Profile for LED strip - purpose and scope

Currently, LED sources are widely used in the life of a modern person, this applies to the device of electric lighting on the street and inside the premises, illumination of buildings, as well as decorating interior elements and individual structures. Designers are quite often for highlighting pieces of furniture or decorative lighting use LED strips due to their good technical characteristics and variety of designs. In order to carry out the installation of LED lamps of this type, special devices are required to ensure reliable fastening of such light sources. Profile for LED strip - its standard sizes and what it is made of, can you do it yourself, as well as an overview of prices and offers in a detailed review of the online magazine homemaster.techinfolux.com/en/.

The content of the article

- 1 What is a profile for an LED strip for?

- 2 What materials are they made of

- 3 Main types of profiles

- 4 Standard geometric dimensions

- 5 Profile for LED strip with your own hands - is it possible to make and how

- 6 At what price to buy a profile for LED strip - an overview of current offers

- 7 Video: “Profile for LED strip. Overview and installation features "

What is a profile for an LED strip for?

The main purpose of a profile for an LED strip is to securely attach this light source to the surface of a building structure, furniture elements or other interior items both indoors and outdoors. Some types of LED lamps have a sufficient degree of protection against moisture ingress, therefore they can be used to illuminate pools and other structures placed in an aquatic environment. In this case, reliable fastening is the key to the successful operation of light sources, and profiles for LED strips successfully provide this condition. In addition, when using out-of-water objects, another purpose of the profiles is to remove heat from the surface of the LEDs generated during their use.

All types of profiles have special shaped elements that are used for their fastening and termination (plugs, strips, fasteners). The surface of the diffusers can be colorless or matte, and the case of aluminum models serves as a conductive core, acts as an anode (anodize the structure).

What materials are they made of

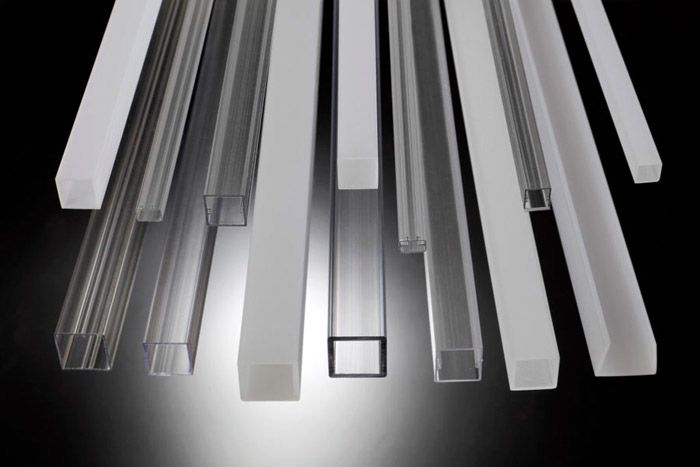

In the manufacture of profiles for fixing LED strips, various types of plastic and aluminum are used. Each of these materials has its own advantages and disadvantages, so about them in more detail.

Plastic Models

In the manufacture of this group of products, polycarbonate and other types of synthetic materials are used. Plastic profiles are lightweight, easy to install and maintain, and, in addition, they have a number of other advantages:

- low cost;

- universality of use;

- elasticity;

- variety of geometric shapes and sizes.

Due to their dielectric properties, plastic profiles cannot act as a conductive core, however, it is this property that allows them to be used in environments capable of conducting electric current, such as water and other liquids.

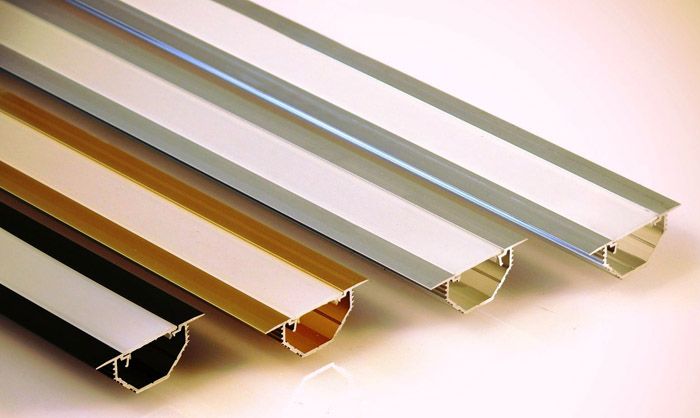

Aluminum models

Structures made of aluminum are durable and not subject to corrosion, which determines the scope of their application. In addition, aluminum looks very stylish, especially in design processing. The industry produces aluminum profiles for LED strips of various geometric shapes, as well as with diffusers made of various materials that improve the lighting characteristics of LED strips.

Main types of profiles

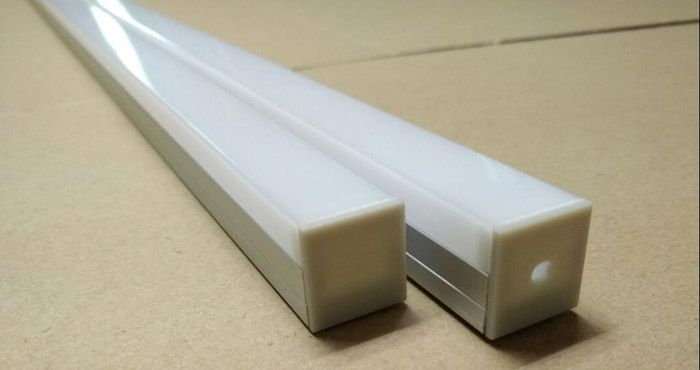

According to their form, which determines the possibility of use, profiles are of several types.

Angular

The corner profile for LED strip can be made of aluminum or plastic. This type of product, as a rule, is equipped with removable diffusers, which is convenient when using lighting equipment. The purpose of this type of profiles is to illuminate surfaces at the mating corners of two perpendicular planes and various structures.

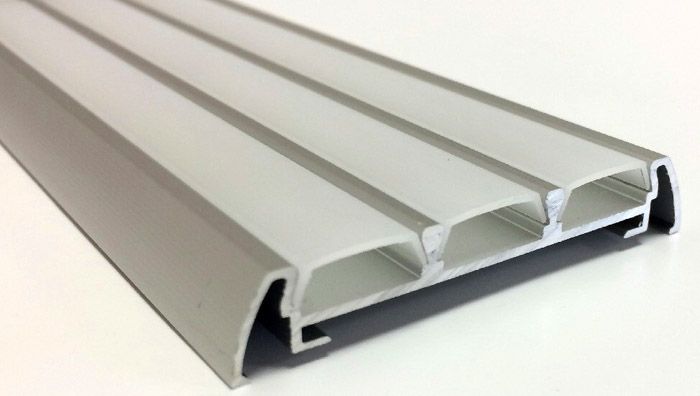

Built-in

The design of the built-in profile assumes its installation inside the surface on which it is mounted. This allows you to hide irregularities in the place of installation of the product, as well as to embody interesting author's ideas of designers. For the installation of structures of this type, it is necessary to carry out preparatory work, expressed in the creation of a groove or opening, into which the built-in profile is mounted, followed by laying the LED strip.

Overhead

This is the most common and universal type of profile due to the simplicity of its installation, which any owner can perform independently. During installation, various types of fasteners can be used (self-drilling screws, furniture nails, etc.), as well as adhesives and mastics. In the manufacture of products of this type, various types of plastic and aluminum can be used. Plastic models are flexible, which allows them to be mounted even on imperfectly flat surfaces.

Flexible

Surface-mounted and built-in profile models made of plastic and aluminum can have a certain plasticity, which allows them to be used on surfaces with complex geometric shapes. Such models are positioned by manufacturers as a flexible profile for mounting LED strips.Plasticity is achieved by introducing special additives during manufacturing, as well as by the geometric shape of the profile surface.

Cable channel

Design cable channelused for mounting LED strips is similar to the design of similar products used for laying electrical wires and cables. Ease of installation and versatility of use are the main advantages of this type of profile.

Related article:

Cable channels. In the publication we will consider the types and sizes of channels, materials of manufacture, criteria for the correct choice, methods of use, an overview of manufacturers and models, recommendations of specialists.

Standard geometric dimensions

Various types and models of such products are produced by manufacturers of different geometric sizes, but one condition inherent in all of them is the possibility of placement in their internal spaceLED light sources.

The industry produces LED strips of the following section:

- The usual type of glow:

- width - 8-13 mm;

- thickness - 2.2–5.5 mm;

- length - up to 5 m.

- Side glow type:

- width - 6.6 mm;

- thickness (height) - 12.7 mm;

- length - up to 5.5 m.

The geometric dimensions of different models from different manufacturers differ from each other, but the most common ones are shown in the following figure.

Profile for LED strip with your own hands - is it possible to make and how

Due to the availability of purchasing LED strips, their good technical characteristics in terms of energy saving, as well as the possibility of creating an individual style using them, the question of self-production of a profile for their installation is quite relevant for many users. The main conditions for the successful manufacture of a profile with your own hands are: the availability of free time, the ability to think creatively, as well as the ability to work with hand-held locksmith tools.

Firstly, for the manufacture of a profile, which serves as the basis for the subsequent installation of LED strips, electrical cable channels, which are widely represented on the market of electrical products, can serve. In this case, the cable duct is mounted as when laying electrical and low-current wires, and the LED strip is laid in its inner space. In this case, the cover of the cable channel does not need to be installed, and as a diffuser, you can use a decorative film or do without it altogether. Another option is to use electrical plinth or decorative, equipped with a channel for laying wires and cables.

Installation of such elements is carried out in accordance with their intended purpose, and the LED strip is laid in the inner space of the channel available on the plinth.

With a detachable design of the product, the removable part is removed, and, as in the case of using an electric cable channel, a decorative film or other transparent material fixed to the surface can serve as a diffuser. skirting boards... In the case of using one-piece products, it is necessary to cut the outer surface of the plinth, thereby ensuring the penetration of light emitted by the source into the interior space of the room, as well as ensuring the removal of heat generated by the LEDs during operation.

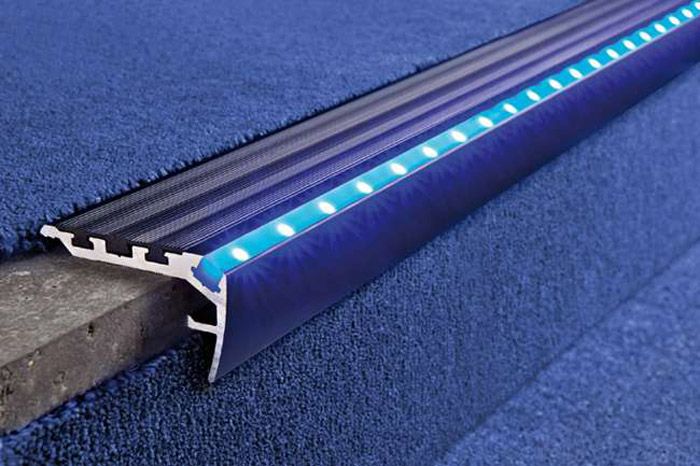

When to backlight stairs or other building structures on which special elements with voids (slots, cracks, etc.) must be installed, then in these places it is also possible to lay LED strips. In this case, it may be necessary to expand the existing voids, after which they can be used as profiles for mounting lighting and decor elements. When performing backlighting in the corners of building structures or furniture and interior items, you can use plastic or aluminum construction profiles, which are used for finishing work, to mount LED strip. In this case, they are mounted in the place of intended placement using fastening elements suitable for these purposes. An LED strip is used, which has an adhesive base, with which it is attached to the used building profile.

Thanks to the adhesive backing, the LED strip can be attached directly to the surface of building structures and decorative elements

Related article:

In this article we will talk about how wiring diagram of 220V LED strip to the network... You can install such a structure yourself. And we will help you with this.

At what price to buy a profile for LED strip - an overview of current offers

Profiles for the installation of LED strips are sold in stores and retail chains that sell lighting products, as well as electrical materials. In addition, such products can be bought on the Internet, where a large number of companies operating in this market of goods are also represented. The following table shows the price for different types of profiles, as of the beginning of the II quarter of 2018, when selling products via Internet resources:

| Trade company | Material | Profile view | Model | Geometric dimensions (width × length), mm | Average cost (as of April 2018), rubles |

|---|---|---|---|---|---|

| www.ledformula.ru | Aluminum | Overhead | "SlimLine 10" | 36,6×2000 | 1722 |

| "SlimLine 20" | 20×2000 | 3600 | |||

| "PowerLine" | 80×2000 | 6688 | |||

| Built-in | "SlimLine 8" | 18×2000 | 1490 | ||

| "HR-2000 ANOD" | 19,2×2000 | 445 | |||

| "U-S35-IN" | 35×2500 | 2680 | |||

| Angular | "KLUS-LOCK-FM-2000 ANOD" | 9,2×52×2000 | 529 | ||

| "KLUS-P45-2000 ANOD" | 17×42×2000 | 930 | |||

| "ALU-45" | 18×55×2000 | 2740 | |||

| www.spb.shopleds.ru | Plastic | Overhead | "WPH-LINE-1212-2000 OPAL" | 12,2×2000 | 424 |

| Flexible | "WPH-FLEX-STR-Н20-5000" | 8,9×5000 | 1447 | ||

| Angular | "WPH-KANT-H10-2000 OPAL" | 10,3×10,2×2000 | 358 |

The price of a profile for an LED strip and its range offered for sale depend on the place of purchase, therefore, when deciding whether to purchase such products, it is better to contact large organizations specializing in the implementation of electrical and energy saving products.

In a sales organization, you can touch the product you like with your hands and get detailed information from a sales assistant

The abundance of such offers on the market allows you to choose products of the required standard size and in accordance with the financial capabilities of the user.