Do-it-yourself fence from a professional sheet: photos, materials, construction algorithm

PRoflist is an easy-to-use and relatively inexpensive material. It is great for both roofing and fencing. How to build a fence from a professional sheet with your own hands? Photos, expert recommendations and step-by-step instructions will help you install a durable and beautiful fence on the site.

The content of the article

- 1 Pros and cons of corrugated board as a material for a fence

- 2 Professional sheet for a fence: sizes, prices, brands

- 3 Fences from a professional sheet: photo options

- 4 How to build a fence from a profiled sheet with your own hands: a sequence of actions

- 5 Do-it-yourself fence from a professional sheet: photos and recommendations of professionals

- 6 Video: DIY installation of a fence

Pros and cons of corrugated board as a material for a fence

Metal profile is one of the most inexpensive universal building materials. It is suitable for roofing, fencing, gazebos and outbuildings Location on.

The advantages of corrugated board for fence:

- a large selection of patterns and colors;

- ease of transportation and installation;

- resistance to moisture and frost;

- fire resistance;

- durability.

Among the disadvantages it is worth noting:

- not the cheapest material;

- if necessary, repair (painting, straightening) loses its ideal appearance;

- has a large windage, in places with strong winds it crumples and falls off the base.

It is worth recognizing that the advantages of a professional sheet for the construction of fences are obvious, and a few disadvantages can be compensated for by careful maintenance and reliable fixation of the material.

Professional sheet for a fence: sizes, prices, brands

The metal profile for the construction of the fence should not only hide the site from prying eyes, but also be strong enough to withstand wind and rain, and accidental mechanical damage.

Standard dimensions of a professional sheet for fences and their marking

The metal profile has three standard markings:

- grade N - used for roofing;

- grade C - suitable for fences and walls;

- grade NS - is considered universal and is used for roofs and fenceov.

After the letter in the marking of the sheet, there are numbers.They indicate the height of the ridge. For example, the C35 mark means that the wave height on this profile is 35 millimeters. The length of the corrugated board varies from half a meter to fourteen meters. The standard length is 2 meters.

| Brand | Full width, mm | Working width, mm | Flange height, mm | Material thickness, mm | Step m / d ridges, mm |

|---|---|---|---|---|---|

| C8 | 1200 | 1150 | 8 | 0.4-0.8 | 62.5 |

| C10 | 1155 | 1100 | 10 | 0.4-0.8 | 45 |

| C20 | 1150 | 1100 | 20 | 0.45-0.7 | 137.5 |

| C21 | 1051 | 1000 | 21 | 0.4-0.7 | 65 |

| HC35 | 1600 | 1000 | 35 | 0.5-0.9 | 70 |

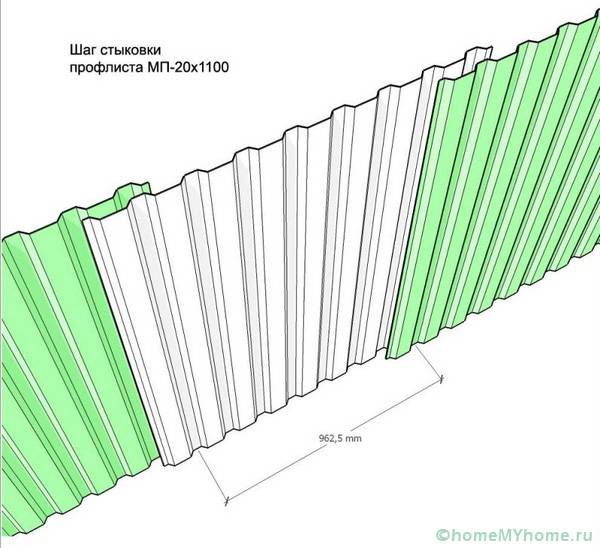

Helpful information! For corrugated sheets, one edge of the wave is slightly smaller than the other. This should be taken into account when joining the material. The larger wave is superimposed on top of the smaller one.

