Sandwich panels: sizes and prices, as well as how to choose and carry out installation work

In recent years, there have been significant changes in the building materials market. Due to the fact that new technologies are developing, new materials have appeared that make it possible to carry out construction and installation work in a shorter time, without reducing the thermal and strength characteristics of the buildings being erected. One of these construction technologies has become frame, when the building frame is made of a metal profile, and the enclosing structures (walls, roof, partitions) are mounted using sandwich panels. What are sandwich panels, their sizes and prices, as well as how to choose and perform installation - this is the topic of this article by the homemaster.techinfolux.com/en/ editorial office.

The content of the article

- 1 Sandwich panel - what is it

- 2 Advantages and disadvantages

- 3 Classification of sandwich panels by construction

- 4 Types of sandwich panels

- 5 Leading sandwich panel manufacturers

- 6 How to choose a sandwich panel - our editorial team's recommendations

- 7 Installation of sandwich panels - the main nuances

- 8 How much do sandwich panels cost

- 9 Video: cargo service station from sandwich panels

Sandwich panel - what is it

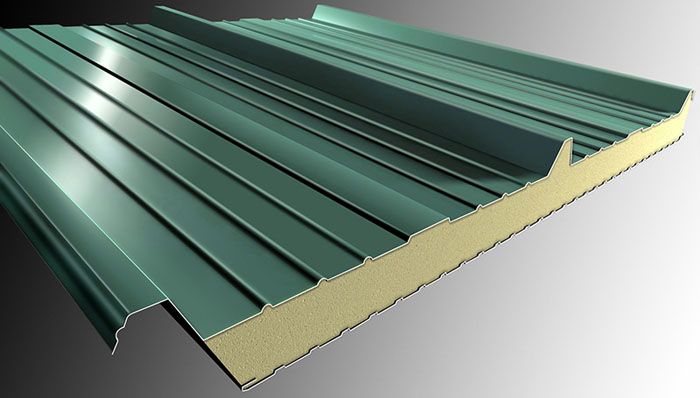

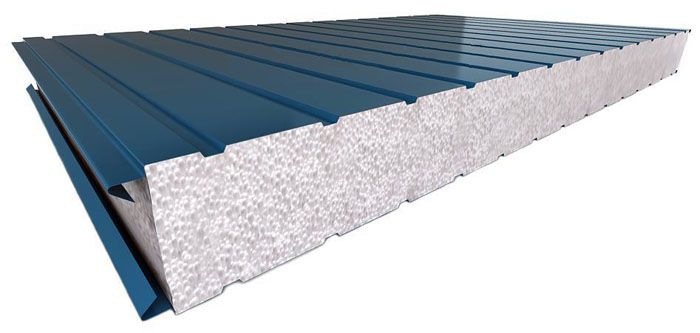

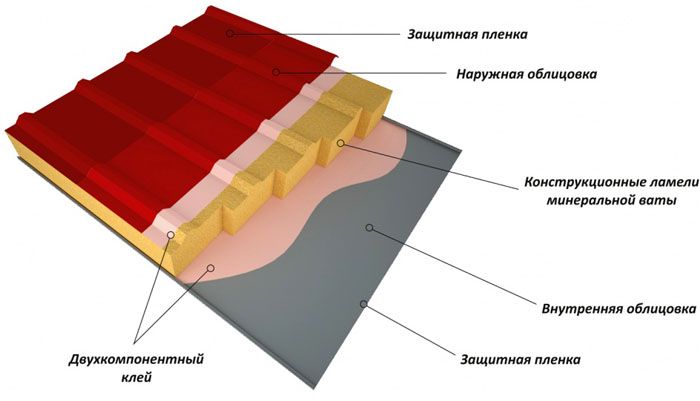

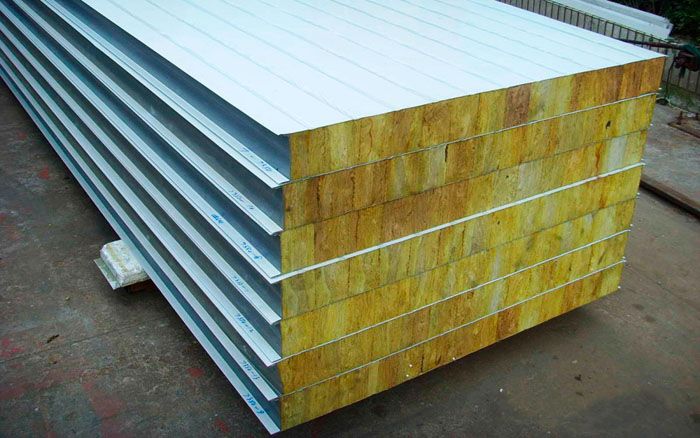

A sandwich panel is a building material that is manufactured in the factory and delivered to the construction site in finished form. Structurally, a sandwich panel looks like a three-layer sandwich (sandwich), in which two layers are made of a rigid material (metal, plastic, lumber, etc.), between which a layer of insulation is laid (mineral wool, polyurethane foam, polypropylene, etc.) ).

