Noise insulation of the floor in the apartment - device features for different types of bases and floor coverings

In modern living conditions, it is difficult for the majority of the population to isolate themselves from the outside world in an apartment in an apartment building. This is due to the fact that during the construction of apartment buildings, the issue of sound insulation is not in the first place, since the use of new technologies and materials that can absorb external noise leads to higher construction costs. Often you have to deal with the soundproofing of your home on your own. Soundproofing the floor in an apartment, device features for different bases and types of floor coverings, a review of prices for the most demanded ones, as well as leading manufacturers of the materials used - the topic of this article in the online magazine homemaster.techinfolux.com/en/.

For high-quality sound insulation, it is necessary to think over this issue even at the stage of construction work in relation to all enclosing structures (walls, interfloor ceilings, etc.)

The content of the article

- 1 Modern materials for soundproofing the floor in the apartment

- 2 Leading manufacturers of floor sound insulation

- 3 Features of soundproofing the floor in the apartment from the neighbors below in accordance with the material of the floor covering

- 4 Optimum sound insulation for different types of subfloors

- 5 How to make floor soundproofing in an apartment

- 6 How much do soundproof flooring materials cost - price overview

- 7 Video: floor sound insulation, material comparison

Modern materials for soundproofing the floor in the apartment

Sound insulation (noise reduction) is measures that allow to reduce the level of noise penetrating from the outside into the inner space of a room, structure or vehicle by using special materials - both during the manufacture of the product and the performance of construction and installation works, and upon their completion during the repair period ...

Currently, three types of materials are used for soundproofing the floor: soundproofing membranes, roll and plate products.

Important! When using any of the sound-insulating materials when performing installation work, it is necessary to follow the manufacturer's recommendations for the method of their application and installation, which will ensure the specified indicators of protection against the penetration of external noise into the inner space of the insulated room.

The sound insulation quality of the insulated room depends on the correct technology for performing work.

Sound insulating membranes

The following materials are used as a soundproof membrane mounted on the base of the floor:

- plywood and other board materials made from woodworking waste (Fiberboard, Chipboard, MDF);

- thick cardboard;

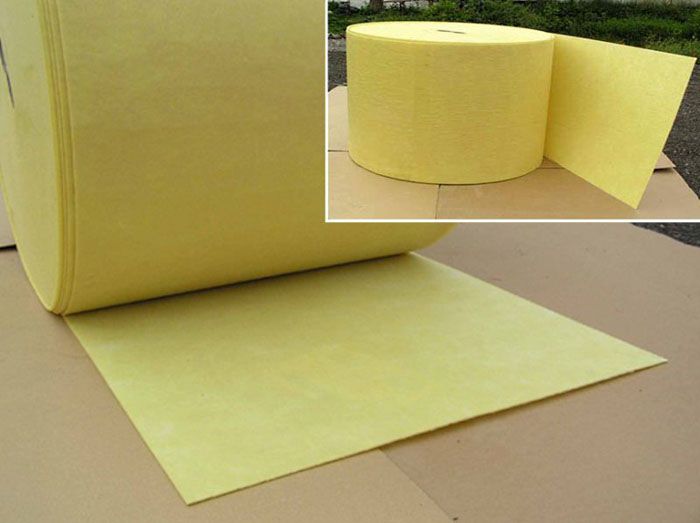

- special types of fabric - felt of various types (technical, acoustic and with a built-in membrane);

- special soundproofing membranes made from polymeric materials and natural fibers using binders.

The most widely used materials for sound insulation are felt and special membranes. Their advantages are:

- small thickness, which makes it possible to slightly reduce the internal volume of the room where they are mounted;

- high density;

- ease of use (cutting, styling);

- elasticity;

- there are modifications equipped with a self-adhesive layer, which simplifies the installation process;

- can act as a heat-insulating material;

- long service life.

Among the disadvantages of membranes, it should be noted:

- high cost;

- the need for thorough preparatory work to create a flat surface of the base on which the installation is performed.

Roll version of soundproof material

In the form of rolls, manufacturing companies produce the following types of soundproofing materials:

- "Vibrostek-V300" - is made on the basis of "C" class fiberglass and can be used as a substrate when installing floor coverings;

- "Maxforte" - can be mounted under the topcoat and under the screed, and also act as a waterproofing;

- "Soundproof" Is a bitumen-polymer material that can also act as waterproofing.

