Corrugation for hoods is a mandatory element of the ventilation system of a residential building

When installing the ventilation system, special structures are used, called air ducts, without which the operation of such equipment is impossible, regardless of its location (residential building, apartment, industrial facility). When installing additional equipment located in the kitchen or bathroom, providing the necessary air circulation, flexible air ducts are used, which simplifies their installation and further operation. Corrugation for hoods - advantages and disadvantages, how to choose and install yourself, as well as how to care for, and at what price you can buy profitably - this is the topic of this article.

The content of the article

- 1 What is corrugation, and why is it needed for exhaust devices

- 2 Advantages and disadvantages of corrugated pipes for ventilation

- 3 Technical characteristics of corrugated pipes for extraction

- 4 What types of corrugations are used for home hoods

- 5 How to choose a corrugation for a hood - our editorial team's recommendations

- 6 Installation of corrugated air duct for exhaust

- 7 The nuances of performing the installation of corrugated air ducts

- 8 How to care for the air duct, and when you need to replace the corrugated pipe for the hood

- 9 Comparison of flexible corrugation for ventilation with rigid duct

- 10 Where is it profitable and at what price can you buy a plastic and aluminum corrugation for a hood - an overview of proposals

- 11 Video: organizing the hood in the kitchen

What is corrugation, and why is it needed for exhaust devices

Corrugation is a corrugated pipe used in the installation of air ducts, installed between the equipment that provides circulation and room air extraction, where they are installed, into the ventilation system of the building or directly into the external environment.

The corrugated pipe for extraction is a flexible element due to its design and production technology. Due to its mobility, the corrugation is used when installing air ducts in hard-to-reach places and in areas located in curved and perpendicular planes of space.In addition, due to their attractive appearance, certain grades of corrugated pipes made of stainless steel and aluminum are used along the entire length of the duct without additional decoration and cover.

Corrugated air ducts are used to connect the kitchen hood and axial fansinstalled in a bathroom or a toilet, when installing gas water heaters and heating boilers of various types.

Advantages and disadvantages of corrugated pipes for ventilation

The appearance of freely accessible corrugated pipes had a positive effect on the quality and availability of work, providing the necessary microclimate in the equipped premises. This is due to the fact that when constructing rigid structures, practiced earlier, it was necessary to order from specialized organizations an individual structure (air duct) for a specific room - accordingly, it was expensive and not available to everyone.

The advantages of corrugated pipes used in ventilation systems are:

- long service life;

- ease of installation;

- availability;

- a wide range of standard sizes;

- strength, excluding certain models;

- ability to withstand high temperatures and not sustain combustion;

- good aerodynamic characteristics;

- light weight.

The disadvantages include difficulties in maintenance, expressed in cleaning the surface corrugations, as well as the softness of products made of aluminum, leading to a violation of the geometric shape during careless installation and maintenance.

Technical characteristics of corrugated pipes for extraction

The main technical characteristics of the corrugation used for the hood are its dimensions - diameter and length. The length is specified by the manufacturer and can be a standard size or sold in coils, which allows you to purchase a duct of the required length.

In cross-sectional shape, the corrugation can be rectangular or round. Rectangular models are generally only used in manufacturing facilities. The diameter of the produced air ducts is standard: 10/12 / 12.5 / 15/20 cm, as well as 30 cm or more, but these are dimensions that are not related to the standard of similar products. For the manufacture of corrugated air ducts, plastic and aluminum, stainless and galvanized steel, as well as textiles and polyethylene are used. By their design, such products are of frame and spiral-wound type.

What types of corrugations are used for home hoods

When installing ventilation systems in residential premises, corrugated round-shaped spiral-wound air ducts are used, made of plastic and aluminum, stainless and galvanized steel.

Aluminum corrugated pipe

This type of corrugation can be used for indoor installation and outdoor use. Distinctive features of this type are: low weight and medium-hard frame. The advantages of an aluminum corrugated duct include long service life and the ability to use it at different temperature conditions. The disadvantages are: an increased noise level that occurs in the inner space of the corrugation when the hood is operating at high speeds, as well as the presence of vibration during use.

Plastic corrugation for ventilation

Plastic corrugated air ducts are characterized by low cost and ease of installation.In addition, the advantages of this type include: the minimum resistance to air flow created in the inner space of the pipe, as well as a variety of models that differ in technical characteristics.

The disadvantages of plastic corrugation are:

- flammability;

- when ignited, it emits a significant amount of smoke that is harmful to human health;

- susceptibility to destruction under external mechanical influences (fragility);

- the presence of a specific odor that appears during operation, due to the increased temperature of the circulating air, - for the cheapest models.

