How to protect your site with a chain-link fence

Ownership in any case must be protected and delimited. A chain-link fence is the most affordable and simple option. Yes, more often it is not as presentable as a fence made of bricks or polycarbonate, but practical, convenient and not very time consuming. The homemaster.techinfolux.com/en/ editorial staff will tell you how to choose materials, calculate their quantity, and install a fence.

The content of the article

- 1 A few words about the technical characteristics of the chain-link mesh

- 2 The nuances of choosing a material for a fence

- 3 We are trying to calculate how much material is needed to make a fence

- 4 How is the installation of support pillars for the manufacture of a fence from a chain-link mesh

- 5 How to install a mesh-netting for fences of different types on the posts

- 6 Is it possible to decorate a chain-link fence

A few words about the technical characteristics of the chain-link mesh

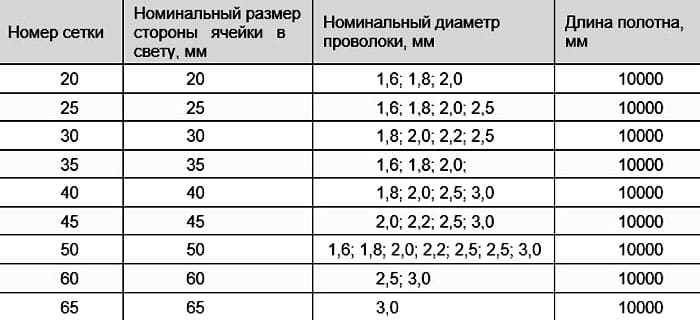

Whichever manufacturer produces a chain-link, it operates within the framework of GOST 5336-80. There are several types of such fencing.

As for the material of manufacture, they take low carbon steel for ductility and stainless steel for rigidity. Outside, the product is covered with a protective material.

Manufacturers indicate the thickness of the coating in g / m². The galvanized version can show the amount of zinc in the range of 10-90 g / m². The more zinc, the longer the service life of the mesh.

Non-galvanized products are quite cheap, and corrosion is willingly arranged on such fences. Everything is fencing will last about 10 years, although for a low-aggressive environment, the period increases.

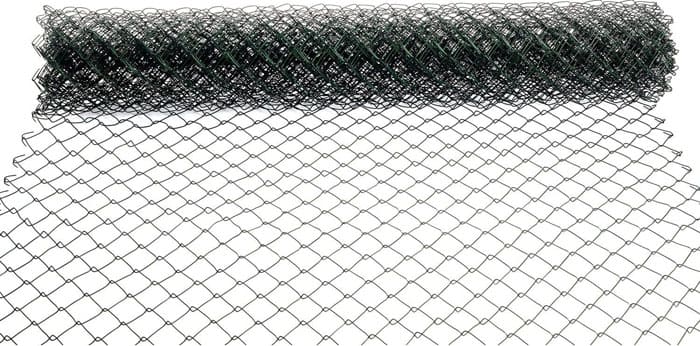

The polymer coating allows the mesh to be used in more difficult conditions. They produce products in different colors.

Related article:

Fences and barriers for the house. Photo ideas and original solutions with advantages and disadvantages in a separate publication of our portal.

The nuances of choosing a material for a fence

When choosing a future fence, they take into account not only the material of manufacture, but also the shape of the cells, the types of pillars and their height.

As for the choice of mesh-netting

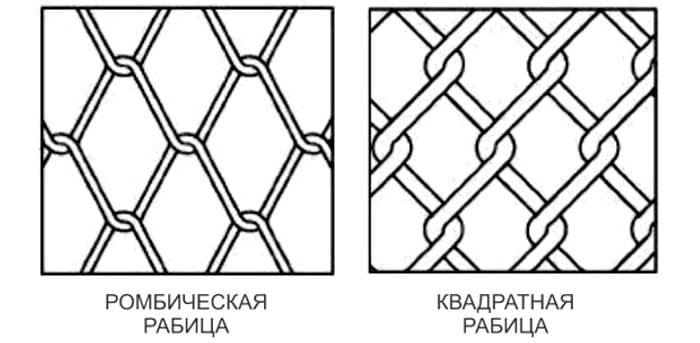

Cells can be diamond-shaped and square. For rhomboids, the angle is 60º.

