How window tides can help reduce home renovation costs

To protect window structures and the exterior of a building, it is imperative to install window sills. Their second name is the external window sill. They are made of a metal or plastic profile, which is installed under the window opening on the outside of the building. The main function of the elements is to protect butt joints from precipitation and condensation. Also, the service life of the exterior finish and the window frame depends on this. In the article, we will talk about what ebb tides are, the advantages and disadvantages of each material, as well as how to install the external window sill yourself.

The content of the article

- 1 What is an ebb on a window, what is its purpose

- 2 General requirements for the geometric parameters of the ebb

- 3 General requirements for installing ebbs

- 4 What materials are ebb windows made of

- 5 The main nuances of making and installing a metal ebb with your own hands

- 6 DIY step-by-step instructions for installing a metal ebb on plastic windows

- 7 The cost of ready-made window sills and their installation

- 8 Conclusion

- 9 Video: installing a window sill on an insulated wall

What is an ebb on a window, what is its purpose

Window ebb does more than just a decorative function. He simultaneously solves several problems:

- protection against moisture ingress on the window sill and window frame;

- removal of moisture from glass;

- gives a finished look to the external design window opening.

If we neglect the installation of the ebb, moisture will collect on the windowsill, the processes of destruction of finishing materials will begin: the plaster will fall off, the window frames will become unusable. If the slopes are protected Pvc, mold and mildew will form under them.

This is the main answer to the question, what are the slopes on the windows, and why they should be installed without fail. That is why the installation of structures is performed not only for the decorative design of the opening, but also in order to prevent possible destruction of the finish and structures.

General requirements for the geometric parameters of the ebb

Before choosing an element, you should study the basic requirements and technical dimensions of the future product:

- the width of the sill depends on the width of the opening. To these dimensions, add 3-4 cm per ledge. It is also necessary to take into account the small angle of inclination of the ebb. The minimum width of the product is 90 mm;

- to measure the length, measure the distance between the edges of the window opening from the outside. Add 3-4 cm to the obtained measurements on each side. The finished product should be 6-8 cm more than the distance between the edges on the outside of the window opening;

- it is important to choose the right configuration of the finished structure. External window sill for frame house will be different from the ebb in a brick or panel building;

- the color of the ebb for windows and the basement must be combined with the external design of the window opening. For white windows, the outer sill should also be white. If the frames are made in a different color scheme, the window sill should be painted in the same color or a tone darker.

General requirements for installing ebbs

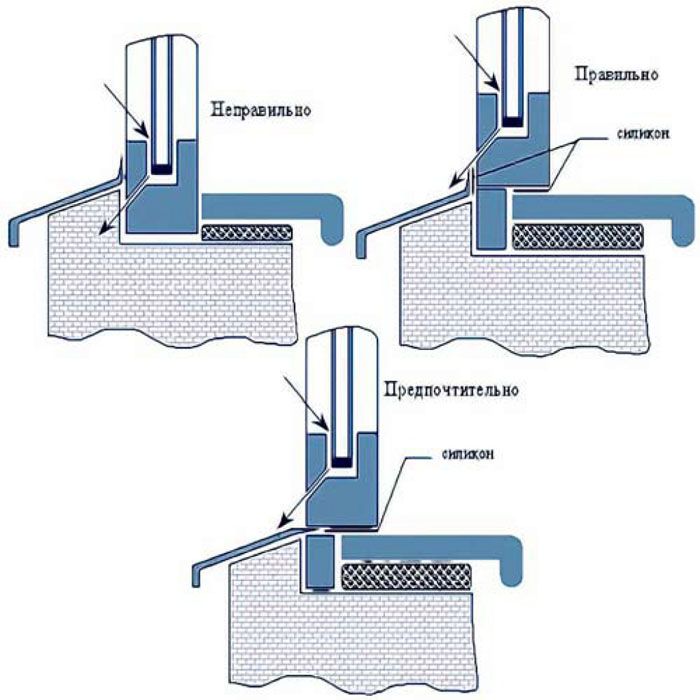

Improper installation of the external window sill will lead to its rapid wear. In addition, it will not perform its main functions, water will flow under it, which will lead to rapid deformation of window structures. When installing an ebb, it is important to observe the following requirements:

- Tight fit of all butt joints and their sealing.

- Sealing butt joints is an additional, rather than primary, measure of protection against water ingress. The service life of the sealant is short, sooner or later water will get inside.

- Compliance with the step-by-step technology of installing the ebb plastic window.

