Electric reciprocating saws: technical characteristics, advantages and disadvantages, models and rating of the best brands

The variety of power tools that builders use today is enormous. But there are among them the so-called universal devices, with which you can carry out one operation, but at the same time on different materials. This directly applies to the reciprocating saw, which can be used to cut wood, concrete, metal, plastic, glass and more, simply by changing the blade. Therefore, in this article we will understand what an electric reciprocating saw is. Consider its technical characteristics, models that are produced by domestic and foreign manufacturers.

The content of the article

- 1 What is a reciprocating saw

- 2 What is a reciprocating saw for?

- 3 Technical characteristics of reciprocating saws: wire and cordless

- 4 Cordless reciprocating saws

- 5 Reciprocating saw blades

- 6 Which is the best to buy an electric reciprocating saw

- 7 Reciprocating saws review and comparison

- 8 Rating of the best reciprocating saws

- 9 Reciprocating saws repair

- 10 Conclusion on the topic

What is a reciprocating saw

Outwardly, this device is a long tool with a pistol grip, at the end of which there is a working blade. The body has a trigger and several switches. In fact, the design of the device is simple, and anyone can understand its work.

In fact, this is an ordinary electric shovel, and its principle of operation is exactly the same as that of jigsaw... Although the latter is a descendant of an electric saw, because they began to produce it 20-25 years later. It turns out that the blade makes a reciprocating motion, thereby choosing the material to be cut by the teeth.When the tool was improved, that is, they began to use a pendulum stroke in it, it became a revolutionary invention, because the cutting efficiency of the reciprocating saw greatly increased. This characteristic will be discussed separately.

What is a reciprocating saw for?

Skeptics assure that the reciprocating saw can be replaced with other tools, at least the same grinder. It makes no sense to argue with them, you just need to indicate that the convenient oblong shape of the instrument, plus its continuation - the canvas, make it possible to use this device in the most inaccessible places. For example, if you need to cut a pipe sticking out of a wall or foundation exactly along the plane of the building structure. No cutting power tool can handle this except a reciprocating saw.

It is a great tool for pruning trees. There are practically no restrictions on the thickness of the trunk, the main thing is to know how to cut correctly. Today, many landscape designers choose saber saws to create garden and park architecture, as the most convenient in their segment.

This tool can be used to cut slab and sheet building materials, creating the required structures from them. The high maneuverability of the device allows you to bend the web, cut bends, chamfers, curved parts, and more. We add that today more and more builders choose this tool when solving dismantling tasks. It can be used to cut almost any structure. Especially indicative is the fact that logs into which steel nails are hammered are sawn with a saber. It easily cuts through both wood and steel.

If we talk about additional positive characteristics, then we note:

- dust-free saw operation;

- sparks do not jump out when cutting metals, scale and smudges are not formed on the cut edges;

- cut workpieces do not overheat;

- high safety factor;

- unpretentiousness in work;

- long term operation.

Technical characteristics of reciprocating saws: wire and cordless

Like all power tools, the reciprocating saw is divided into two main groups: household and professional. The first ones cannot be called low quality, they are simply equipped for non-intensive work. That is, it is necessary to operate these models taking into account the time it takes for them to heat up, therefore these devices require rest.

Household sabers are well equipped, their functionality is almost exactly the same as that of professional tools, they just do not have such a large operational resource. And he is not required at home. But "household workers" are several times cheaper than "professionals".

Tool power

This is the most important technical characteristic. Here the ratio is as follows: the more powerful the saw, the higher its performance. But there is also a downside: the weight of the unit increases, its size and price. Power characteristics range from 0.5 to 1.5 kW. But experts offer, so to speak, the golden mean, which has passed the test of time - from 0.9 to 1.2 kW. Such saws are convenient in terms of light weight and size, but with a fairly high performance.

Other parameters of the saw depend on the power characteristics: cutting speed and length of the tooling stroke. That is, we can say with confidence that a more powerful model will cut a large structure faster, provide the best cutting depth in the hardest material. This is what the manufacturers indicate in the product passport. It is on them that you need to pay attention when choosing a reciprocating saw. Here are the specs recommended by experts:

- file travel amplitude: 19-32 mm;

- frequency of movement or stroke length of the rig: 2500-3000 strokes / min;

- cutting depth: 220-255 mm.