Depending on the materials used and the construction, sandwich panels are classified as wall and roof panels for windows and partitions, which is expressed in their thickness and profile used to form the outer layer of the product. In the manufacture of the panels, they are equipped with special locking joints, which are structural elements by means of which they are connected to each other.Wall panels can be mounted vertically or horizontally, depending on the type of their layout, corresponding to the design documentation of the facility under construction, and roofing panels - when constructing roofs of different profiles.

Advantages and disadvantages

Sandwich panels are a popular building material, especially in the construction of industrial facilities, due to their advantages, which are:

- ease of installation work that can be performed without the involvement of heavy construction equipment;

- fastening to the frame provides a low weight of the structure to be mounted, which will allow the use of light-type foundations that do not require significant capital investments;

- fast installation time, regardless of weather conditions and time of year;

- good heat engineering characteristics make it possible to build buildings using this building material even in the regions of the Far North;

- during the construction of buildings, additional processing of internal surfaces is not required, because the surface of the sandwich panel is already smooth and made in a certain color;

- a variety of modifications, differing in thickness and color solution, allows you to choose the product required for specific conditions of use.

Of the disadvantages that are inherent in this building material, it should be noted such indicators as:

- susceptibility to destruction under external mechanical influences aimed at breaking the structure and cutting;

- relatively short service life due to the type and characteristics of the insulation used;

- is a fire hazardous material, during the combustion of which harmful substances are emitted, the list of which depends on the brand of insulation used in the manufacture of the panel.

Classification of sandwich panels by construction

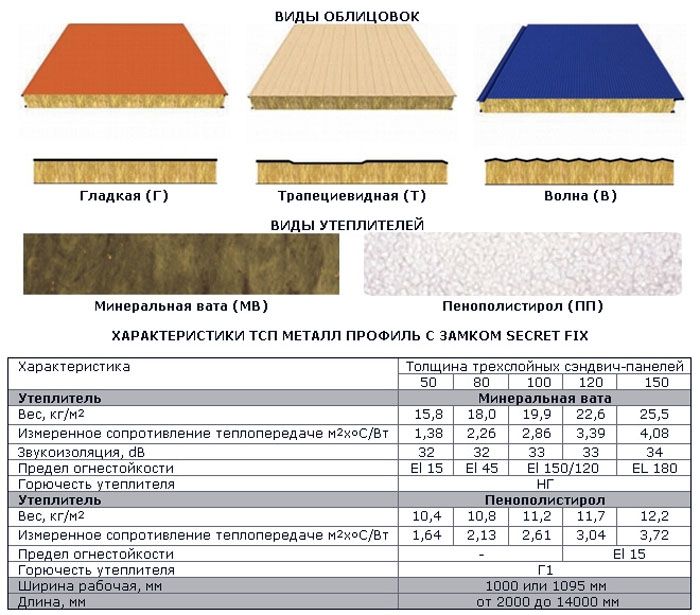

As mentioned above, a sandwich panel is a three-layer product, the design of which is shown in the following figure.