Related article:

Plastic air ducts for ventilation. In the publication, we will consider an overview and characteristics of plastic air ducts, their pros and cons, the nuances of a plastic ventilation device.

Other types

Other types of corrugated pipes that are used less often than those discussed above include products made of stainless and galvanized steel.

The advantages of such materials are:

- long service life;

- strength and resistance to external mechanical stress;

- not flammable;

- lack of smell during use;

- nice appearance, and for galvanized models - a variety of colors and the availability of models coated with polymer materials.

Among the disadvantages, it should be noted the high cost and complexity of installation work.

Related article:

Cooker hoods with ventilation outlet are considered to be more efficient, emit less noise and provide the air exchange required by building codes. How to choose them correctly and carry out the installation yourself - read the material.

How to choose a corrugation for a hood - our editorial team's recommendations

When buying a corrugated air duct for an exhaust hood, the main criteria that influence the choice of a particular model are:

- Specifications - diameter and length.

- The material from which the product is made and its compliance with the interior of the room where the installation is supposed to be performed.

- Quality and reliability.

- Cost.

In addition, the specialists of our editorial office recommend that when choosing a corrugation for an exhaust hood, pay attention to the following nuances:

- the diameter of the corrugation must correspond to the diameter of the hood and the recommendations for its connection specified in the operating instructions;

- the length of the air duct should be as small as possible, taking into account that the configuration “fractures” should not exceed an angle of 90 °;

- quality and reliability - does not guarantee the cost of the product, therefore, when choosing a model, it is necessary to check the quality certificates, as well as familiarize yourself with the reviews of experienced users about a specific manufacturer of such goods.

Installation of corrugated air duct for exhaust

Installation work on the installation of the air duct can be divided into two stages: preparatory and work execution. At the preparatory stage, the brand and dimensions of the corrugated pipe are selected, it is purchased, after which the necessary tool is prepared.

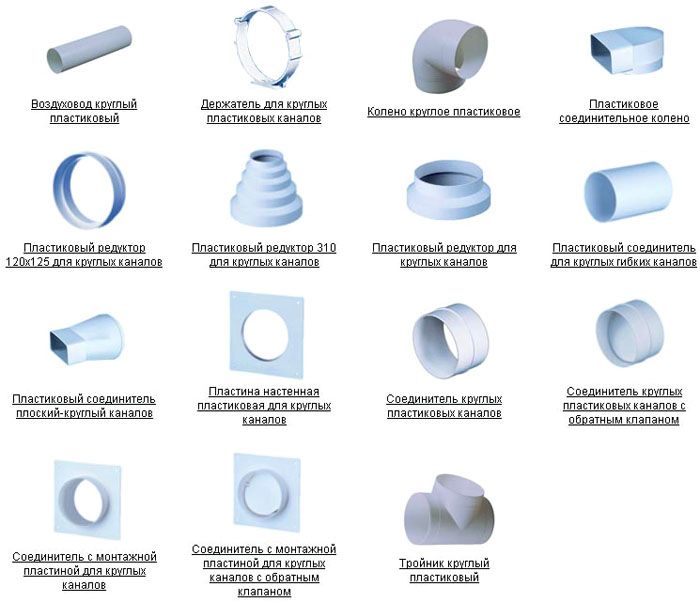

Important! When buying an air duct, remember that you should also purchase adapters and elements for its fastening and connection.

To carry out installation work, you may need:

- electric drill or screwdriver;

- tape measure and pencil;

- a hacksaw for metal or scissors;

- screwdriver.

Work on installing the corrugation on the hood is performed in the following sequence:

As you can see from the step-by-step instructions, it is quite simple to install the corrugation on the hood in the kitchen, therefore each user can perform this operation independently, without the involvement of specialized organizations and qualified specialists.

Related article:

For those who don't know how to choose a hood for the kitchen, professional advicediscussed in this article will help you make the right choice. You will learn by what criteria it is necessary to select a device, which will make it easier to navigate the range offered by manufacturers.

The nuances of performing the installation of corrugated air ducts

Sometimes, when performing installation work, non-standard situations arise that require separate consideration: the need to connect the corrugation or hide it from the visual space of the kitchen area.

How to connect with each other

The need to connect several corrugation elements to each other arises in the case of an extended section of the air duct, which cannot be completed entirely. For the connection, special inserts are used (indicated by an arrow in the following figure), installed in the inner space of the corrugated pipe in both abutting elements, after which the joints are pulled together using clamps.

