How to choose and buy bathroom wall panels

The building materials market is constantly updated, due to the emergence of new technologies and the competition between manufacturers for a potential buyer. This applies to roofing materials and structural elements, paints and varnishes and finishing materials. Wall panels for bathrooms, what are they and how to use them, advantages and disadvantages, as well as how to choose and install - this is the topic of this article.

The content of the article

- 1 What are the moisture resistant wall panels for bathrooms?

- 2 Features of choice in size and appearance

- 3 Methods for attaching panels to walls

- 4 How correctly and at what price can you buy wall panels for the bathroom, taking into account the elements for installation

- 5 Video: "Finishing the bath with PVC panels"

What are the moisture resistant wall panels for bathrooms?

Currently, manufacturing enterprises produce a number of moisture resistant panelsthat can be used for finishing damp and damp rooms. These include bathrooms and showers, kitchens and bathrooms. In the manufacture of such products, various bases are used, which provides each type of product with certain properties, both in terms of installation and use, and in terms of price and service life. The most widespread among developers are wall panels made on the basis of PVC and MDF, fiberboard and chipboard, as well as acrylic and glass modifications.

PVC based models

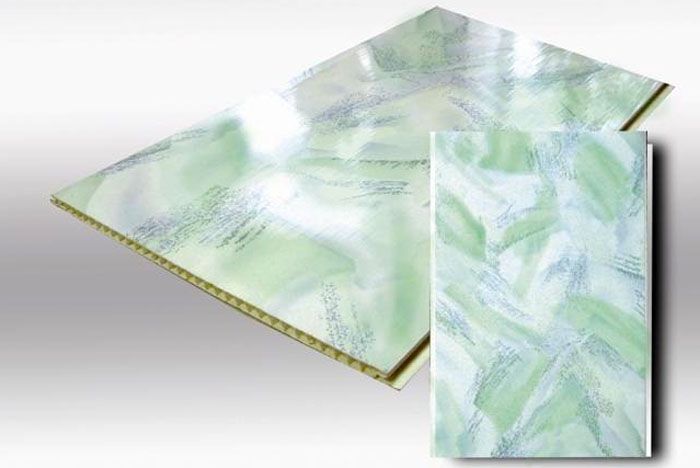

Wall PVC panels belong to the class of polymer finishing materials, because in their manufacture, polyvinyl chloride is used. A certain pattern is applied to their outer surface, for which various types of printing are used (offset, thermal, lamination), after which a layer of varnish is applied. The varnish can be matte or glossy, which significantly increases the attractiveness of this type of product and their range.

The advantages of this group of models are:

- universality of use;

- ease of installation and maintenance;

- strength and ability to maintain their geometric dimensions during temperature fluctuations;

- thermal insulation properties and the ability to improve sound insulation;

- a variety of colors and types of imitation of various natural materials (wood, stone, brick, etc.);

- moisture resistance.

The disadvantages of this type include the following indicators:

- exposure to ultraviolet rays;

- low strength under external mechanical stress;

- the possibility of the presence of a specific smell in the cheapest models.

In addition, disputes about the environmental safety of building materials made on the basis of synthetic substances do not subside. According to manufacturers, PVC panels are environmentally friendly, however, there is another opinion.

Each type of design is assigned a specific name, which simplifies the search for the required series

By their design, PVC panels are two planes connected by stiffening ribs. The strength of the product is given by the presence of polyvinyl chloride. By the type of use, PVC panels are classified as wall and ceiling, which is reflected in their design style and geometric dimensions. The wall modifications are thicker and therefore heavier.

According to the width of the manufactured products, plastic panels are classified as follows:

- lining - the width is 100-125 mm, and the length, as a rule, is 3 m, with a narrow and wide type of lock connection, which are called "polka" and "european", respectively;

- leaf - 80-200 mm wide and 100-400 mm long, can be made in the form of PVC tiles, colored mosaics or in another style of decoration;

- panel - 250 mm wide, 2600/2700/3000 mm long;

- sandwich panels - are two layers of plastic, between which polyurethane foam or expanded polystyrene is laid.

