LVL bar: what it is and the scope of its use

New technologies are widely introduced into various spheres of production and sometimes an uninitiated person simply does not know about the appearance of new goods and products. This applies to almost all areas, including the construction industry, where everything seems to have been known and tested for a long time. LVL timber, what is it - the scope of use, properties and performance characteristics, advantages and disadvantages, as well as an overview of leading manufacturers and prices for their products, this is the topic of this article by the homemaster.techinfolux.com/en/ editorial office.

The content of the article

- 1 LVL timber: where innovative material is used

- 2 Properties and characteristics of glued laminated timber LVL

- 3 Should you buy: exploring the pros and cons

- 4 Manufacturing process

- 5 Leading manufacturers of LVL timber

- 6 LVL-bar of the Ultralam trademark (Ultralam)

- 7 Areas of use of LVL-bar: studying the issue

- 8 Review of prices for products of domestic manufacturers

- 9 Video: Ultralam ™ LVL Bar Advantages and Disadvantages

LVL timber: where innovative material is used

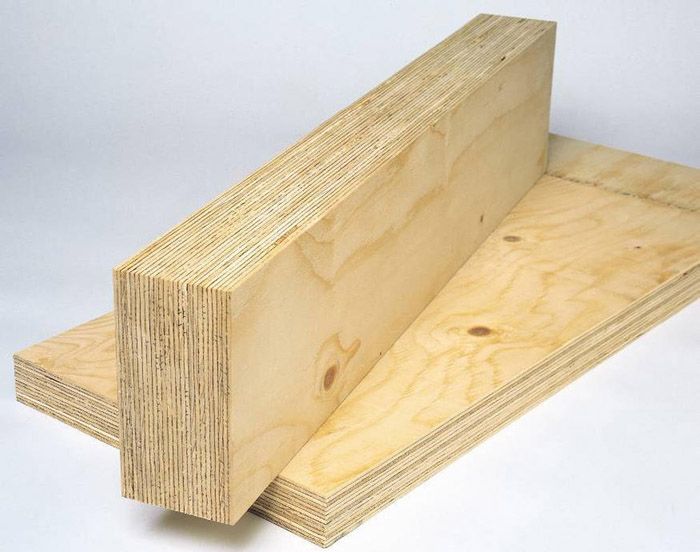

LVL timber is a building material made from coniferous wood by peeling the raw material with subsequent gluing of the resulting veneer under external mechanical pressure.

Important! The raw materials for the production of LVL-bar are selected during its procurement, which allows to reduce the percentage of waste in the manufacture and ensure the quality of the resulting products.

The thickness of the peeled veneer used in the manufacture of products is 3.0 mm, and the thickness of the final product depends on the number of layers and varies from 18 to 102 mm.

Note! In the manufacture of timber, veneer is laid in such a way that in layers located next to each other, the fibers are parallel to each other.

LVL beams are produced in various standard sizes, which expands the possibilities of their use in construction

This technology is used to produce not only barbut also sheets, respectively, the width of the products obtained is from 100 to 1800 mm, and the length, in accordance with the standard, is up to 18.0 meters.

Properties and characteristics of glued laminated timber LVL

Initially, this material was intended for the construction of houses, therefore, one of the main properties that was paid attention to was the ability to withstand the loads acting on the ends of the LVL bar. For this purpose, in the manufacture of products, the fibers are arranged in parallel in adjacent rows.

Note! LVL is one of the most durable materials made from wood. Its strength is several times higher than that of a simple glued bursa.

Operational and main technical characteristics of LVL-bar are shown in the following table:

| Indicator / characteristic | The values |

|---|---|

| Bending resistance along the grain, MPa | 22,5 – 27,5 |

| Tensile strength, MPa | 16,5 – 22,5 |

| Fire resistance class | "E" |

| Density, kg / m3 | 480 |

| Humidity,% | 8-12 |

| Roughness, μm | ≤ 320 |

| Wear resistance | 4 |

| Charring rate, mm / minute | 0,7 |

| Emission class (formaldehyde) | "E1" |

Should you buy: exploring the pros and cons

LVL timber is a fairly popular building material when performing certain works and manufacturing critical structures due to its advantages, which include:

- high strength with relatively low weight;

- ability to maintain specified dimensions - not susceptible to shrinkage during use;

- excellent appearance and uniformity of the structure;

- good performance in heat preservation and sound insulation;

- long service life.

The main disadvantage of this material is its high cost, as well as the presence of formaldehyde resins used in the production process.

Manufacturing process

The production of LVL timber is a high-tech process that is similar to other technologies for the production of wooden products and board materials (glued laminated timber, MDF, plywood etc.), but has some peculiarities in comparison with them.

Initially, the raw material goes to the debarking machine, where the bark is removed from the logs harvested from coniferous trees (spruce, pine, fir), after which the prepared blanks are sawn and fed to the veneer removal machine.

Note! Rotary cut veneer is a veneer obtained on a special machine by using knives, which are inserted into the interface with a rotating workpiece (block) and cut a layer of wood of a certain thickness.