Professional sheet for the fence: product price

| Profile view | Brand | average price r / m2 |

|---|---|---|

| Galvanized 0.35 mm | C8 | 170 |

| C10 | 199 | |

| C20 | 206 | |

| C15 | 212 | |

| HC35 | 238 | |

| Polyester coating 0.35 mm 25 μm | C8 | 224 |

| C20 | 234 | |

| HC35 | 270 | |

| C15 | 270 | |

| C10 | 276 | |

| Galvanized 0.4 mm | C8 | 199 |

| C20 | 207 | |

| C10 | 216 | |

| HC35 | 225 | |

| C15 | 228 | |

| Polyester coating 0.4 mm 025 μm | C8 | 260 |

| C20 | 272 | |

| C10 | 279 | |

| K25 | 281 | |

| C15 | 290 | |

| HC35 | 299 | |

| Polyester double-sided 0.4 mm 025 microns | C8 | 298 |

| C20 | 311 | |

| C21 | 340 |

Fences from a professional sheet: photo options

Metal profile fences, with all their undoubted advantages (reliability, durability, cheapness), are still inferior to many other options for fences in aesthetics. It should be admitted that a dull row of a monophonic profiled sheet does not decorate the site. Craftsmen offer numerous options for making a fence made of profiled sheet with their own hands. Photos of performance options inspire ideas and experiments on your own site.

The combination of different building materials with corrugated board gives numerous variations of fences. For combinations, you can use stone and brick, forging, picket fence and other materials. Planning construction fence, should be considered landscape and site design and the facade of the house. If you skillfully combine colors and elements, the fence will become part of the ensemble.

The classic is the option of a fence made of stone or brick pillars and corrugated sheets. A solid base must be provided for each post. The supports are connected with a plinth reinforced with a metal bar. The secret of the attractive appearance of such a fence is in the skillful selection of colors. Brown and green profile colors are best combined with brickwork, and shades of gray with stone.

One of the simple finishing options is to decorate the edge with an edging strip. This strip is able to protect the edge of the sheet from moisture and will give each individual section additional rigidity. Such fence elements can be combined with other materials.

A novelty on the modern market is a sheet with offset printing. Images on such material can be very different, from imitation of brick or masonry, up to panoramic photos of nature.

A curly edge gives originality to the usual corrugated board. Such material for fencing began to be sold quite recently. The edge is treated with a corrosion-resistant coating and confidently maintains its integrity.

An excellent combined option is a fence using a metal picket fence. It is durable and looks pretty attractive. Picket fence color can be selected in accordance with the main range of the fence. Such a fence will harmoniously fit into any landscape.

Elements of forged metal will give the fence an exquisite look. They can be ordered individually or purchased as ready-made fragments. If you place them not only on the fence, but also on the facade of the house, you can achieve the unity of the ensemble.

Another way to decorate corrugated board is to use plasma cutting for metal. This high technology allows you to create openwork jewelry of any complexity from computer sketches.Profiled sheet fences, photos of which are given below, are made using this technology.

An uncomplicated and attractive way to decorate fence - gardening. Ornamental shrubs and trellises for loaches can be planted along the fence.

Related article:

Fences for private houses: photo ideas. In a separate publication, original ideas and examples of fences made of different materials for every taste are presented.

How to build a fence from a profiled sheet with your own hands: a sequence of actions

Most of the owners of suburban areas set themselves the task: how to build a fence from a professional sheet with their own hands? In fact, this is possible, especially when the home master has at least one assistant.

Tools:

- hand drill with a diameter of 25 centimeters;

- rope, construction level, yardstick;

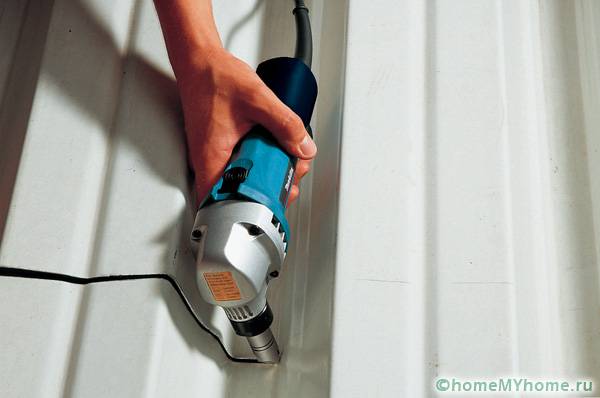

- a drill with a metal cutting attachment, metal scissors;

- sledgehammer, screwdriver;

- electric welding unit.