If the inserts are not available, due to non-standard dimensions of the ducts or for other reasons, then the connection can be made using construction tape corresponding to the material from which the duct is made.

How to hide corrugation in the kitchen

There can be a large number of options on how to hide a corrugated air duct in the kitchen, as evidenced by the following photos, which recorded the solution to a similar problem by designers and tenants:

- The air duct is closed by the doors of the wall cabinets

- The duct is mounted behind a plasterboard structure

- The air duct is covered with a decorative box

- The air duct is closed with a decorative box in the style of kitchen decoration

- Corrugation for false ceilings

- Covering the duct with a decorative element

How to care for the air duct, and when you need to replace the corrugated pipe for the hood

Maintenance of a corrugated pipe is no different from other work related to maintaining cleanliness in the kitchen space, which is expressed in the removal of dust and other suspended particles from the outer surface of the air ducts. In case of severe contamination (tobacco smoke, fat), to wash the outer surface of the corrugation, it must be dismantled and then returned to its original place after performing the necessary work.

The tightness of the connection ensures the maintenance of an optimal microclimate in the kitchen and the extraction performance declared by the manufacturer

It should be noted that after a certain period of time, this is usually about 10 years (depending on the intensity of use of the hood), fat accumulates in the inner space of the corrugation, which cannot be washed off. In this case, it is necessary to replace the air line in order to avoid the dangerous consequences of its use. In addition, when operating such systems, the following safety rules must be observed:

- do not touch with wet hands the surface of the corrugation made of steel and aluminum during the operation of the hood;

- to prevent the appearance of foreign odor, it is not recommended to wipe the outer surface of the air ducts using detergents.

For fastening, connection of corrugated pipelines, various fittings are used that correspond to the technical characteristics of the installed ventilation system

Related article:

Built-in hood 60 cm is the perfect solution for any interior. If you do not know how to make the right decision, then our review will help you do it. We will consider the main criteria for choosing such equipment, and also learn how to install it correctly.

Comparison of flexible corrugation for ventilation with rigid duct

If we compare flexible air ducts with rigid ones, then the former have a number of indisputable advantages, which include the following indicators:

- elasticity and flexibility allow them to be used in complex areas of ventilation systems, in different placement planes, while with a minimum number of fastening elements;

- lightness of structures and, at the same time, strength;

- ease of installation work;

- small overall dimensions in transport position (compressed state);

- functionality for indoor and outdoor installation.

Where is it profitable and at what price can you buy a plastic and aluminum corrugation for a hood - an overview of proposals

The corrugation for the hood is sold in specialized plumbing stores, as well as trade organizations that sell household appliances and ventilation systems. In addition, such goods can be purchased through online purchases on the Internet, where a fairly large number of companies offer similar products for sale.

The following table shows the cost for different types of corrugation, as of the II quarter of 2018, when sold in retail chains.

| Material | Product | Size (diameter / length), mm | Trade Organization | ||

|---|---|---|---|---|---|

| www.maxidom.ru | www.petrovich.ru | www.leroymerlin.ru | |||

| Aluminum | Corrugation | 100×3000 | 116 | 108 | 110 |

| 125×3000 | 149 | 144 | 166 | ||

| 150×3000 | 191 | 176 | 184 | ||

| Foil | 100×3000 | - | - | 398 | |

| 125×3000 | - | - | 474 | ||

| 150×3000 | - | - | 618 | ||

| Polymer | 102×10000 | - | 416 | - | |

| 127×10000 | - | 569 | - | ||

| 152×10000 | - | 687 | - | ||

| Steel | Clamp | Ø110-130 | 38 | 63 | 45 |

| Ø120−13 = 40 | 51 | 75 | 64 | ||

| Ø140-160 | 53 | 87 | 73 | ||

| Steel | Connector | Ø100 | - | 109 | 62 |

| Ø120 | - | 134 | 78 | ||

| Ø150 | - | 183 | 118 | ||

| Plastic | Reducer | Ø80 / 100/120 / | 63 | 94 | 75 |

| 125/150/160 | |||||

| Holder | Ø100 | 53 | - | 61 | |

| Ø125 | 126 | - | 97 | ||

| Ø150 | 118 | - | 104 | ||

The best place to purchase ventilation equipment and components for them are large trading companies, because in such organizations, as a rule, a wide range of similar products is presented, allowing you to choose the right material in accordance with the requirements for it, as well as with the financial capabilities of the buyer.

Flexible air ducts are a reliable and proven element of a ventilation system for domestic and industrial use