External and internal cladding

For cladding sandwich panels, creating an outer and inner layer, various materials are used, namely:

- metal - sheet galvanized or stainless steel, made in the form of a profile of various sections, depending on the purpose of the panel, with an additional protective coating;

Note! Various types of polymers (polyvinyl fluoride, plastisol, pural, polyester), as well as fabric, paper or foil are used as a protective coating applied to metal sheets used for external and internal cladding.

- board materials made from waste woodworking industries (fiberboard, particle board, plywood, etc.);

- various types of plastic (PVC and others);

- paper.

Insulation used in the manufacture

In the manufacture of sandwich panels, different types of insulation are used, which ultimately determines the thermal characteristics of the resulting product, as well as its weight and fire hazard. It can be mineral wool and fiberglass, polyurethane foam and polystyrene foam, as well as polyisocyanurate foam and a combination of these materials:

- Mineral wool. Distinctive features of this type of insulation are: incombustibility and the ability to absorb moisture. In addition, the advantages of mineral wool include such characteristics as high performance in heat and sound insulation, environmental friendliness and non-susceptibility to deformation during temperature fluctuations. Among the shortcomings, it should be noted: a decrease in thermal performance during use and significant weight, as well as increased vapor permeability and the ability to perform installation work only in the absence of precipitation.

- Fiberglass. This material is similar to mineral wool, and its advantages include: strength and resistance to chemically aggressive substances, as well as a relatively low specific gravity, and the disadvantages - the tendency to "caking" and deformation under temperature influences.

- Polyurethane foam. The advantages of this insulation are low thermal conductivity and resistance to external mechanical, biological and temperature influences, as well as corrosion resistance and long service life. Among the disadvantages, it should be noted the high cost and fire hazard.

Important! Polyurethane foam belongs to the G2 category in terms of flammability, it is an easily combustible material.

- Polyisocyanurate foam. It is an improved version of polyurethane foam.A distinctive feature of this insulation from the original is increased resistance to fire.

- Expanded polystyrene... This type of insulation is quite common, due to its advantages, the main of which are: good heat and sound insulation properties, resistance to external influences of various directions, as well as long service life and low volumetric weight. The main disadvantages are the "fear" of ultraviolet rays, fire hazard and susceptibility to destruction by rodents.

- Combined types of insulation. This category includes insulation made with mineral wool and expanded polystyrene. The combination of two types of insulation allows you to reduce the fire hazard threshold of the material, as well as improve its mechanical strength.

Types of sandwich panels

Currently, sandwich panels are produced in all regions of our country, due to their popularity and demand among developers. Some companies produce products in a fairly wide range, both by the type of materials used, and by the technical characteristics of the products obtained and their color schemes.

Sandwich panels for walls - facades of buildings and structures

The most common sizes of panels intended for cladding external walls of buildings and structures are shown in the following table.

| Specifications | Insulation type | |

|---|---|---|

| Mineral wool and expanded polystyrene | Polyurethane foam and polyisocyanurate foam | |

| Length, m | 1,5-20 | 2-13 |

| Width, m | 1/1,19/1,2 | 1,15 |

| Thickness, mm | 50-300 | 30-220 |

| Cladding thickness, mm | 0,5/0,55/0,6/0,65/0,7 | 0,45-0,7 |

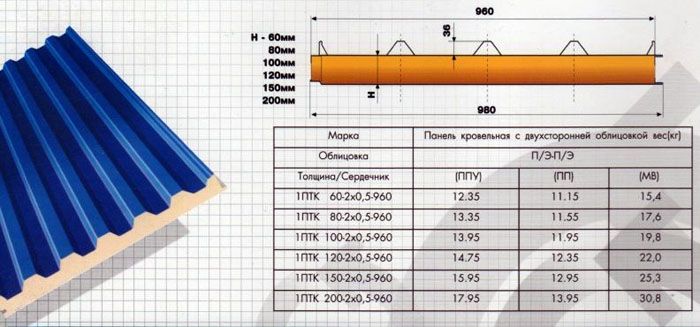

Roof sandwich panels

The main dimensions of the roof panels are shown in the following table.

| Specifications | Insulation type | |

|---|---|---|

| Mineral wool and expanded polystyrene | Polyurethane foam and polyisocyanurate foam | |

| Length, m | 1,5-20 | 2-13 |

| Width, m | 1 | 1 |

| Thickness, mm | 50-300 | 60-140 |

| Cladding thickness, mm | 0,5/0,55/0,6/0,65/0,7 | 0,45-0,7 |

The dependence of the weight of the roofing panel on its thickness and the insulation used is shown in the following figure.

Partition sandwich panels

For the installation of internal partitions, wall panels of small thickness or analogs made with PVC coating can be used. Sandwich panels of this type are distinguished by their low weight and low thermal conductivity, and products made of multilayer plastic are successfully used in finishing and insulation of door and window slopes. The main technical dimensions of PVC sandwich panels are shown in the following table.

| A type | Thickness, mm | Outer layer thickness, mm | Width, mm | Length mm |

|---|---|---|---|---|

| Without renolith film | 10/24/32 | 1 | 1500 | 3000 |

| HPL and foil 1 | 10/24/32 | 1,4 | 900 | 2000 |

| HPL and foil 1.4 | 10/24/32 | 2 | 1150 | 3000 |

Note! The abbreviation HPL informs about the production method of the product, which determines its structure.

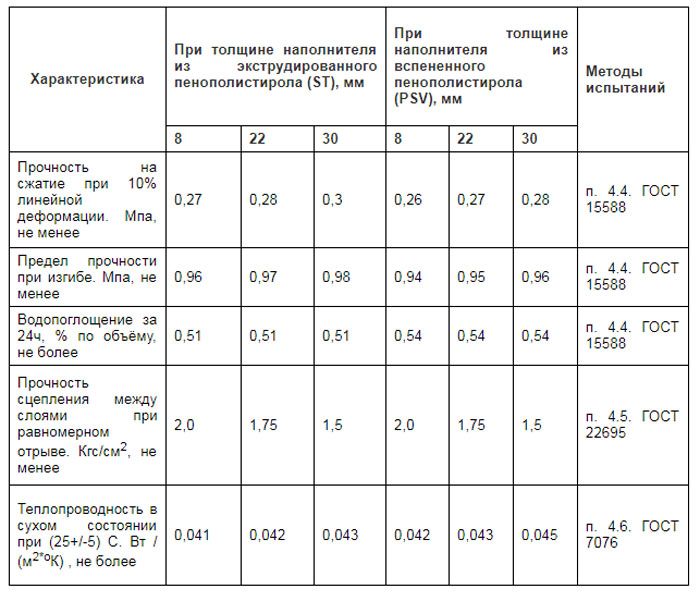

PVC panels differ in technical and thermal technical characteristics, depending on the type of insulation used

The characteristics of PVC sandwich panels are shown in the figure below.

Specifications are based on data provided by manufacturers

Leading sandwich panel manufacturers

As mentioned above, sandwich panels are produced in all regions of our country, but, nevertheless, some companies are most in demand in the building materials market, which is associated with their technical capabilities and the quality of products.

Note! The popularity of this or that company is due not only to its technical capabilities, but also to the region of location, as well as transport accessibility.

The most popular with construction companies and individual developers are such sandwich panel manufacturers as:

- "TSP-panel" ("ThermoSpecPanel"), St. Petersburg;

- "Lissant", Moscow;

- GC "Vesta Park", Moscow / g. Ryazan;

- Technostil, Gatchina, Leningrad Region;

- Stroypanel, St. Petersburg;

- LLC TD "Stimet", Lipetsk region;

- LLC Ural Plant of Building Panels, Sverdlovsk Region.

- LLC "Kostroma plant of building materials", Kostroma.

The production of sandwich panels is a complex technological process that requires special equipment

How to choose a sandwich panel - our editorial team's recommendations

As a rule, the size and brand of sandwich panels are determined by the designers at the stage of developing design solutions, but sometimes there are situations when you need to choose such a product yourself. In this case, specialists in the field of building materials or sales consultants who are involved in the sale of similar products come to the rescue. Our editorial office also has specialists who have experience with sandwich panels, and this is what they advise in a similar situation:

- The strength of the product depends on the thickness of the material used for the external and internal cladding of the panel, therefore this is the parameter that determines the reliability of the mounted structure.

- The weight of the panels depends on the type of insulation, as well as their thermal characteristics. Therefore, this parameter determines the possibility of using in a particular region of our country, as well as the need for construction equipment.

- When choosing panels, it is necessary to pay attention to the safety of the product, which must be informed by its certificate, which can be requested from the trading organization.

- When ordering panels, it is best to indicate their exact dimensions, and not to buy products by footage or running meters. This will avoid unnecessary waste resulting from installation.

Installation of sandwich panels can be carried out using construction equipment or without it, which depends on the volume of construction and the number of storeys of the facility being constructed

Installation of sandwich panels - the main nuances

The technology for performing installation work using sandwich panels depends on the construction object, its complexity and volume. Nevertheless, the main nuances that you should be aware of when performing such work can be formulated as follows:

- the bottom row of panels with a horizontal layout or their bottom - with a vertical one, it is necessary to protect against moisture penetration from the surface of the foundation;

- the outer protective layer of the panels is rather thin, therefore, it should not be damaged during installation work, and in case of violation, restore it using special materials;

- to lift the panels, it is necessary to use special suction cups, soft slings or special devices that ensure the safety of the panel surface at this stage of the work;

- if necessary, cut the sandwich panel initially, cut the metal cladding, and then the insulation;

- the joints of individual panels are filled with mounting foam, and the corner elements and frames of window and door openings are closed with additional elements;

- fastening of the panels is carried out using self-tapping screws (self-tapping screws) intended for this type of installation and corresponding in size to the thickness of the product to be mounted;

- in the absence of panel fastening units and their framing in the design documentation, such information can be found on the Internet, where there are unified options for such structures.

Related article:

Sandwich panel garage: characteristics of modern building materials, the choice of the optimal project, taking into account individual requirements, step-by-step instructions from buying the necessary products to performing installation operations - read the publication.

How much do sandwich panels cost

The cost of sandwich panels depends on the materials used, overall dimensions, as well as the region of their sale. The following table shows the cost of one square meter of panels produced by one of the most popular manufacturers of such products - the TermoSpecPanel company. The price is indicated as of the beginning of the III quarter of 2018.

| A type | Insulation | Cost (as of July 2018), RUB - with thickness (mm): | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 50 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | ||

| Wall, 1190 mm wide | mineral wool | 1190 | 1210 | 1290 | 1335 | 1400 | 1495 | 1650 | 1830 |

| styrene foam | 1075 | 1095 | 1155 | 1210 | 1265 | 1345 | 1485 | 1655 | |

| Wall, 1000 mm wide | mineral wool | - | 1260 | 1330 | 1390 | 1450 | 1550 | 1710 | 1870 |

| styrene foam | - | 1145 | 1205 | 1255 | 1305 | 1395 | 1535 | 1685 | |

| Roofing | mineral wool | - | 1310 | 1370 | 1430 | 1495 | 1590 | 1755 | 1930 |

| styrene foam | - | 1205 | 1255 | 1305 | 1365 | 1445 | 1595 | 1755 | |

Using sandwich panels of various colors, you can add variety to the design style of an industrial or other construction object

It is interesting that, as a rule, residential buildings from sandwich panels are not built, so there are not so many consumer reviews about this building material.

Video: cargo service station from sandwich panels

Share your opinion and ask questions in the comments!