The last parameter is very important. The indicated range allows the saw to be used for many types of work. And here the task is set for cutting wood, metal, and concrete. And when they talk about a tool - this is a reciprocating saw for metal, the interpretation of the purpose is wrong. Any saw can cut any material. The main thing is to choose the right file. Returning to the depth of cut, add as an example cutting trees in the garden... For this, there is no need to purchase a saw with a large depth indicator, here a parameter in the range of 19-25 mm will be sufficient.

Speed controller

Everyone knows that it is necessary to cut materials of different structure at different speeds. Therefore, manufacturers of reciprocating saws supply tools with different speeds of the hacksaw. But in different models it is implemented differently:

- The first option is the trigger itself, which is pressed with a finger to make the saw work. The harder you press it, the more the instrument “gasps”. This design is called stepless.

- The second option is a wheel or slider. By setting them in a certain position, the speed of movement of the working body is set. In this case, there is no dependence of the trigger on the speed. This design makes it possible to more accurately set the speed of the saber.

Pendulum stroke

The essence of this option is that during the return stroke, the hacksaw deviates from the cutting line. That is why the file does not heat up so much, it cleans the cut area from sawdust with its movement. This increases the cutting speed.

Attention! Not all reciprocating saws are equipped with a pendulum motion, moreover, it is not always necessary. For example, to cut along a curve, this option must be disabled.

Brand manufacturers make the pendulum stroke adjustable in their tools. This increases the efficiency of the saw when cutting materials of different structure. The denser the material to be cut, the greater the span of the blade.

Support shoe

This structural element of the reciprocating saw is a conventional stop, which abuts the tool against the cutting plane. Thus, a tight abutment of the saw to the material being cut is created, which increases the quality of the cut. Not all models have swivel shoes. And this is an improved design that allows you to cut along a curved line with a stop. At the same time, the fixation of the swivel shoe allows you to cut in any inclined plane, plus from the bottom up. It should be added that this structural addition helps to rationally use the resource of the hacksaw, especially if it has a multifunctional purpose. That is, the blade has several differently shaped teeth used to cut different materials.

Hacksaw (blade) replacement mechanism

Many manufacturers have not produced reciprocating saws for a long time, in which the blade is changed (inserted or pulled out) using a special tool. Now the change of the file is done either with the help of a lock in the form of a lever, or with a retaining ring. But these models have one drawback - you can pull out the file only if the cartridge is in the extended position.If work is stopped and the chuck remains inside the protective cover, the saw will have to be turned on again to push the chuck out. It is impossible to pull out the cartridge with your hands by pulling it by the file.

This is how the file is removed or installed into the chuck of the reciprocating saw using the retainer

When changing the hacksaw, it is recommended to check it for any looseness. If this defect is present, then you should know - this is a decrease in the quality of the cut and the durability of the tool. We add that today many manufacturers offer chucks in which the blade can be installed with the teeth up. And if you choose a reciprocating saw according to this indicator, then the choice should be stopped on just such a model.

Safety clutch

This structural element of the reciprocating saw has one important purpose - to keep the tool intact and to protect a person from injury. The fact is that if the saw blade gets stuck in the process of cutting any material, then the tool will kick back. So the clutch will not let this happen. Unfortunately, it should be noted that not all models offered on the market have this element.

Overloads and protection against them

Our compatriots are accustomed to the fact that any tool should be used to the maximum. Power tools in this regard are more delicate devices than mechanical ones, because their design is based on an electric motor. If you overload it, it will quickly burn out. And repairs are expensive. Therefore, many manufacturers install overload protection, which simply cuts off the power to the saw if the latter has exceeded the level set by the manufacturer. A very useful option.

Other useful devices

Consider what else you need to pay attention to when choosing a reciprocating saw:

- Smooth start usually mounted on heavy duty saws. Its main purpose is a break-free start of work and protection of the supply network from overload.

- Brake. Basically, this is a quick stop of the saw as soon as you stop pressing the trigger. The convenience lies in the fact that there is no need to wait for the blade to stop moving, if, for example, it is necessary to replace the blade.

