Check valve for ventilation: selection rules, manufacturing and installation of the structure with your own hands

To prevent air from moving in the wrong direction, a special device is used. A check valve for ventilation is installed in forced and natural systems. You can buy it in the store, or create it yourself. If necessary, the installation is not difficult to carry out without assistance. This article will help to solve the indicated tasks quickly, correctly and inexpensively.

Even such a light barrier is sufficient to prevent air from entering the room from the ventilation duct.

The content of the article

- 1 What is a check valve for ventilation: problems and how to fix them

- 2 The device and principles of operation of the check valve for ventilation

- 3 Different types of check valves

- 4 Check valve application in the kitchen

- 5 Correct use of the valve in plumbing

- 6 Ventilation devices equipped with a non-return valve

- 7 DIY check valve process

- 8 Buying a finished product without mistakes: market overview

- 9 Correct installation of the non-return valve for ventilation

- 10 Conclusions and additional recommendations

- 11 Video: hood and non-return valve, principle of operation and installation

What is a check valve for ventilation: problems and how to fix them

Signs of a malfunction of the system are foreign odors coming from other rooms (apartments in a multi-storey building). Penetration of cold air in winter disturbs comfort and increases heating costs. Together with the return flow, various impurities from ventilation systems... Some of them can be harmful to health.

It is clear that it is better to eliminate such shortcomings. But first you need to figure out the reasons for their appearance.Some of them can be eliminated to improve the functional state of ventilation.

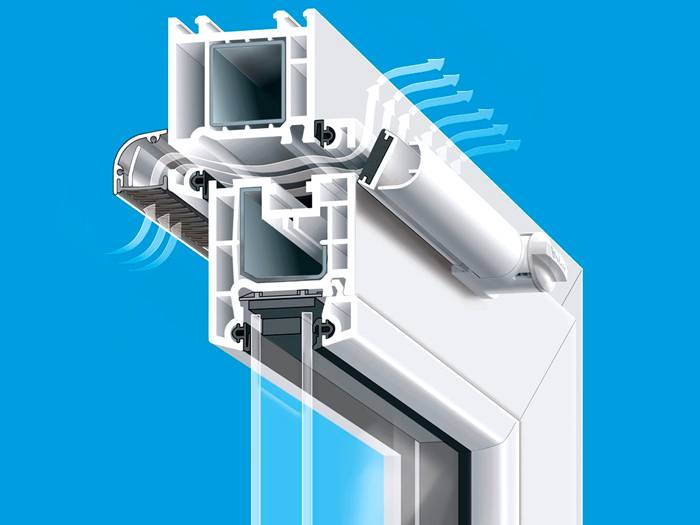

Sometimes problems arise after replacing old frames and installing double-glazed windows. New window blocks provide perfect tightness, completely blocking the access of fresh air to the room.

As a rule, filters are installed in these products, which can become clogged over time. Regular inspection and cleaning will help restore lost functionality in full.

A change in the direction of the air flow can occur when several sampling points are connected to one duct. Similar manifestations are not excluded in strong winds, in frosty weather. It is especially difficult and even impossible to influence the actions of neighbors in an apartment building. Claims to them can be made only if the air duct is completely blocked. If smells come from someone else's kitchen, where he works powerful hood, the problem will have to be solved independently.

Related article:

Inlet valve into the wall. In our review, you will find out what the valve is for, the principle of its operation, the device, the advantages and disadvantages, an overview of finished models, self-production, features of the installation of the air duct.

The device and principles of operation of the check valve for ventilation

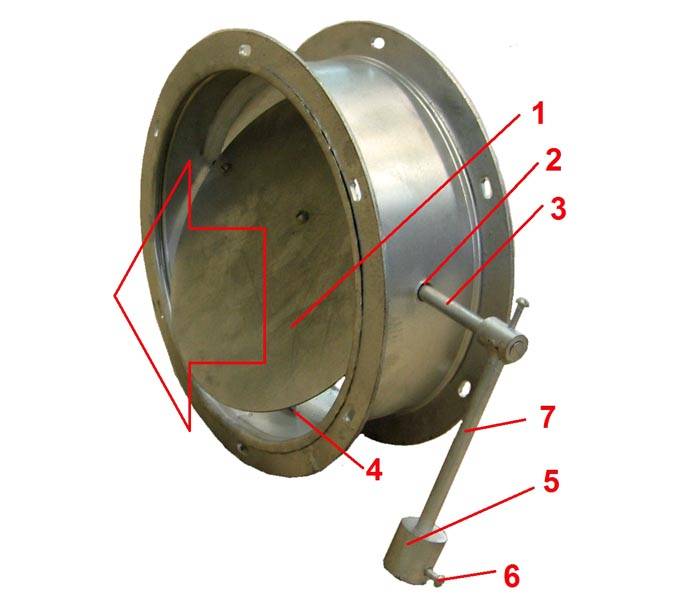

This industrial ventilation air valve functions as follows:

- When air flows in the direction indicated by the arrow, the damper (1) opens slightly.

- It is fixed on a metal shaft (3) installed in the holes in the body (2).

- Under the action of the force created by the load (5), the disc returns to its original position. Using the screw (6), this part can be positioned in the desired location of the auxiliary rod (7) to change the sensitivity of the device.

- In the lower position, the disc rests on the retainer (4).

Using the example of this ventilation check valve, individual disadvantages can be noted in order to more accurately formulate the requirements for the parameters of high-quality equipment:

- There is an adjustment mechanism here. However, it is not intended for installation in residential ventilation ducts hidden inside building structures.

- There are no bearings in the center axle mount. It is possible that during the operation of this ventilation check valve, extraneous noise will appear. They will be difficult to remove with lubrication, even if the appropriate procedure is performed regularly.

- There are no seals here, so it will not be possible to completely block the air flow in the opposite direction. If technological gaps are not left, the risk of damper seizure increases.

This product is made of sheet steel, which increases strength (not needed in this case), increases weight. Conventional paint does not meet modern requirements for good corrosion protection. The listed facts must be taken into account when creating a design with your own hands, in the course of choosing a suitable model in the retail network.

Different types of check valves

A heating element is installed in this valve along the circuit. It ensures the maintenance of performance in conditions of high humidity, low temperature

In this article, the scope of the study is limited to household models. These products do not need to be connected to power supplies. Their installation will not cause difficulties for an ordinary user.

Membrane construction: simple and cheap

The principle of operation of a diaphragm check valve is not difficult to understand by studying this photo.The working opening is covered with a flexible plastic film that adheres tightly to the base in the corresponding direction of flow. Choose a flexible but strong enough material. Having chosen the right stiffness, it is possible to set the required sensitivity level. Such an overlay can be fitted to an existing system (fan, grill). There are no mechanical parts and complex mechanisms, which means reliability and durability.

This "butterfly" does not fly, but performs its functions flawlessly in any position

In this version, the main functions are performed by the petals fixed on the central axis. They are held down by springs, therefore significant force is required to open the channel. Such products are installed in forced ventilation systems. Some models are equipped with special devices for adjusting the springs (increasing / decreasing the force of action).

This modification is made of galvanized steel. It is resistant to corrosion processes and weighs a little. A soft damper is fixed on the surface of one plate, which prevents strong shocks and noises.

Features of petal valves

The simple design of the petal check valve for ventilation is one of the main advantages of this product category. The sash is pulled down by gravity. Its relatively low weight does not create much resistance to air flow, therefore installation in natural ventilation systems is permissible.

Note! It should be noted that this model should be installed only in a horizontal channel. For vertical lines, products with springs (counterweights) are used, which provide a forced return of the damper to its original state.

Check valve application in the kitchen

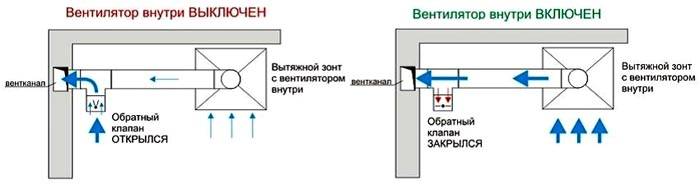

With this setup hoods for kitchen with a non-return valve, ventilation operates continuously. If you turn on the desired fan speed, the debris removal speed will be increased. Of course, one must not forget about creating a sufficient supply of fresh air.