Related article:

PVC panels. In the publication, we will consider the advantages and disadvantages, varieties, sizes, characteristics of ceiling and wall products, average prices, selection criteria, the nuances of DIY installation.

MDF products

MDF panels are made from woodworking waste, as well as low quality wood. In the production process, the raw material is crushed and in the form of small particles, dust-like fraction, pressed under high pressure in a vacuum chamber. Ligin is used as a binder. The surface of MDF is covered with paper imitating the structure and color of various types of wood, and to impart moisture-resistant qualities, the surface is laminated, for which a moisture-proof polymer film is used. For bathrooms, it is precisely moisture-resistant MDF with a water-repellent effect that is used.

The advantages of MDF products are:

- relatively low cost;

- ease of installation and ease of processing;

- are good heat and sound insulators;

- long service life;

- environmental friendliness;

- good water-repellent properties (for laminated series).

The disadvantages are:

- low resistance to external mechanical damage;

- are flammable.

By their size and appearance, these products are classified as type-setting (rack), slab and sheet. Typesetting or rack-and-pinion - they look like a lining and are narrow (150 mm wide) and wide (250 mm wide). The length of such products is 2600 mm.

Tiled models are made in the form of a rectangle of different sizes (from 300 to 950 mm) and design style. This type of laminated panel is often used in the decoration of washrooms, showers and bathrooms. The sheet modifications are specially designed for rooms with high humidity, and the water-repellent properties are enhanced by the use of melamine, which is used to treat the surface before lamination. The width of the products in this group is: 695/1035/1220 mm, and the length is 2070/2344/2440/2800 mm.

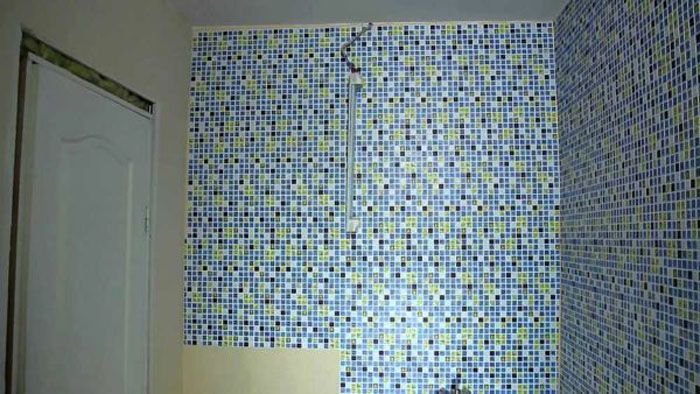

Feedback on MDF panels installed in wet rooms:

Related article:

From this article you can learn about MDF: what is it, important characteristics of this material, its advantages over alternative options and a lot of other useful information.

Fiberboard models

When making Fiberboard panels also used low-grade wood and waste woodworking enterprises, however, in this case, the raw material is cut to the state of shavings, and then pressed using adhesive components. To make the fiberboard water-repellent, the outer surface of the products is covered with melamine laminate or polymer film.

The advantages of this finishing material are:

- strength and durability;

- universality of use;

- ease of installation and maintenance;

- low cost.

Of the shortcomings, it should be noted the small thickness, which does not allow to hide the defects of building structures during direct installation on their surface.

By the types produced by the industry, fiberboard is classified as superhard, solid and semi-solid, as well as insulating-finishing and insulating.

For the finishing of wet rooms, hard and semi-hard types of fiberboard are used, covered with a protective layer and having a thickness of 3–8 mm, with dimensions of 1800 × 3600 mm.

Reviews of fiberboard panels used in wet rooms:

Related article:

Fiberboard: what is it. Sheet dimensions, thickness and price, advantages and disadvantages, types of material, features of working with plates, useful tips and recommendations of specialists - read the publication.