- Trigger lock. There are two functional components: the first is the trigger, after pressing which, electricity is supplied to the saw motor, the second is the locking of the trigger in a certain position. The second position creates the convenience of using the power tool.

- Double insulation. This is a requirement of European standards, but it should be noted that this is not only the safety of the device, it is also an increase in its service life. Plus, such a tool can be used outdoors in wet weather.

- Vibration damping. In household appliances, elastic pads are installed on the handle and gearbox from tool vibration. A counterweight is installed in the design of professional models, which dampens not only vibration, but also noise. That is, only professional reciprocating saws have a vibration damping system.

- Housing insulation. Here you need to understand that rubber gaskets are installed everywhere between the parts of the instrument case, which protect the inside of the instrument from dirt, dust and water. But from electric shock, if the body is punctured, they will not save the operator. Therefore, a rubber "shirt" is installed over the plastic case. It is she who protects a person from electric shock.

- Brushes. These elements have one drawback - they wear out to metal fasteners, which disables the conductive element. A new approach to eliminating this problem is the brushes that stop working if they wear out to a certain level, which leaves the conductive plane of the rotating shaft intact.

- Power cable. For many, this is not the most important selection criterion, but it is he who gives freedom of action. Therefore, many manufacturers make the cable length 4 m. There is another approach, for example, a Bosch reciprocating saw - its design uses a wire with a swivel entry, which prevents the cable from bending at the point of abutment to the tool body.

Cordless reciprocating saws

A little more needs to be said about battery types. Note that such saws have always been lower in technical characteristics than network counterparts. But today manufacturers are focusing on the production of cordless tools. They are simply more convenient to use and do not depend on the location of the outlet. Therefore, modern cordless saws are not inferior in performance to network saws, the battery life has increased significantly, the latter are quickly charged (usually no more than 1 hour). Such saws have become much lighter, their price has decreased, so more and more often in the hands of builders you can see saber saws without wires.

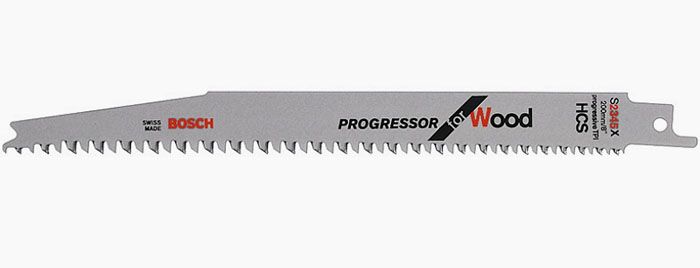

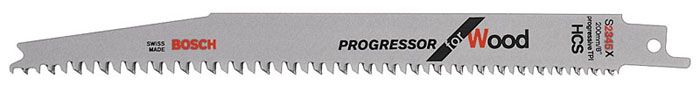

Reciprocating saw blades

Reciprocating saw blades are a hacksaw with teeth on one side sharpened at a certain angle. They are made from high-strength steel alloys and various types of durable metals. All reciprocating saw blades are marked, and by the brand you can always determine for what needs the blade can be used. We list the main brands of files:

- HCS. This type is used for cutting not the most durable materials: wood, plastic, rubber and others. Made from high carbon steel. Their length does not exceed 40 cm. It is very important to choose the right hacksaw according to the location of the teeth. Most often they are located along the canvas at the same distance. But if there is a need, for example, to saw boards in which nails can get caught, then a canvas with a variable pitch is used.

- HSS. These saws are used when it is necessary to cut sheet metal or profile, as well as any shape and size of an aluminum workpiece. Manufacturing material - tool steel. The length of such canvases varies within 30 cm.

- BIM. These canvases have the combined properties of the previous two. Therefore, they can be used both for cutting hard materials and soft materials. For example, if the conversation is about a saw for aerated concrete, then just such blades should be used in it.

- HM / CT. These files are made from hard steel alloys. They are the most durable and expensive. They can be used to cut metal, concrete, fiberglass and other durable materials. Their length varies between 75-150 mm. The photo below shows a Bosch reciprocating saw blade.

How to choose the right blade by teeth

Before you buy a blade for a reciprocating saw, you need to pay attention to the following parameters regarding the size, shape and method of sharpening the teeth. Let's make a reservation right away that along with the power of the electric motor, it is the teeth that affect the performance and quality of the cut of the power tool:

- The larger the teeth, the faster they cut the material. But the quality of the cut leaves much to be desired. Conversely, the smaller the teeth, the longer it will take to cut.

- Manufacturers produce blades with ground and milled teeth. The former are used for cutting soft materials, the latter for hard materials.

It is also necessary to indicate the method of fastening the saw itself in the saw chuck. Usually, the parameters and shape are unified, so the files are suitable for almost all chuck models. We only add that the blade shank can have different shapes: T-shaped, U-shaped, F - standard. All this is necessarily indicated in the marking. For example, T144DF is BIM.Here "T" is the shank type, 144 is the blade length in mm, "D" is the largest tooth size, where the gradation occurs in ascending order from A to D, and "F" is the designation that the tool tip is made from bimetal.

Which is the best to buy an electric reciprocating saw

It is clear that all of the above selection criteria determine the need to purchase one or another type of electric hacker. But we must understand that any reciprocating saw is determined by the blade installed on it. For example, inserted "HCS" - saw only wood or plastic.

Electric wood chopper

So, we immediately make a reservation that there is no electric saw for metal separately, but for wood separately. Therefore, we will be based on the choice of the canvas. As for the canvases on wood, then it is necessary to designate three standard sizes of hacksaws, depending on the size and shape of the teeth:

- With coarse teeth, which are used for sawing logs, thick beams and trees. They have a pitch between the teeth - 4-8 mm. The number of teeth per inch is in the range of 3-6.

- With averages. They are used for cutting medium-sized parts. They have a distance between the teeth - 3-3.5 mm.

- With smallwith a pitch of only 2.5 mm. It is clear what these canvases can be used for.

There is one more point regarding the angle of inclination of the teeth. There is a blade with straight teeth, and there is an inclined blade. The first is used for cross-cutting, the second - only for longitudinal. Prices of electric woodcutters vary depending on the power of the electric motor and the number of optional functions. The more the latter, the more expensive the device.

Electrohack for metal

Here we will not describe what are the differences between the canvases, because they have all the same positions as the saws for wood. Just different spacing between the teeth. So there is a strict rule, which states that the distance between the teeth of the cutting blades should not be greater than the thickness of the metal. This should be taken as the basis of the choice. We add that manufacturers on the packaging must indicate how thick the metal can be cut with the file you choose.

Power selection of electric saws for wood, metal, concrete and other materials

As mentioned above, all reciprocating saws can be divided into two main categories: household and professional. The first ones are used in summer cottages or suburban areas for pruning trees, dismantling wooden building structures, laying steel, cast iron and plastic pipes, if they need to be trimmed to the required dimensions. Rarely are they used to cut large concrete structures, although this is not a problem. It's just that this process will be long. Therefore, the power of household sabers does not exceed 800 W.

As for professional tools, here the power is also higher - up to 1.2 kW, and the operating resource is rather big. In any case, these tools can cut thick workpieces without stopping to rest in order to cool the electric motor.

Reciprocating saws review and comparison

We will consider well-known manufacturers who offer high-quality goods. Their names are on everyone's lips, the quality of the offered power tools is excellent, but the price is not the lowest, judging by the options offered.