- The width of the product should be 3-4 cm larger than the window slope.

- It is important to check the horizontal line with a spirit level after installation. Rain streams should fall evenly on the windowsill, if improperly installed, they will accumulate in one place.

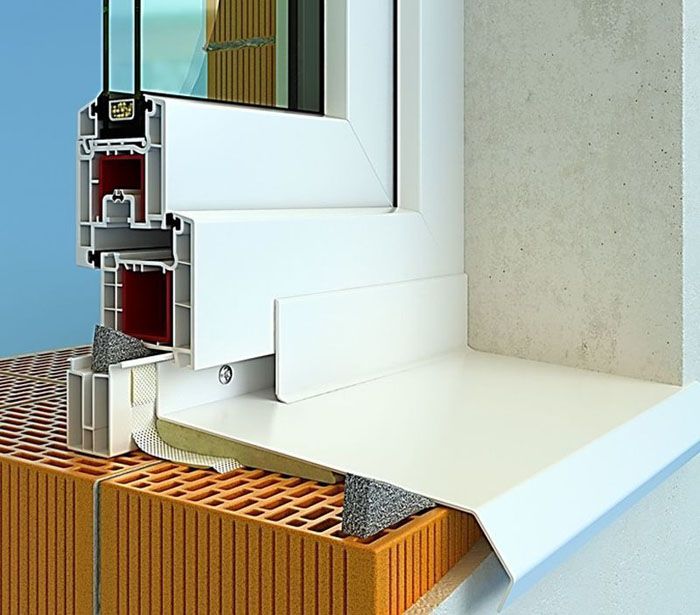

- The base under the outer window sill should be made of cement-sand mortar. It is not recommended to expose the ebb on several wedges and fill the voids with polyurethane foam, since sometimes they sometimes become feet on them when washing windows. Polyurethane foam will not withstand such loads.

- The side edges of the slopes for plastic windows must be covered with trim.

Subject to these simple rules, the ebb tide will last quite a long time. It is much easier to adhere to the correct construction technology than to subsequently repair them.

What materials are ebb windows made of

Not all materials can be used for external window sills. As a result, rust or smudges on wall surfaces can form on the ebb. It is important to figure out what is the best way to make them. Let's take a closer look at the advantages and disadvantages of all the recommended materials.

Sheet steel for external window sills

Non-galvanized sheet steel, in spite of the affordable cost of a metal sheen for plastic windows, is less and less used for the production of structures due to its increased corrosion under the influence of precipitation. This is especially noticeable in urban conditions, where the acidity of the rains is much higher. To prevent these processes, it can be coated with a special powder paint.

Over time, work will be needed to restore the coating with preliminary cleaning from rust. Alternatively, cover the outer window sill with a polymer compound. Due to this, not only will the product's life be extended, but also the noise generated by precipitation will be reduced.

Despite the negative features, metal ebbs have a number of positive properties:

- high strength;

- the ability to manufacture according to any customer size;

- various colors:

- resistance to temperature changes throughout the year.They tolerate both low and high temperatures;

- easy care;

- resistance to sunlight.

It is advisable to install metal sills with additional sound insulation.

Important to remember! The product may become very hot in summer weather.

Aluminum window sills

The strength of aluminum structures is much higher than that of metal ones. Due to this, their service life is longer. Products can be made up to 35 cm wide in brown or white. Also, coloring, if desired, can be done in any shade using powder paint. It must be said about some negative aspects of aluminum:

- high price;

- increased noise during rain, and therefore requires additional noise insulation.

Plastic external window sills

Polyvinyl chloride structures are considered the most practical. They have practically no flaws. The advantages of the material include:

- moisture resistance;

- not affected by precipitation;

- easy installation;

- easy care;

- excellent sound insulation;

- beautiful appearance.

Polyvinyl chloride is not yet widely used. It has one significant drawback - fragility. Therefore, near schools or playgrounds it is not recommended to install plastic window sills. When the ball hits, it will just crack. In addition, at low temperatures, the strength is also significantly reduced.

Installation of plastic structures is performed at a slope with high-quality processing of joints with a sealant. In climatic regions with a predominance of low temperatures, it is still worth choosing a different material.

Epoxy resin

External epoxy sills are considered heavy-duty. It contains fiberglass. You should talk about the main advantages of the material:

- corrosion resistance;

- can be both independent ebb tides and an overlay on an already mounted window sill;

- reduced noise during precipitation.

External epoxy shields are available in white, brown or black.

