Decking - decking: analysis of characteristics, advantages and disadvantages, features of use

Towards modern building materials make more and more stringent requirements, the most important of which is a harmonious combination of environmental safety and high performance. In this sense, decking (decking) is one of the best finishing materials with a wide range of applications and unique technical parameters. In this article we will analyze the technical and operational characteristics of the main types of decking. We will describe the advantages and disadvantages of the material, selection criteria and features of use.

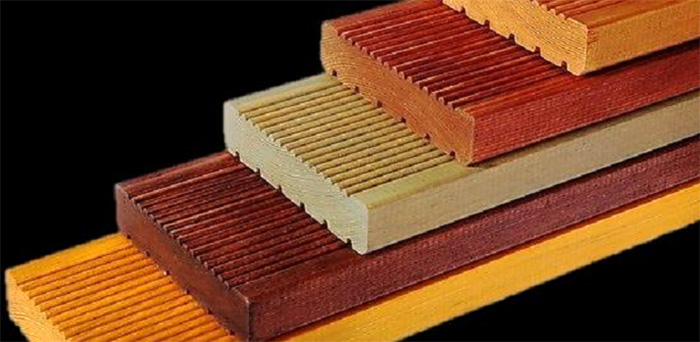

Decking is a modern artificial finishing material that surpasses natural ones in its parameters

PHOTO: woodplast.com

The content of the article

Use of decking

High-quality decking, with proper care, is weakly susceptible to any, even extreme, atmospheric manifestations and intense physical stress. High strength and performance characteristics allow this material to be used as a decorative and protective finish for the following structures:

- Outdoor floor coverings: garden paths, terraces, open verandas etc.

- Not glazed balconies and loggias;

- Pedestrian areas of piers, marinas, embankments and quays;

- Deck coverings for river and sea vessels;

- Interior decoration, including those with constantly changing humidity and temperature: baths, showers, saunas.

Objects and building structures using decking as cladding:

Types of decking and their characteristics

Decking is usually classified according to the type of raw materials used and the way it is processed. Depending on this, its operational characteristics and scope of use differ significantly.

Decking made of solid wood or with closed edges can be used not only for cladding floor coverings

PHOTO megastrolis.ru

From an array

Solid wood decking is actually an additional processing of the floorboard to give it special properties that allow the material to be used in extreme conditions. The most budget products are not subjected to any processing and are made from ordinary coniferous wood: spruce, larch, pine. The raw material for the more expensive coating is oak, cedar, Karelian birch, ash. Elite products are made from exotic wood species: wenge, merbau, grappa, cougar, etc.

To protect against mechanical stress and biological corrosion (rot, mold, fungus), solid wood decking is subjected to special processing:

- Impregnation... The technology consists in the impregnation of wood products with fugicidal substances under the influence of vacuum. Provides an adequate level of protection for up to 15-20 years. During this period, the board does not need additional processing;

- Heat treatment... The machined workpieces are heated in special autoclaves up to 200 ° C. This increases the density of the outer layers and gives them a moisture repellent effect. However, brittleness of such material increases and the fall of heavy objects, even from an insignificant height, can lead to the formation of chips and cracks.

WPC terrace board

WPC (wood-polymer composite) is a material consisting of wood flour as a filler and a polymer binder. There are several options for WPC, which differ both externally and in their operational parameters. They are classified according to the degree of filling the plastic with wood elements:

- Weakly filled (20-40%) - such a decking board looks like plastic. Recommended for objects with high mechanical stress on the surface;

- Medium filled (40-60%) - the best option for domestic use. Sufficiently high strength and resistance to high humidity and fungus, combined with environmental friendliness and decorativeness;

- Highly filled (up to 80%) - the material demonstrates some of the disadvantages of wood: high abrasion, moisture and frost deformation.

Sizes and color palette

Both the technical and decorative characteristics of solid wood and WPC decking differ significantly. However, manufacturers, whenever possible, try to bring the main dimensions of the product to certain standards:

| Parameter | Array | DPK |

|---|---|---|

| Width, mm | 90-250 | 140 |

| Length, m | 1,5-4 | 3-6 |

| Thickness, mm | Thin 18-22 Average 25-30 Thick 42-48 | Average 28 Decking tiles: 25x25 ... 50x50 |

| Color palette | Natural color and texture. Tinted in any colors and shades typical for timber | Limited color gamut. The colors are saturated unnatural. |

| Front surface | Smooth Corrugated | Smooth (with an imprint of a woody texture, insignificant in relief); Corrugated |

| Back surface | Solid (no ribs); Anti-warping rip cuts | Solid - close to the floorboard in strength; With thin ribs - not load-bearing, fits on a solid base; With thick ribs - load-bearing, fits on logs. |