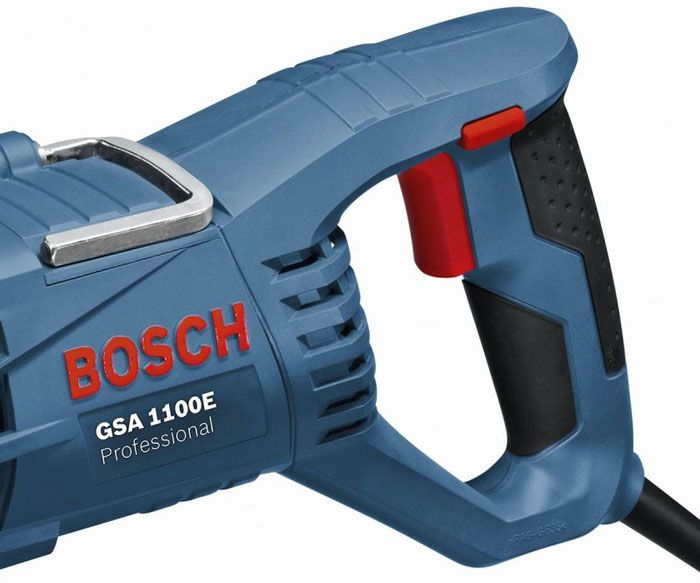

Reciprocating saws from Bosch

A well-known German manufacturer offers a fairly huge range of models of cordless and cordless reciprocating saws. There is no point in talking about the high quality of Bosch products, this is a well-known fact. We add on our own that in all forums about Bosch sabers they speak only in a delightful manner. Of course, these are not the cheapest tools, but you can overpay for such quality.

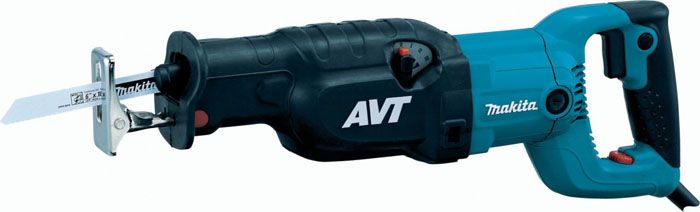

Reciprocating saws from Makita

A tool from a Japanese manufacturer is, first of all, high quality. According to experts, Makita is a universal reciprocating saw that can be used with blades for various purposes. At the same time, some models boast the ability to rotate the file 180 °, providing a cut from the bottom up. The canvas itself is fixed in the cartridge with a retainer. The power tool is equipped with electronics, which automatically monitors the cutting depth, controls the load and the speed of the working body.

Reciprocating saws Interskol

These are products of a domestic manufacturer, which in their characteristics will not be inferior to the best foreign ones, and in terms of price, they are much lower. At the same time, all models of Interskola saws are provided with full optional functionality, which indicates that these electric shovels are modern power tools of their class. The company offers both household and professional appliances. Therefore, there is a choice in this direction.

Rating of the best reciprocating saws

Let's start the rating of saber saws by dividing them into two groups: mains and cordless. First of all, we will analyze the battery, or rather, which of the models offered by the market are most in demand today. This takes into account the opinion of not only specialists, but also consumers.

Rating of the best cordless reciprocating saws

Rating of the best networked low-power reciprocating saws

Rating of the best networked powerful reciprocating saws

We must pay tribute to other models, which in many respects are not inferior to those described in the table. Of course, well-known brands will always be in demand by both professionals and home craftsmen. Everyone wants to have a good quality tool at hand. But, for example, reciprocating saws from the PIT company are no worse than Makita or Bosch.

Reciprocating saws repair

What can you say specifically about the repair of a reciprocating saw? If you are not a specialist in this matter, then you should not open and disassemble the tool. Take it to the service center, where the professionals will do it. The only thing you can do with your own hands is to change the canvas if it breaks from the load.

The main reason why the saw stops working:

- burned out electric motor;

- the graphite brushes are worn out.

The first one cannot be repaired. It is changed to a new one. The latter also change, but this is a simpler operation, which includes disassembling the saw body, removing old brushes and installing new ones. The brushes are inserted into special grooves, inside which they are pressed against the conductive plane of the spring. Each brush has a shank in the form of a stranded copper wire, it is connected to the electrical part of the device with a regular screw. Therefore, replacing brushes is straightforward.

Related article:

Chainsaw: which brand to choose. It is difficult to imagine life in a summer cottage without working with wood. In this case, a chainsaw is an important tool. So which model is right for you according to your goals and budget?

Conclusion on the topic

As you can see from the tables, this power tool is not cheap. Therefore, not everyone can afford to buy it, especially the professional model. We recommend using the service of renting reciprocating saws, which is very popular and affordable today. The only thing that must be done when renting a reciprocating saw is to select exactly the right blade for the material being cut: aerated concrete, wood, metal, plastic, etc.