Note! To increase the efficiency of the system, the length of the channel is reduced, and the exit to the street is made directly in the wall of the room. In this case, it is equipped with an additional valve that blocks the flow of air from the outside along this path.

Ventilation with a non-return valve in the kitchen can be supplemented with an extractor hood that operates on the total volume of the room

Important! When choosing a suitable product, you should pay attention to models that are easy to clean, resistant to fats and other specific dirt.

Correct use of the valve in plumbing

For installation in these rooms, structures that are resistant to high humidity are used. We must not forget that powerful agents are used to remove calcium and other persistent formations. The acids and other aggressive chemical compounds they contain are released into the air. They can damage decorative and protective layers, metal parts, welded joints.

The characteristics of the plastic check valve for ventilation in the bathroom correspond to the conditions of future use

Ventilation devices equipped with a non-return valve

This section of the article discusses various combined products. They perform their functions in conjunction with a valve that prevents air back movement. In some cases, they are equipped with serial models to improve the original consumer characteristics.

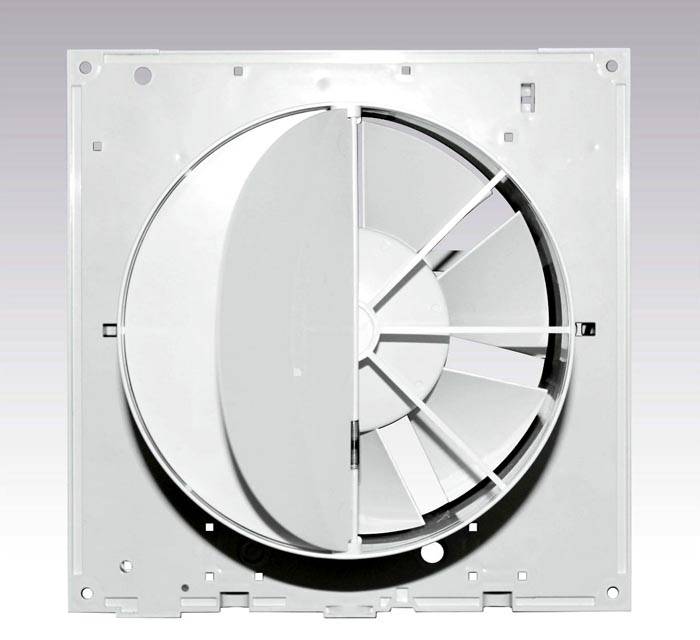

Exhaust fan design with check valve

IN this design petals are pressed by built-in springs.The parameters of these return mechanisms are calculated at the design stage. They correspond to the performance of the equipment (force of air flow). If it becomes necessary to replace a broken part, a new spring is selected with similar characteristics. This design with a large number of plastic elements is well suited for bathrooms. However, it is useful to check the manufacturer's recommendations, the protection class of the electrical device, taking into account the high humidity in the room.

Note! Mounting the fan on a hood with a spring-type check valve is permissible in horizontal and vertical position. This universal drive retains the same functionality in any position, at different angles of inclination.

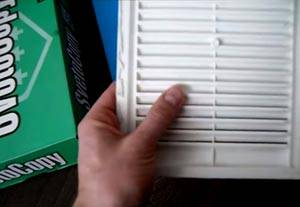

Ventilation grill with a non-return valve: affordable cost - excellent result

This ventilation grille with a non-return valve contains several leaf elements. This solution is used when overlapping large channels. Single parts that are too large are heavy, which does not allow the sensitivity to be reduced to a level that meets the requirements for natural drawing. But when choosing such a model, it is necessary to clarify the tightness of the joints in the closed position of numerous dampers.