| Internal structure | Solid array | Solid array; Closed stiffeners. |

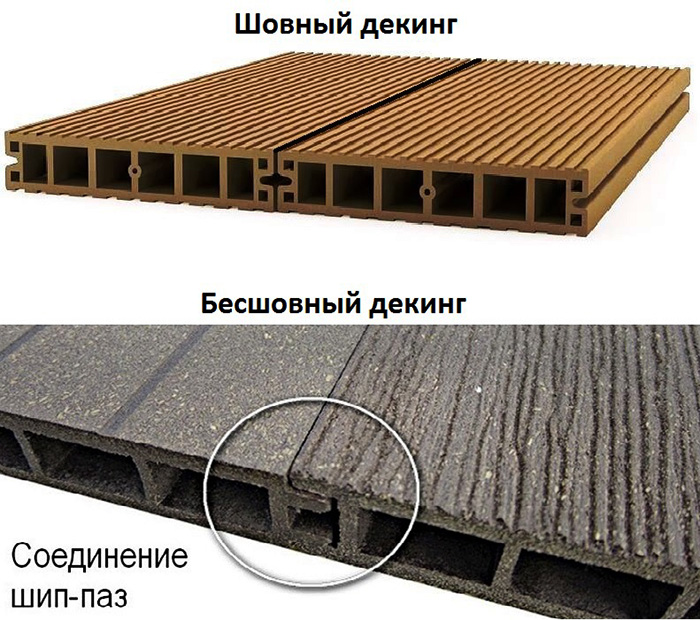

Depending on the type of connection, the following types of decking are distinguished:

- Suture decking - the gap between the individual elements is 5-10 mm.As a rule, this is how solid wood materials and highly filled WPC are laid, which are characterized by a high level of moisture and temperature deformation.

- Seamless decking (joint "thorn-groove" or selected quarter) the deformation gap does not exceed 2-3 mm and is completely covered by the elements of the tool joint. The construction of the flooring acquires additional rigidity, but its installation should be done with a slope of 1.5-2 ° for rainwater drainage.

Important! WPC decking is more prone to fading than solid decking, since impregnations and varnishes cannot be used to protect it.

Advantages and disadvantages of using

The use of decking in various building structures has both advantages and disadvantages. Of the most tangible advantages for the user, the following are worth noting:

- Durability... The service life, depending on the type and manufacturer, is 15-20 years;

- Moisture-frost resistance... Treated wood and wood-polymer composite do not absorb moisture, therefore, they do not deform under the influence of internal frost swelling;

- Resistance to biological damage of any type: rot, mold, fungus, woodworm beetles. The exceptions are rodents, which quite easily gnaw through the composite and heat-treated massif. Rodents try to avoid impregnated wood.

- Strength and durability... Depending on the type, decking has a compressive strength of up to 25 MPa and up to 50 MPa for bending. This allows you to use a full-bodied decking as a covering for garages and driveways for light vehicles;

- Exact geometric dimensions... Decking boards have a clear predetermined shape with an error of no more than 1 mm per running meter. This greatly facilitates the installation process.

However, decking also has certain technical limitations:

- High cost of material and auxiliary elements;

- Difficulties in laying, it is necessary to strictly adhere to the technology for performing work, especially the preparatory stage;

- When laying, it is necessary to observe technological gaps from 3 to 15 mm, which subsequently are rather difficult to clean.

One of the types of decking "garden parquet" can be laid simply on a gravel base

PHOTO o-drevesine.ru

Leading manufacturers

The production of decking, both from solid wood and from composite, is a high-tech production. However, the widespread popularity of this material has led to the emergence of many imitations and outright fakes, which outwardly resemble decking, but do not have its advantages. Of the most reliable and popular decking manufacturers, the following can be noted:

- TREX (USA) - solid composite decking with a service life of up to 25 years;

- WOOZEN (South Korea, part of LG Corporation) - produces hollow decking with wood texture on the front side. Service life up to 10 years;

- HOLZDORF (Ukraine-Germany) - hollow board with tenon joints. Service life 7 years;

- ECODEK (Russia) - Hollow and full-bodied WPC. Has an affordable cost. Service life 7 years;

- JUNGLWOOD (Indonesia, Portugal), Ital Parchetti (Italy) - decking from an array of exotic tree species.

Selection criteria for decking

When choosing a decking, in addition to color preferences and / or texture imitating wood, you should pay attention to some technical characteristics.