Board materials

This category of materials is especially popular among developers, which is associated with the simplicity and convenience of performing installation work with their use.

The most demanded in this group are:

- mineral wool - differs in versatility of application and non-flammability. The negative properties include hygroscopicity;

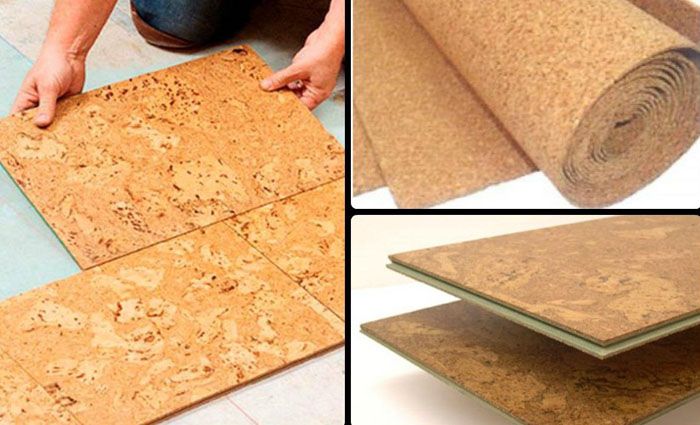

- cork panels and tiles - they are environmentally friendly products, but require care when performing installation work, as they are easily destroyed when exposed to "rupture";

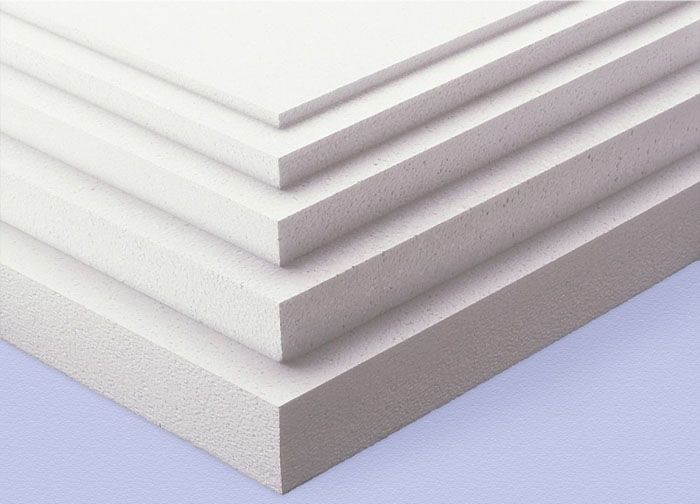

- expanded polystyrene - quite popular material due to its relatively low cost;

- fiberglass panels "SHUMANET";

- Izoplat - insulating panels made from woodworking waste.

Related article:

Noise insulation of walls in the apartment: an overview of modern materials, their advantages and disadvantages, advice and recommendations of experts - read in our publication.

Leading manufacturers of floor sound insulation

On the domestic market of building materials in the segment of soundproof products, products of foreign and Russian companies are sold, the most popular among users are:

- MaxForte, TechnoNicol, TechnoSonus and AcousticGroup (Russia);

- WolfBavaria (Germany);

- Texdecor (France);

- Rockwool (Denmark);

- Mappy (Italy);

- IsoverEcophon (Sweden - Finland);

It is always possible to choose the right material in the right price range and in accordance with the purpose and nature of use

Features of soundproofing the floor in the apartment from the neighbors below in accordance with the material of the floor covering

Depending on the type of floor covering, one or another soundproofing material is chosen, therefore different types of such products are mounted in different ways.

Soundproofing the floor under the laminate

Laminate is a wood fiber based flooring and requires a flat surface for installation.Before laying the laminate, a substrate is always laid, which hides the remaining irregularities on the surface of the base and helps to distribute the loads over its surface.

The substrate can also perform the function of sound insulation, therefore, in this capacity, as a rule, cork materials and Isoplast are used, and for flooring in humid rooms - "Soundproof".

Soundproofing floor under linoleum

Using linoleum Various types of sound-insulating materials can be used as a finishing floor covering, while the main condition for their use is their strength and ability to withstand mechanical loads.

The most popular for this type of coating is "Soundproof", which is associated with its physical qualities (moisture resistance and strength), as well as low thickness.