Chipboard panels

Chipboards are made by mixing shavings and sawdust, then hot pressing and adding binders.

The advantages of this building material are:

- high resistance to external mechanical stress;

- long service life;

- ease of maintenance and care;

- resistance to ultraviolet radiation;

- affordable cost;

- possibility of reuse.

The disadvantages of this group of materials include:

- low strength of furniture and interior items fixed on their surface, due to chipping of the material structure (when using self-tapping screws and other fasteners);

- ability to absorb moisture;

- react negatively to changes in the operating temperature.

For the decoration of bathrooms and other rooms where there is a high moisture content, only panels treated with special compounds are used. These grades of fiberboard are distinguished by their high cost, therefore, particleboard is used less often to decorate such premises than other analogues discussed above.

Related article:

Chipboard grooved moisture resistant: advantages and disadvantages, sizes, average prices, reviews, secrets of proper installation of plates with your own hands and other useful tips - read in our review.

Acrylic panels

Acrylic is a polymeric material made of acrylic and methacrylic acid, which is 100% waterproof, which determines the scope of its use.

Depending on the components used in their manufacture, acrylic panels can be transparent or matte, colored or solid, and have a glossy or rough outer surface.

The advantages of acrylic products are:

- high strength;

- waterproofness;

- light weight;

- resistance to ultraviolet radiation and abrasion;

- environmental safety of the material and the absence of odor;

- not subject to decay and the formation of microorganisms, mold and fungi;

- ease of cleaning and maintenance;

- a variety of colors and styles.

The main disadvantage is the high cost.

For the decoration of the premises, including the bathrooms, acrylic panels based on MDF are used. The acrylic layer applied to the base is 1–1.5 mm, and the geometrical dimensions correspond to the dimensions of the MDF blanks.

Feedback on acrylic models:

Glass wall panels

Glass is an absolutely moisture-proof material, however, its ability to break down under external mechanical influences made it impossible to use for interior decoration both outside and inside. The development of technologies has made it possible to make glass sufficiently strong, but at the same time retaining the main advantage - its transparency. The presence of a protective film applied from the outside fully ensures the safety of using this type of panels.

Advantages of glass models:

- the ability to apply a pattern and texture of any kind and color scheme;

- resistance to temperature extremes and ultraviolet exposure;

- universality of use;

- ease of maintenance, because the outside is absolutely smooth and the pattern is applied on the inside.

The disadvantages include:

- the complexity of doing the installation yourself;

- relatively high cost;

- for washing, you must use special detergents that do not leave streaks.

To apply a picture on glass, several methods of work are used:

- Film printing - the drawing is applied to a thin film, and it is already glued to the glass panel from the inside.

- Triplex - the printed film is placed between two glasses, after which, under the influence of high temperature, the glass surfaces are soldered and become monolithic.

- UV printing - the most popular method based on drawing a pattern on the back of the glass using a special printer that uses resistant types of polymers as dyes.

The size and plot of the drawing is chosen according to the individual order of the developer, which allows you to make the decoration of the room in an absolutely individual style.

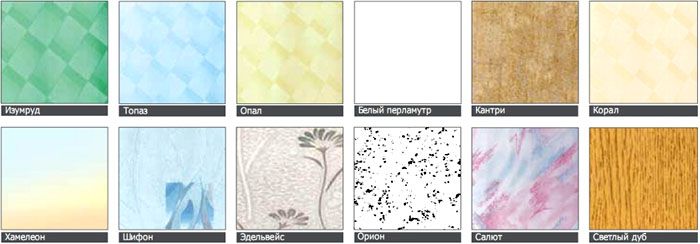

Feedback on glass wall panels when installed in wet rooms:

Features of choice in size and appearance

The presence of a large number of proposals, both in terms of material and design style, makes it possible to implement the most incredible ideas of designers and developers. Trade organizations and manufacturing companies have catalogs of panels that can be installed in the bathroom, with photos and descriptions of their characteristics.The presence of such publications allows you to choose the finishing material you like, even if it is not available at the time of visiting the trade organization.