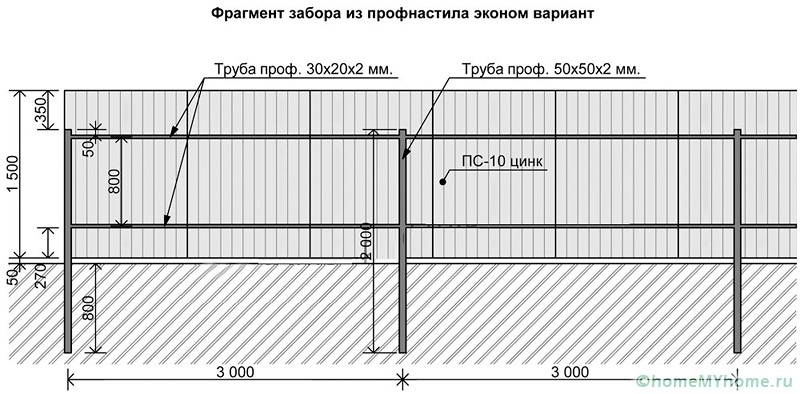

Approximate calculation of materials for a 10 meter fence:

- Profile sheets (width 118 cm) - 9 pcs;

- Pipes for stands 270 cm length - 5 pcs;

- Transverse logs - square metal profile 20X20 - 30 meters;

- A bag of cement, gravel.

- Self-tapping screws for metal - about 10 pcs per square meter.

Stages of installing a fence from a profiled sheet with your own hands:

Stage 1 - design

At first glance, it seems that building a fence is a task that does not require a particularly careful approach. But the economical consumption of material and the strength of the future structure depend on how carefully the measurements are made and the project is prepared. That is why it is important to draft a fence. After examining the territory with a tape measure, you can sit down in the old fashioned way with a pencil and a ruler over paper - graph paper or use modern computer technologies. When designing, it is important to take into account the unevenness of the terrain and the characteristics of the soil.

Stage 2 - installation of supports

In the marked places, holes are drilled with a drill to a depth of one meter. They are equipped with pillars-supports, pre-treated with a composition against corrosion. It is important with the help of a building level to align the supports strictly vertically, otherwise the fence will be skewed. Small stones or crushed stone are poured into the free space of the pits and poured with concrete. After that, you need to wait at least three days for the solution to finally solidify.

Stage 3 - transverse lags

If the fence is not high, two transverse rows of fasteners are sufficient. But for a fence from 1.8 meters, it is better to install an additional third row. Transverse joists are welded to the posts. Welding spots are additionally painted over.

Stage 4 - fastening the sheets

The metal profile is fixed on the crossbars with self-tapping screws. It is better to use roofing screws, their kit includes sealing gaskets that do not allow moisture to pass through. It is important to remember that the edges of the profile are slightly different in wave size and must be joined correctly. Some people prefer to attach self-tapping screws to each wave.

Self-tapping screws to match the color of the corrugated board are practically invisible on the fence

Stage 5 - final finishing

After fixing the sheets, you need to check the entire structure for cracks, chips and scratches. All damage is painted over with a suitable paint.

The installation process is described in detail in the following video:

Do-it-yourself fence from a professional sheet: photos and recommendations of professionals

- When working with a metal profile, you need to protect your legs with strong shoes and use wooden supports so that the edge of the sheet does not deform.

- The professional sheet is not fastened with nails, such a structure will be torn off from the supports at the first strong wind.

- When working with a profile, gas welding equipment is not used.

- Professionals do not recommend cutting the sheet with a grinder - it removes the protective layer, and the edge of the sheet will quickly rust.

- A couple of months after installation, you need to slightly tighten the screws.

It is quite possible to build a fence from a professional sheet with your own hands. It is important to choose the right material in terms of rigidity and dimensions, take into account the peculiarities of the terrain. For greater attractiveness, it is recommended to combine the metal profile with other building materials. If you take care of such a fence and handle minor damage in a timely manner, it will last for more than a dozen years.

Video: DIY installation of a fence