Polyester drips

An additional polyester overlay is installed on the galvanized outer window sill. In addition to being decorative, it has a protective function. The cover can be made of the following materials:

- polyester;

- polyurethane;

- pastisol.

The main advantages are high strength and resistance to various acidic environments. They can be colored in different colors... Ebb tides require careful handling due to the possibility of scratching. The service life of such products can reach 30 years. Therefore, today, polyester ebbs are rightfully considered the most practical.

Galvanized window sills

Galvanized castings are the most common among analogues. Most often they are made in white and brown colors, they can also be laminated under a tree. The steel thickness is about 0.55 mm, the service life reaches several decades. If the painting was done using powder paint, you need to be prepared for the fact that over time it may crack or fade.

It is important! The main nuance of galvanizing should be noted: noise during precipitation or gusty winds. The latter can occur due to improper installation.

Alloy steel is used for the production of galvanized castings, which gives the product additional strength and resistance to atmospheric precipitation. Galvanized elements are often coated with a polymer layer that protects the product from the adverse effects of acidic environments. The price of ebbs for galvanized metal windows is affordable, which is an advantage when choosing.

The main nuances of making and installing a metal ebb with your own hands

In order not to return to the repair of the external window sill after a few years, some advice from professional craftsmen should be considered:

- when marking a metal product, an allowance for slopes of at least 2 cm should be taken into account, while the edges should be folded up. This will significantly extend its service life, and also prevent the formation of condensation in the winter;

- the protruding part beyond the window sill should be at least 4-6 cm, the angle of inclination should be at least 10 °. This will allow water to drain freely from the outside window sill;

- the width of the window sill should also be 2-3 cm wider, otherwise water will get into the structure. You can pre-glue the slopes with vapor-permeable tape. It will remove excess moisture from wall surfaces. The tape needs to be brought to the slope with one edge, the other - on the cleaned windowsill;

- metal drips should enter the side wall surfaces of the facade by 4-7 cm. This will not only secure the structure, but also protect against water leaks;

- if the slopes are finished with a solution, it is necessary to embed the outer window sill into them at a distance of at least 1 cm. This will prevent the formation of leaks and preserve the outer finish;

- it is important during installation to check the levelness of the ebb with a level. This is necessary to prevent the accumulation of precipitation in one place;

- fastening to the window frame with rivets or self-tapping screws should be carried out from the middle. This will prevent its deformation and displacement. The distance between the rivets should be about 20-30 cm from each other;

- to seal butt joints, an acrylic-based silicone sealant should be chosen.

Installation of the ebb is made at a slope with a cut-in in the facade. During installation, a vapor-permeable tape was applied

DIY step-by-step instructions for installing a metal ebb on plastic windows

Installation of the structure does not cause difficulties. Before installing ebb windows on plastic windows, you should familiarize yourself with the technological process and take into account the advice of professionals. Work should start with cleaning the base. To do this, you need to remove excess foam, cut off the protrusions and clean the surface of debris.

Further, the installation sequence is as follows.

This process can be seen in the video:

Related article:

How to regulate plastic windows yourself? In a separate publication you can find detailed instructions on adjusting windows in different situations.

The cost of ready-made window sills and their installation

Before buying an external window sill, it is important to decide on the final option. For PVC windows, plastic drips are suitable. For wooden windows the ideal solution would be to install a galvanized or aluminum product. The cost of the finished version will depend on the material and dimensions. The price range is quite wide.

We suggest that you familiarize yourself with the approximate cost of materials and give approximate prices for installing ebbs on windows.

| Materials, type of work | Cost, rub. |

|---|---|

| Ebb from aluminum, rm. m | 400-500 |

| Galvanized steel with color coating, running. m | 300-400 |

| Galvanized low tide, running. m | 300 |

| PVC ebb, lin. m | 200-300 |

| Ebb installation, including preparatory work, run. m | 350-400 |

| Sealing the gaps with polyurethane foam | 250 |

| Sealing gaps with sealant | 250 |

| Cleaning gaps from polyurethane foam | 300 |

You can buy ready-made ebbs for windows with minimum dimensions at a price with installation from 2,000 rubles.

Conclusion

Window drips can be installed during the installation of window structures. But if it becomes necessary to replace the old external window sills, you should carefully study the advantages and disadvantages of each material, as well as their external compatibility with the frame and home decoration... We hope that the proposed material was useful, and you will be able to choose the structures and install them correctly, taking into account all the nuances. If you have any questions, write in the comments, we will try to answer them.

In conclusion, we suggest looking at another way to install a window sill with your own hands.