When selection of wall panels you should pay attention to the following points:

- Workmanship - is expressed in the uniformity of coloring and structure of the material, the presence of defects on the surface and chips, as well as cracks and scratches.

- Geometric dimensions - it is necessary to calculate the required coverage area based on the dimensions of one panel. The calculation is necessary to minimize waste and thereby reduce the cost of the work performed.

- The cost - in different trade organizations the same types of finishing materials cost differently, therefore, before buying, it is necessary to study the entire range of offers on the relevant market in the user's region of residence.

In addition, an important selection criterion is the design of the panels, regardless of the material used and its geometric dimensions. Below are a number of design solutions for decorating a bathroom using various types of PVC panels.

Photo of PVC panels for tiles

Photo of slatted plastic panels

Sheet plastic panels - a photo of some options

Methods for attaching panels to walls

When using various wall panels for finishing a bathroom, the installation work may differ slightly, due to their technical characteristics (dimensions, weight, etc.):

- Plastic products.

This type of panels can be installed in two ways: directly on the wall or a pre-assembled frame. For direct fastening, special adhesives and mastics, as well as liquid nails, are used as an adhesive. In the bathroom, it is preferable to use the second installation option, because in this case, air circulation will be ensured to prevent the formation of mold and mildew inside the building structures. The frame is made of wooden bars or a metal profile, and in the case of using wood, it must be treated with antiseptic materials that prevent decay.

When the panels are arranged vertically, the frame lathing is located horizontally and, conversely, when horizontally arranged - vertically.The lathing step should be 0.4–0.5 m. The panels are fastened with a stapler, construction nails, clips or cleats, and less often with the use of adhesives.

- MDF, fiberboard and chipboard modifications.

These types of panels can be mounted in different ways. The installation method depends on the type and size of the material used. So, rack and sheet models can be installed directly on a wall or frame, and tiled - only on building structures, which is due to the inexpediency of the construction of the latter. For fastening, adhesives, construction nails, clips and cleats are used.

- Acrylic - mounted on the frame using self-tapping screws and then closing them with special plugs.

- Glass - fixed directly to the wall using special fasteners or glue.When installing on the frame, clips and clips can be used.

Related article:

How to fix PVC panels to the wall and ceiling... Useful recommendations of our article will tell you how easy and simple it is to use this material, what methods of fixing the panels are, and also how to perform such work in stages.

How correctly and at what price can you buy wall panels for the bathroom, taking into account the elements for installation

Bathroom wall panels are sold in stores and retail chains that sell building materials and plumbing. In addition to the panels themselves, in such organizations you can purchase additional design elements - plinths on the floor and ceiling, bathtub framing and other products, as well as fastening elements, adhesive compounds and sealants. The following table shows the cost of various types of wall panels that can be used to decorate a bathroom, as of the beginning of the second quarter of 2018, in the Leroy Merlin building materials trading network (the company's online store).

| Material | View | Size, mm | Average price (as of April 2018), rubles |

|---|---|---|---|

| Pvc | lining | 10×100×2000 | 84 |

| leaf | 3×485×960 | 128 | |

| panel | 5×250×2700 | 147 | |

| MDF | moisture resistant | 3×1220×2440 | 1206 |

| 6×1220×2440 | 3500 | ||

| Pvc | angle | 3000 | 10 |

| plinth | 3000 | 25 | |

| profile | 3000 | 32 | |

| Galvanized iron | clips (50 pcs.) | - | 23 |

| kleimers (100 pcs.) | - | 51 | |

| MDF | angle | 2700 | 25 |

| profile | 2070 | 218 |

When buying, you should remember the selection criteria and operating conditions of the selected products, and a large number of various offers on the building materials market and the help of competent specialists will be the key to a successful purchase. The video below will tell you how to finish a bathroom with PVC panels.