The ventilation grill with the valve is selected taking into account the size and shape of the channel

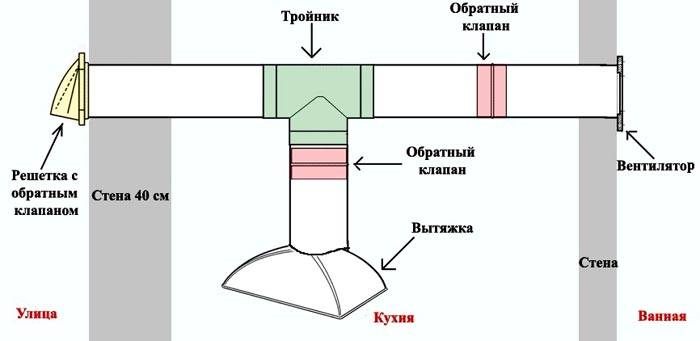

The principle of operation of the tee with a check valve

So you can create a project when connecting several points of air intake from one or several different rooms.

The use of a tee for the exhaust hood with a check valve prevents the flow of air from the duct into the kitchen. Another device performs similar functions. It can be installed differently from the picture, but in combination with a fan.

Advantages of a check valve on the exhaust

Installing an exhaust check valve prevents various contaminants from entering the engine from the ventilation duct. This extends the service life of the equipment.

An exhaust hood with a check valve prevents the penetration of unpleasant odors from other rooms, apartments when the system is connected to a common ventilation duct

Note! Some users fear that the spring actuator and the weight of the dampers will reduce the performance of the venting system. This is not true. These loads are insignificant in comparison with the power of the fans, which are equipped with modern equipment of this class.

If there is no such device in the set from the manufacturer, you can install the anti-return valve for the hood yourself. What it is is not difficult to understand from the materials of the article. Below are instructions for self-creation of functional products and features of installation operations.

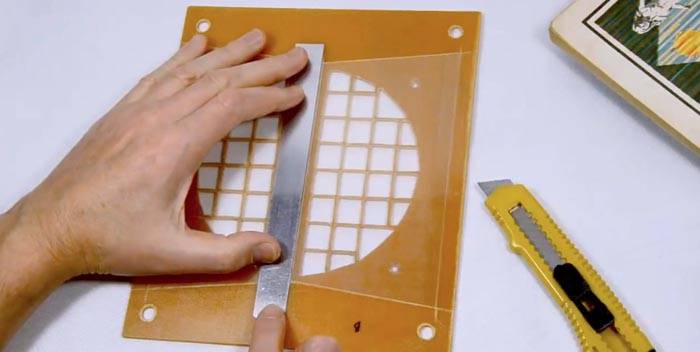

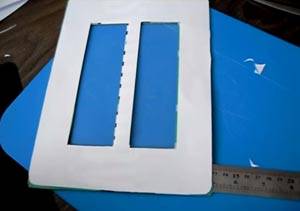

DIY check valve process

Buying a finished product without mistakes: market overview

It will be easier to buy a check valve for ventilation after reading the data from this table:

Note! It should be noted that it is not so easy to buy a plastic check valve for ventilation due to the limited supply on the market. That is why you have to create the necessary products yourself, taking into account individual needs.

Correct installation of the non-return valve for ventilation

In a simple system with one pick-up point and direct access to the street, one device of this type is sufficient.

Experts recommend installing a separate check valve for ventilation at the air duct outlet. How to install it and other components will become clear after studying the project as a whole. You will have to take into account the architectural features of the building, other important nuances. For example, the manufacturer fan can equip his equipment with such a device in the basic configuration, so no additional funds are needed.

Conclusions and additional recommendations

When solving typical tasks, you can purchase a check valve for ventilation in the store.But the simplest designs of this type are not too complicated for self-production. The latter option makes it easier to make individual adjustments to the project.

The following tips will also come in handy in practice:

- Convenient access to the product will facilitate the performance of mandatory routine maintenance.

- Mounting on "liquid nails" complicates dismantling. It is much more convenient to use self-tapping screws, which are used repeatedly without significant damage to the strength of the fasteners.

- When choosing an installation site, consider the year-round operating cycle. Too close placement to the exit provokes icing, loss of performance.

The application of the above recommendations in a complex will help to implement a project of any level of complexity without unnecessary costs and errors.

Video:hood and non-return valve, operating principle and installation