The use of "Zvukoizol" allows you to simultaneously perform waterproofing and sound insulation of the sub floor

The best floor sound insulation for ceramic tiles

Porcelain stoneware is generally used as a floor covering in bathrooms and showers, as well as in kitchens and other areas where high levels of humidity are present.

As a sound-insulating material for ceramic tiles, they usually use "Soundproof", "Maxforte", "SHUMANET" and "Vibrostek-V300".

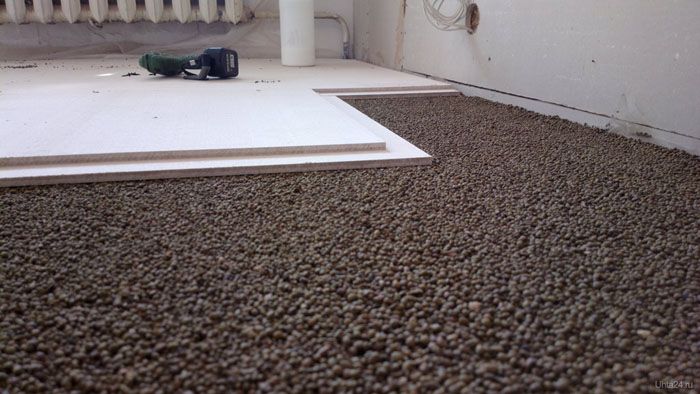

Note! Extruded polystyrene and expanded clay can be used as sound insulation when laying porcelain stoneware. After filling them, it is necessary to fill the leveling screed.

Making a concrete screed on the surface of expanded clay, which serves as a sound-insulating and heat-insulating material

Soundproofing wooden floor

The choice of soundproofing when laying a wooden floor depends on its construction and the height of the ceilings in the room where the work is performed.For low ceilings, the same materials can be used as for laminate insulation.The most common option, given sufficient headroom, is to use mineral wool between the joists on which the wooden floor is laid.

Related article:

Noise insulation of the ceiling in the apartment under a stretch ceiling: varieties, step-by-step installation instructions, advice and recommendations of specialists - read in our publication.

Optimum sound insulation for different types of subfloors

The choice of material used as sound insulation is influenced by both the finishing flooring, as described above, and the type of base on which it is laid.For different types of base, the circuits of the noise isolation device are different, so they should be considered separately.

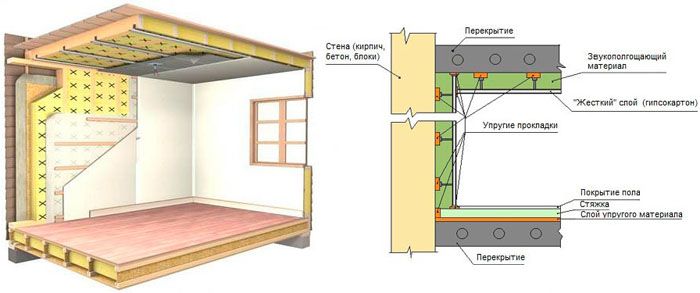

Soundproofing the floor in the apartment under the "floating" screed

Note! A floating screed is a special way of laying the floor covering without rigidly fixing the materials used to the building envelope (walls, ceilings).

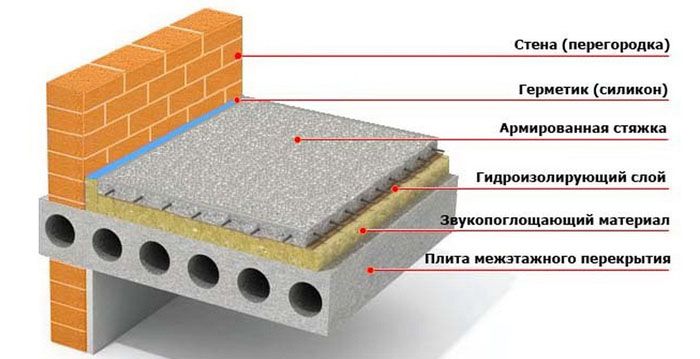

The floating screed is made on top of the sound-proof layer, which can be used as such materials: special types of membranes and mineral wool, cork products and expanded polystyrene.

A diagram of the "floating screed" device is shown in the following figure:

Soundproofing the floor in the apartment on a dry and cement screed

In some cases, soundproofing the floor in the apartment can be done by installing a dry screed.With this option, the use of water and aqueous solutions is excluded.

