this is the working pressure. When starting and checking heating systems for leaks, the pressure test is increased up to 1.5-2 times. Thus, for apartments with a centralized system, only anodized aluminum radiators are allowed.

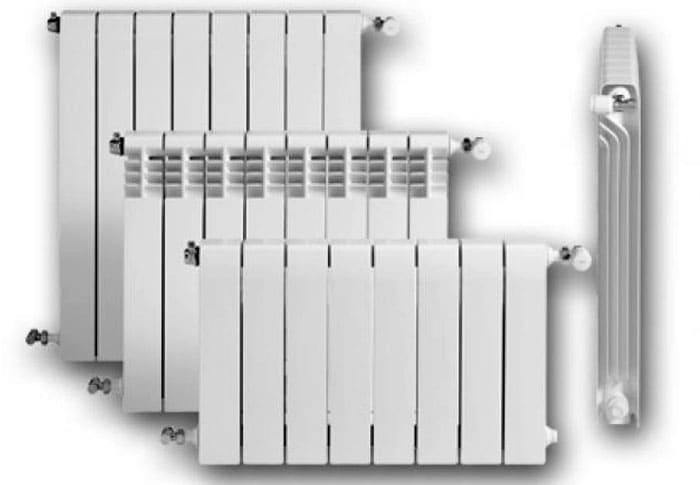

Aluminum radiators are available in the widest range of sizes. In addition, you can add and remove sections yourself, optimizing the heat transfer of the battery.

In individual heating systems, the operating pressure rarely exceeds 1.5-2 atm. Therefore, any type of aluminum radiators can be used there.

Galvanic couple effect. There is a fairly well-founded opinion among engineers and thermal installers that aluminum radiators cannot be used in conjunction with boilerswhich are equipped with copper heat exchangers. The reason is the formation of an aluminum-copper galvanic pair, which leads to electrochemical corrosion. In the case of its formation, copper attracts aluminum ions, and, literally for several years of operation, aluminum on the radiator turns into foil.

Galvanic couple effect. The intense release of hydrogen can not only destroy batteries, but also cause a fire

However, this effect can only be achieved in the case of direct contact between copper and aluminum. If PVC pipes are used to transfer the coolant or special cadmium, chrome or nickel-plated adapters are used during installation, then the galvanic pair breaks.

Manufacturers: black and white list

Of the main manufacturers whose products are deservedly popular, many Italian firms can be noted:

- Global;

- Fondital;

- Nova;

- Florada;

- Radiatori;

- Sira.

Also noteworthy are the products of the Hungarian company. Nami.

Of domestic companies, it is worth noting radiators from Anchor, Rifar (under the Global license) and Thermal.

Some Chinese manufacturers operating under the Global license were also whitelisted: Alltermo, Tianrun.

Also, we want to draw your attention to the list of companies (mainly Chinese), about whose products we found the most negative reviews:

- Oasis;

- Konner;

- Radena;

- Warma.

In addition, during tests carried out in 2018 in the Moscow laboratory "Vitaterm", in the products of the listed companies, inconsistencies in real parameters with the declared indicators were found from 22% to 34.75%.

Popular models and reviews on them

The homemaster.techinfolux.com/en/ editorial staff presents to your attention some consumer reviews on the most popular models of aluminum radiators:

Feedback on the operation of Lammin aluminum radiators:

Review of aluminum radiator "Konner":

Review of the aluminum radiator "Royal Thermo Evolution 350":

Review of aluminum radiator "Mirado Al 500/96":

Feedback on the operation of the "Monlan" radiator:

Selection criteria and calculation of the number of sections

When choosing an aluminum heating radiator, pay attention to the following parameters:

- the presence of a protective oxide film or additional processing on the inner surfaces;

- mandatory presence of a technical passport for products indicating the main technical characteristics;

- the seller has a certificate of conformity to exclude the purchase of counterfeit products;

- as a rule, prefabricated heating radiators are supplied in 10 sections. Some manufacturers offer radiator options from 3 to 15 sections. Remember that factory assembly is more reliable than home assembly. Therefore, it is advisable to purchase assembled batteries;

- if, according to calculations, a radiator with more than 10 sections is needed to heat the room, then it is more efficient to purchase two batteries with the corresponding number of sections;

- most European manufacturers are very jealous of the quality of their products, so they order various expertise. The presence of an independent test report is a significant advantage of the products of this manufacturer.

Important! It is strongly discouraged to purchase aluminum radiators (mainly made in China) marked with NF / 68 /. Research conducted by the independent laboratory AIRAL has identified a critical asbestos content in such products.

When determining the number of sections for heating a room, the following nuance must be taken into account. Manufacturers indicate the heat transfer rate of one section at a certain temperature. As a rule, it is 70-75 ° C. However, in most cases, the temperature of the coolant in heating systems rarely rises above 60 ° C. Therefore, the indicator indicated in the technical passport must be reduced by 15-20%.

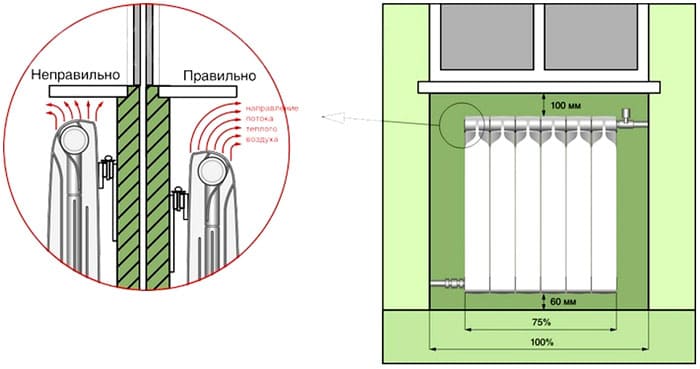

Features of self-installation of aluminum heating radiators

If the pipes of the heating system have appropriate threaded fittings, then you can replace any radiators with aluminum ones with your own hands:

- first of all, it is necessary to shut off the heating circuit and drain the water;

- on the purchased radiator, you need to find the plugs and pull them out;

- if the heating system is one-pipe, it is mandatory to install bypass... If it is two-pipe, then you can do without it;

- to connect the radiator, it is used in a squeegee with a valve, which is screwed in with pipe wrenches;

- tow or more modern sealing materials are used to seal the threaded joint: unipack, silicone tape, etc.;

- the packing shell is removed only after all installation work is completed, which will protect the front panel from damage.

For positioning on the wall, it is better to purchase brackets with the ability to adjust the height of the position

Video: calculation of aluminum radiators by area

conclusions

Undoubtedly the most popular are high-pressure die-cast aluminum radiators. They are less expensive than anodized but can be used in almost all systems, including multi-family homes.