The size of the cells is also variable. The clearance for a rhombic mesh is 5-10 mm, and for a square mesh 25-100 mm. The diameter of the wire also plays a role in the strength of the fence and can be equal to 1.2-6 mm.

GOST indicates that a mesh with cells of 10 × 10 mm² should consist of wire with a diameter of 1.4-1.6 mm. The larger the clearance, the thicker the wire, but the smaller the cell, the stronger the fence.

Usually the mesh is produced in rolls of 10 or 15 m with a width of 1000 or 1500 mm. Manufacturers don't mind making custom-made products.

The marking will tell you the necessary information about the dimensions: 50 × 50 × 2 (1500 × 10000) can be easily translated as a clearance with a width of 50 mm, the wire thickness is 2 mm, the roll is 1500 mm in width and 10000 mm in length.

The cells must be even, the ends of the spiral are bent towards the base, and the spiral itself must not have gaps in the turns.

How to choose poles

The material from which the pillars are made can also be selected to your taste. A choice of wood, metal, concrete, asbestos cement.

The cheapest option would be wood pillars. Supports with a round diameter of 15 cm, or a square section of 15 × 15 cm² are best suited for the fence.

For the pillar to last longer, the part that is in the soil must be covered with heated resin. There are also other formulations for handling support. Part above the ground is covered with linseed oil and varnish

Concrete poles are much more durable, while there is no need to buy special poles, any suitable option is suitable.

Metal supports can be made of shaped or round pipes. This is the longest-lasting fencing option that does not require regular repairs. You can buy even the best option - polymer-coated profile pipes.

The rarest option is asbestos-cement posts.

The service life is not as high as that of metal, but the weight of the mesh will be much less than that of other types.

Related article:

Fences for private houses: photo ideas. In a separate publication, original ideas and examples of fences made of different materials for every taste are presented.

We are trying to calculate how much material is needed to make a fence

There are several ways to assemble a mesh fence, and each assumes a different amount of material.

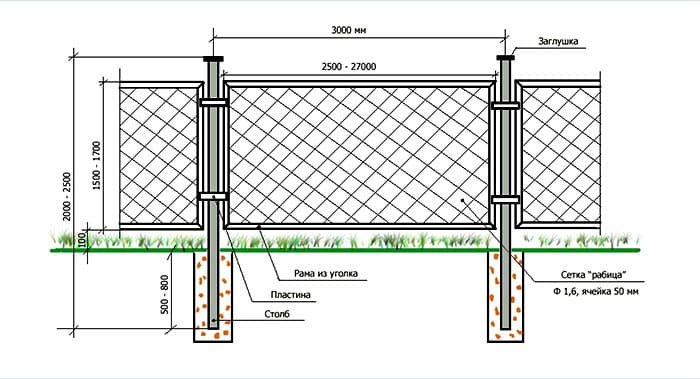

The standard height of the chain-link fence is 1-2 m, and the distance between the posts is kept at 2.5 m.

In order not to be mistaken in calculating the height, the distance between the ground and the lower edge of the grid is calculated, this is about 5-10 cm, plus the height of the section itself. From the edge of the grid to the edge of the support there will be about 20 cm more. Do not forget that this also includes the underground part. The pillar is deepened into the ground by 50-70 cm.

The number of posts will tell you the total length of the fence with a distance of 2.5 meters between the supports

To find out how many running meters of the chain-link you need to purchase, they will find out the exact size of the site that needs to be protected.

The tension wire can also be calculated: its length will be two lengths of the fence. If the tension should be in the middle, then you need to take three.

How is the installation of support pillars for the manufacture of a fence from a chain-link mesh

Special preparation of the site is not required, it is not even necessary to uproot the plants that will grow near the fence.