The resulting veneer in the form of a tape is cut and sent to the drying chamber, where it is dried.

After drying is complete, the veneer is tested and sorted by quality and external indicators (uniformity, roughness, etc.).

When the sorting is completed, the dried sheets are treated with an adhesive, laid in several layers in accordance with the specified dimensions, and sent to the press, where they are glued under excessive pressure and at high temperature.

Upon completion of gluing, the sheets are cut according to predefined parameters (shape, length, width, etc.) and packed.

Leading manufacturers of LVL timber

LVL timber is produced in many countries of the world, especially its production is widespread in the USA and Europe, which is associated with the popularity of frame housing in these countries.

In our country, the production of this material is present, but not as widely as other types of woodworking industries.

Similar production facilities exist in our country in the city of Torzhok, Tver region (enterprise Talion Terra) and in the city of Nyagan, Khanty-Mansiysk Autonomous Okrug of Tyumen region (enterprise LVL Yugra).

Related article:

Projects of houses from a bar for permanent residence. Interesting layouts and advantages of glued and profiled timber in a separate publication of our portal.

LVL-bar of the Ultralam trademark (Ultralam)

The Ultralam trademark belongs to the company "Modern technologies of wood processing" and under it products are manufactured at the enterprise "Talion Terra" (Torzhok).

Distinctive features of the products of this company are such indicators as:

- the production process is based on the technology of continuous pressing with microwave heating;

- the press installed at this enterprise is one of the longest, which allows producing products up to 55 meters long.

Important! The use of high-tech equipment from leading world manufacturers allows us to produce high quality LVL-timber using waste-free technology.

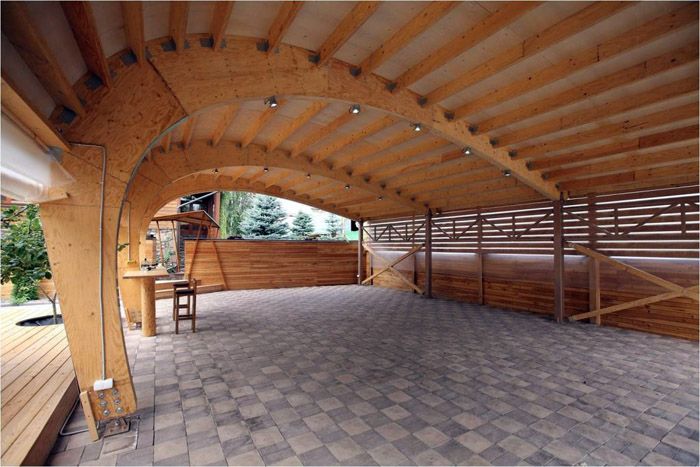

LVL timber can be simply irreplaceable in the manufacture of complex building structures of the original shape

Areas of use of LVL-bar: studying the issue

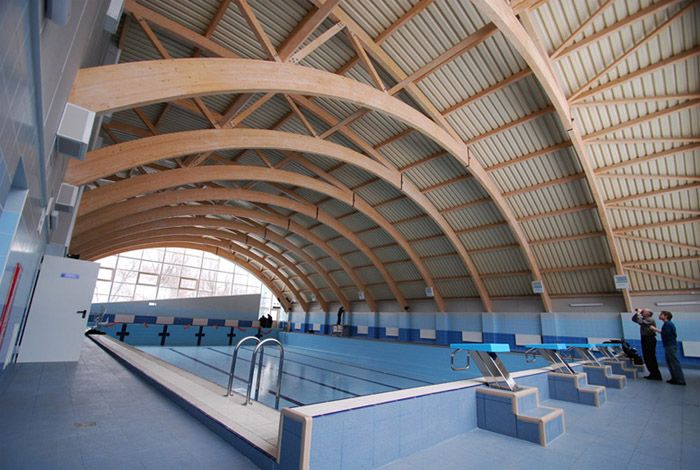

Due to its physical properties and good characteristics, LVL timber is used in the construction of houses and other structures, if necessary, to create durable building structures, such as:

- rafters and other structural elements of the roof;

- frame house building;

- bearing structures of buildings and structures of complex geometric shapes.

In addition, this material is used in the manufacture of individual elements of building structures, which are subjected to significant mechanical loads during operation, these are:

- flights of stairs and openings;

- arches and other light open structures used in the construction of summer verandas and cafes.

High strength and resistance to external influences make it possible to use LVL timber in the manufacture of complex structures operated in difficult conditions

Review of prices for products of domestic manufacturers

As it was already written above, only two companies produce LVL timber in our country, and it is for this reason, as well as in connection with the high adaptability of the process, which requires complex and energy-intensive equipment, that the cost of these products is quite high.

As of the III quarter of 2018, the cost for LVL-timber and LVL-slab, on average in the country, is 28,000 - 35,000 rubles per 1.0 m3 products.

The price depends on the quality of the raw materials used (grade, density, etc.), as well as the region where the construction site is located or the trading company selling such products.

Video: Ultralam ™ LVL Bar Advantages and Disadvantages

In order to visually assess the advantages and disadvantages of an LVL-bar, we suggest watching the following video: