The technology of laying paving slabs on sand: the choice of material and soil preparation

Happy owners of a private house or a summer cottage often think about arranging a yard. I wish that not only the interior was attractive, but everything around it too. Therefore, consumers are thinking about creating tracks from various materials. For example, the technology of laying paving slabs on sand has its own characteristics. But the result is neat and durable.

The content of the article

The advantages of paving slabs and the variety of its variations

The variety of sidewalk tiles is amazing. Material specifications depend on manufacturing method and material. There are types of concrete, clay, with the inclusion of natural stone and others. Among all the variety, there are three main subtypes:

- released by vibrocasting;

- vibrocompression;

- hydraulic pressing.

The first tile is prepared from a concrete mixture poured into a plastic mold. The mixture is kept on the table with constant vibration until it is fully compacted. Then it is transferred to a special drying chamber. This is a simple production method, but these models are not very durable. However, it suits well for giving.

The second and third method is used more often in the manufacture of sidewalk tiles, and the range of applications for the finished material is much wider. All sidewalk paths and pavements are paved with just such tiles.

There are quite a few advantages of such a material for laying paths and pavements:

- ecological production;

- high strength indicators;

- resistance to temperature extremes;

- ease of use;

- large selection of models;

- low installation costs.

Due to these qualities in private construction, paving slabs are used more often than asphalt pavement, and it looks better on city streets.

Of the shortcomings, only two points are distinguished that do not affect the popularity of the material:

- in severe frosts, the surface may slide;

- if the technology of laying paving slabs on sand or other soil is not followed, the slab sags.

It turns out that only one defect is associated with the material itself, the drawdown can be easily eliminated provided that all installation requirements are met.

Options for laying tiles for paths in the country, prices for work

Tile is a wonderful decorative material, so for large personal plots, it allows you to bring real fabulous paths to life, and for small ones - to make neat walkways. You can spread it in different versions:

- chess order;

- herringbone;

- weave;

- circular option;

- chaotic pattern.

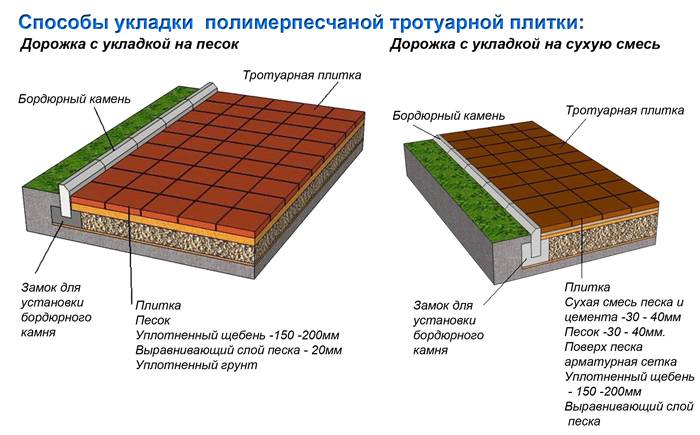

Such laying options depend on the shape and size of the tile, as well as its color. There is another classification - by the way of laying:

- on wet sand;

- on a mixture of sand and cement;

- for a slurry of cement and sand.

Laying of paving slabs in the country is most often done in the first way, it provides a high percentage of moisture absorption during operation. The second method requires a mixture of 5 parts of sand and one cement. It is distributed on the surface by pouring water.

The third method provides the highest quality. The proportions of the components are the same as in the previous version, but the solution is prepared only with the help of special equipment, and laid with a layer of more than 30 mm on the prepared soil.

Of all the options for laying paving slabs, we will consider in detail the simplest and most suitable for giving - on wet sand.

Technology for laying paving slabs on sand: features

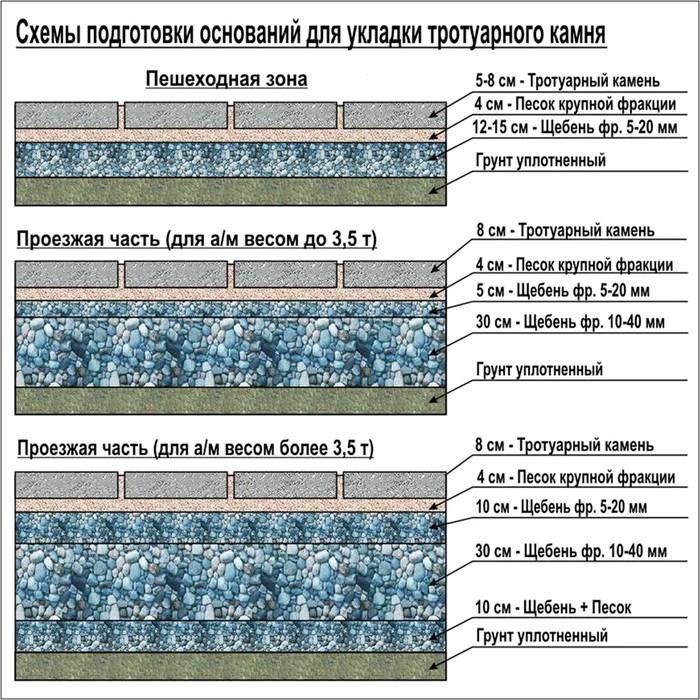

Despite all the variety of tiles and laying technologies, craftsmen prefer the general sequence of actions when performing work:

- Remove the top layer of soil (about 15 cm).

- Form longitudinal and transverse slopes for liquid drainage.

- Select the boundaries of the plot.

- Make a 7 cm sand pillow.

- Smooth and compact the surface.

- Lay a layer of a mixture of sand and cement, leveling it with a level.

- Mount the tiles and tamp them.

- Close up the seams.

In this case, the material itself should be laid from the curb, moving towards the middle. The direction of work will be away from yourself, otherwise the evenness of the surface can be disturbed. If irregularities appear during the work, they are immediately corrected with the help of sand. The seams are treated with a dry mixture of sand and cement.

If you do not decide on your own to lay the paving slabs, the price for the work will be different, it depends on the volume and region of location. So, in Moscow and the region, the cost of one square meter on a turnkey basis starts from 350 rubles. In St. Petersburg, together with the material, the work will cost 1,800 rubles. per m².

The cost of the tile itself

To make it easier for you to calculate how much it will cost to arrange paths in the country, here are some examples of the cost of paving slabs.

Table 1. Average cost of tiles

The thickness of paving slabs varies from 20 to 60 mm. You can choose any pattern and size suitable for the track you plan to create. Calculate the number of elements based on the total track area.

Related article:

Rubber tiles for paths in the country. In the review, we will consider the field of application of the material, average prices and characteristics, tile laying technology and useful recommendations from specialists.

DIY step-by-step instructions for laying paving slabs with photo examples

The technology of laying paving slabs on sand implies compliance with all stages of work, including the preparatory one, where a whole list of tools and raw materials should be prepared:

- sand in a fairly large amount, which depends on the area;

- paving slabs purchased with a stock;

- border;

- cement;

- strong thread, pegs and a strip for fencing the site;

- rubber-tipped hammer, shovel and long rule;

- two tubes of steel with a diameter of 1 ';

- ramming equipment;

- wheelbarrow;

- level, trowel, buckets and whisk;

- grinder with discs for concrete;

- knee pads - useful if you don't want to injure your legs while working.

Before starting work, decide on the slope that must be observed for water flow. Better to do it in the direction of the street (zero mark).

Table 2. Technology of laying paving slabs

Helpful information!It is best to start working in the spring or fall when it is not so hot that the mixture does not dry out quickly.

When you finish the work, you get a neat path to the dacha. Here is a video material on laying paving slabs with your own hands in order to fully understand all the nuances of the work:

Video: DIY paving slabs

Related article:

Video of laying paving slabs with your own hands. In the article, we will consider in detail the types, pros and cons of the material, step-by-step instructions for laying tiles, advice and recommendations from specialists.

At the end

Using paving slabs to create neat country paths is the best option. Such a design will last a long time if all the nuances of styling have been observed. You can do the work yourself or contact the masters, the price of whose work is different depending on the region and the amount of work.

Using such material, you can create real masterpieces near your home, decorating the site.