- Edge shape... It can be straight, beveled, lock-joint or rounded. When choosing it, you need to focus not only on design solutions, but also on the features of the laying technology.In some cases, a base (monolithic concrete slab) may be required at a cost comparable to the price of the terrace board itself.

- Face surface... It can be smooth or embossed with an anti-slip effect. For open areas, near pools and in showers, it is more advisable to use the second option. Decking with a smooth surface is more convenient for cleaning.

- Density... This parameter is key for the WPC. The more loads the flooring is subjected to, the higher the density of the decking should be. Therefore, solid wood elements with a density of 500-1000 kg / m3 are recommended for domestic use, and WPC (density 1000-1500 kg / m3) can be used for facing surfaces with increased permeability.

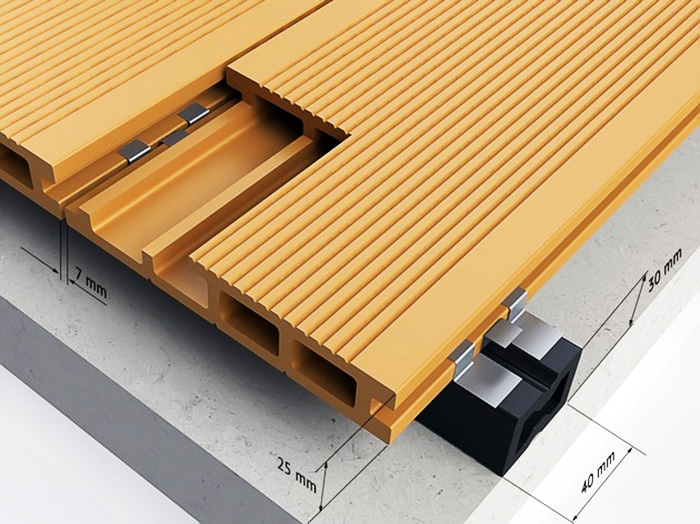

- Profile... Solid wood decking is always made monolithic. WPC can have both a monolithic structure and closed and open stiffeners. At the same time, WPC with thin stiffeners is used for cladding structures that do not have significant mechanical effects - house facades, fences, etc. Laying is done on a thoroughly cleaned, perfectly leveled base. Decking with thick ribs can be laid on logs.

Laying methods

There are two main ways to install decking:

- Open... The deck is screwed to the logs with screws through and through, through the front surface. Creates the visual effect of riveted boards. This method is not suitable for all exterior styles (loft, urban, country, Provence). Self-tapping screws are used only with anti-corrosion coating. When fixing in the board, a hole is pre-drilled and only then the screw is tightened.

- Closed... Special fasteners - "clips" are attached directly to the decking board, and then to the bearing lags. Practiced for solid wood decking. This installation makes the flooring more aesthetically pleasing, but takes a lot of time.

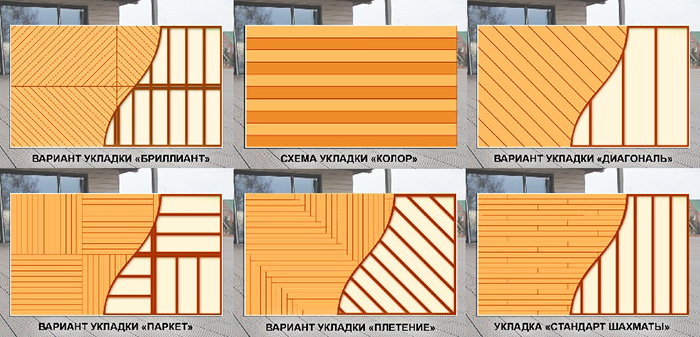

Depending on the way the boards are arranged, the following types of laying are distinguished:

- Diamond;

- Color;

- Diagonal;

- Parquet;

- Weaving and many others.

Of these, the most economical is the diagonal, since it allows you to fully use all the cuts of the boards.

Video: decking installation rules

Features of operation and maintenance

WPC decking practically does not need additional processing. Its resistance to external weather factors, its further processing is economically inexpedient, since protective compounds will extend the service life of the material only slightly.

Solid wood decking, despite the special treatment, needs periodic impregnation with special compounds:

- Antiseptics and fungicides;

- Varnishes - create moisture-repellent coatings. As a rule, transparent varnishes with an alkyd composition are used;

- Paints - an almost complete range is used: latex, polyurethane, oil, alkyd, etc.

Oils are one of the best options. Oils do not change the texture depth and color of the material. Increases durability and protects the product from fading. Suitable varnishes for decking are: Neomid, V33, Vallti.

conclusions

Decking, especially made of WPC, is one of the most technologically advanced materials with a wide range of applications. However, you should carefully choose such material so as not to purchase a low-quality fake.