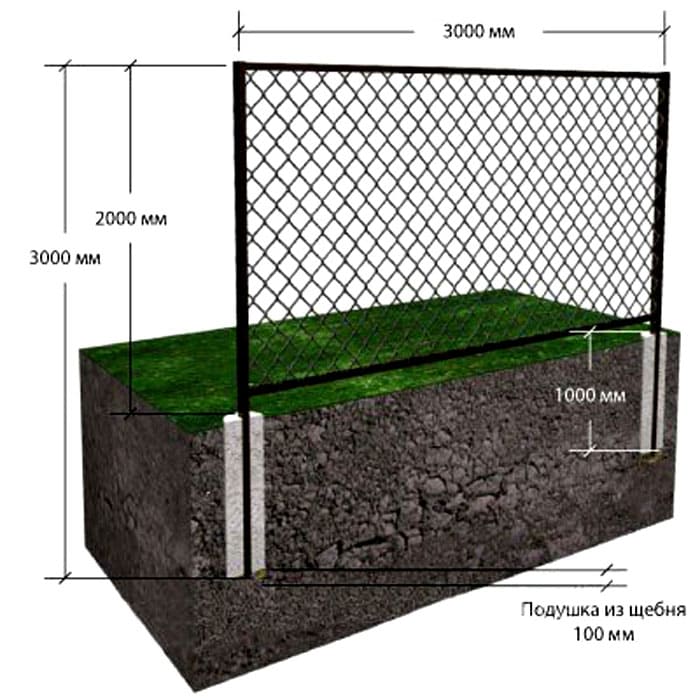

It is not necessary to pour a concrete foundation, it will be enough to immerse the post in a prepared hole and fill it with a cement solution

If the bar is wooden, it is treated with an antiseptic compound, and the metal is cleaned of rust and covered with an anti-corrosion agent.

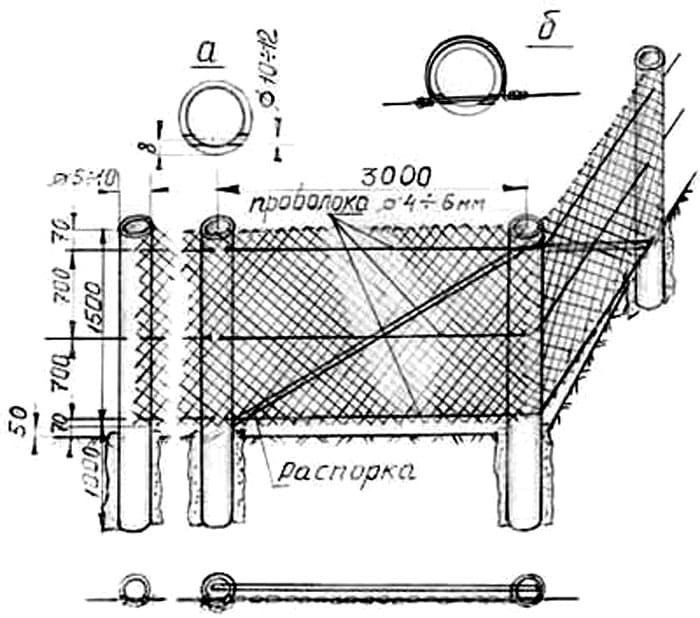

Due to the fact that the mesh is still weighty, it is better to set the supports deeper. The minimum depth is 50 cm, the optimum is 1 m. The corner supports are installed first, which should be reinforced with spacers: they will prevent the slope.

If there are no spacers, thick-walled posts are installed.

A rope is pulled between the corner posts, the places of the gates and wickets, as well as all the supports, are marked.

There are two ways to install supports:

- The posts are driven or screwed in to the desired depth. In this case, it is difficult to maintain the same level and you can inadvertently damage the pipe.

- First, they dig or drill a hole for the post. The depth of soil freezing is taken into account. The pillar is inserted and concrete is poured around.

If the soil is not solid, but loose or heaving, then you can deepen the pillar another 20 cm below the level of soil freezing. In an extreme case, the soil around the pipe is replaced, the space around is filled with 40 cm of crushed stone, and the post is filled with concrete.

Advice! The motor-drill will drill equal holes, it remains only to work a little with a sledgehammer.

How to install a mesh-netting for fences of different types on the posts

You can make a simple stretch fence, a guyed fence, a lagged fence, and a sectional fence.

Simple stretch fence

For this type of installation, you will need a guide wire. It will ensure proper tension between the supports. You will need a lanyard, a tensioner and a hook with a long thread. From additional equipment, brackets, clamps, bays and clamps are used.

First, the mesh is tied from one edge to the corner post, and the second edge is pulled. If the mesh sags, use intermediate fasteners.

It is not necessary to stretch the wire through the mesh cells. If the section of the fence is tiny, then this is still permissible. With a long fence, it's pointless

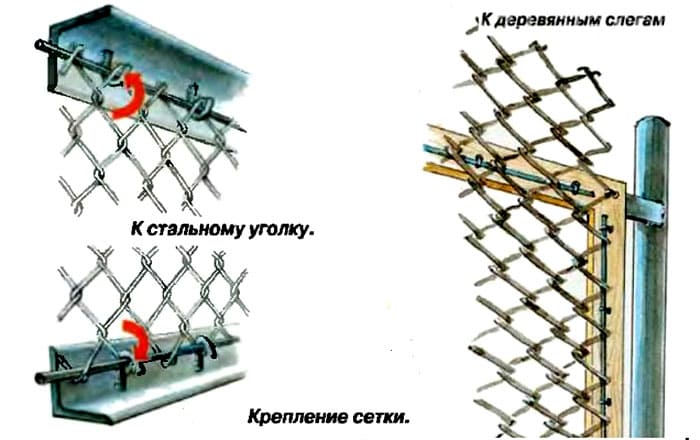

The mesh is attached to the reinforcement so that the folded edges point up.

Video: attaching mesh to reinforcement

Guarded fence

The higher the stiffness of the fence, the better. In order for the structure to successfully withstand the wind and not sag, wire stretchers can be used.

First you need to pull the strings, and then mount the chain-link, tying it to the guy wires using galvanized knitting wire (a suitable section of 1-1.5 mm).

Fence with logs

To make the supporting frame stronger, logs are welded to it. A profile pipe is ideal as a lag. If you use this method, there is no need for corner braces.

The canvas of the chain-link is screwed onto the frame with wire. This is the best way to mount the mesh for subsequent decoration or, if there are plans, replacing the netting with a metal profile or slate.

Sectional fence

To get such a fence, you need to make a number of sections and make a frame.

How to assemble a frame

You need a metal corner to work. The frame is calculated as follows: the height is equated to the length of the support and subtract 100-150 mm, and the width corresponds to the distance between the two posts.

First, a corner is dissolved with a grinder, and the resulting blanks are welded into a frame. Unwind from the net roll as much as necessary, and separate it by twisting the wire. Then in 4 directions you need to start the reinforcement, which will allow you to pull the chain-link to the edge of the corner.

The reinforcement bar should be welded along the edge of the frame from the inside of the corner.

The second option for installing the mesh is to weld on 3 mm hooks from the inside of the corner.

After that, the edges of the hooks are welded into a loop.

Installation of sections

When the sections themselves are ready, they can begin to be mounted to the profile support pipes. To do this, a metal die (6 × 60 × 250 mm) is welded onto the pipe, and the section is already welded onto the die or the frame is fixed with bolts.

The gap between the support and the section should be 40-80 mm.

Installation itself is simple, but the manufacture of sections for many is a big problem. These are size errors, and the difficulty in installing the mesh without sagging, and someone does not know how to work with a welding machine.

Is it possible to decorate a chain-link fence

If at the word "chain-link" you imagine a boring perforated fence made of braided wire in your imagination, then we hasten to dispel your boredom. The mesh fence is beautifully decorated if you approach this issue with imagination and the desire to decorate your site, making it unique.

An openwork fence is obtained by interweaving fine wire or woolen threads. But the second option is only suitable for a year or two, then the threads will fall apart

We hope that you will not have any difficulties installing the fence. You can definitely make your fence strong and beautiful!