Perlite, expanded clay or vermiculite are used as sound insulation, which are poured onto the surface of the interfloor overlap, and plywood or other board material is laid on top of them.

Note! When performing a dry screed, other roll and sheet materials can be used as sound insulation.

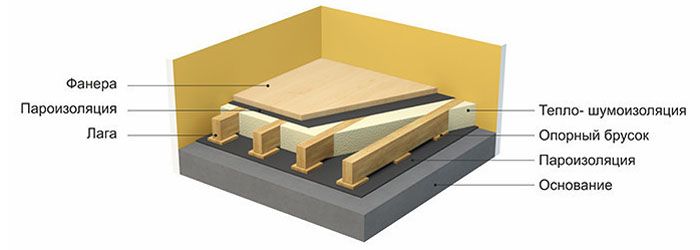

The dry screed scheme is a "cake" laid in the following sequence: base → vapor barrier layer → sound insulation layer → leveling layer (plywood, etc.) → waterproofing → floor covering.

When installing a screed using cement mortars, this option for performing work is called a semi-dry or wet screed.In this case, materials that are resistant to moisture are used for the construction of a soundproof layer: expanded clay, expanded polystyrene or "Soundproof".

Related article:

In solving the problem of a crooked floor will help dry floor screed... Pros and cons, reviews, the price of this type of coating, styling features and specialist recommendations are in this material.

Sound insulation of frame floor on joists

As mentioned above, wooden floors are mounted on the logs. In this case, various types of slab, roll and sheet materials are used as sound insulation, laid between the logs.

The scheme of the device of such a cake also includes steam and waterproofing, a leveling layer (plywood) and finishing.

How to make floor soundproofing in an apartment

It is better to entrust the installation of sound insulation in an apartment to professionals, however, if desired, they can be performed independently.

When doing work on soundproofing the floor with your own hands, you must:

- Decide on the type of soundproofing material used and calculate the amount required to perform the work.

- Prepare the necessary tools and fixtures.

- Prepare the basis for the work.

Important! The base on which it is planned to install the sound insulation must be cleaned of debris and dust, and, if necessary, leveled.

To carry out work with different soundproofing materials, a different tool is required, therefore its list is determined individually in each specific case.

Materials for soundproofing the floor in the apartment are determined individually, based on the need and financial capabilities

How much do soundproof flooring materials cost - price overview

The cost of soundproofing flooring materials depends on the place of purchase, the brand of the manufacturer and the components from which they are made.The following table lists the retail prices for some of the products discussed in this article.

The price of soundproofing materials for the floor is indicated as of the third quarter of 2018.

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Membrane | MAXFORT-SOUNDPRO | Length - 5.0 m; Width - 1.4 m; Thickness - 12 mm. | 1090 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Membrane | Texound 70 | Length - 5.0 m; Width - 1.22 m; Thickness - 3.7 mm. | 1430 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Membrane | Soundguard Membrane 2.0 | Length - 2.5 m; Width - 1.2 m; Thickness - 2.0 mm. | 545 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Roll | Vibrostek-V300 " | Length - up to 450 m; Width - 1 m; Thickness - 3 mm. | 290 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Roll | MAXFORT SHUMOIZOL | Length - 10 m; Width - 1 m; Thickness - 4 mm. | 290 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Roll | Soundproof | Length - 15 m; Width - 1 m; Thickness - 4 mm. | 187 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Slab | MAXFORTE-ECOPLITA | Length - 1.0 m; Width - 0.6 m; Thickness - 3 cm; The number of plates in the package is 5 pieces. | 420 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Slab | MAXFORTE-ECOPANEL | Length - 1.2 m; Width - 0.8 m; Thickness - 1.2 cm | 790 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Slab | Noise stop | Length - 1.25 m; Width - 0.6 m; Thickness - 2.0 cm | 245 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Slab | NOISE | Length - 1.25 m; Width - 0.6 m; Thickness - 5.0 cm | 260 |

| A type | Brand | Specifications | Average cost (as of August 2018), rubles |

|---|---|---|---|

| Slab | "StopSound" (basalt) | Length - 1.25 m; Width - 0.6 m; Thickness - 5.0 cm | 274 |

The variety of different materials allows you to choose the sound insulation you need for the device in accordance with the requirements for it and in the selected price range.

Video: floor sound insulation, material comparison

Sometimes it is difficult for an unprepared user to select the desired material, so our editorial staff provides the following video: