Prefabricated metal racks: organization of a warehouse without unnecessary costs and mistakes

It is not difficult to efficiently use the available free space for storing various things. Prefabricated metal racks are well suited for this. Such designs are used in trading and manufacturing companies, offices and apartments. With the help of this article, it will be easier to correctly implement the corresponding project with minimal costs.

The content of the article

- 1 How prefabricated metal racks are used: purpose, formulation of personal preferences

- 2 The design and characteristics of individual parts of metal shelving for the home

- 3 Types of metal shelving

- 4 Features of Metal Prefabricated Warehouse Racking

- 5 Making metal shelving for a garage: step by step instructions

- 6 Where to buy metal shelving

- 7 Catalogs, market overview, reviews

- 8 Conclusion with additional recommendations

- 9 Video: racking assembly

How prefabricated metal racks are used: purpose, formulation of personal preferences

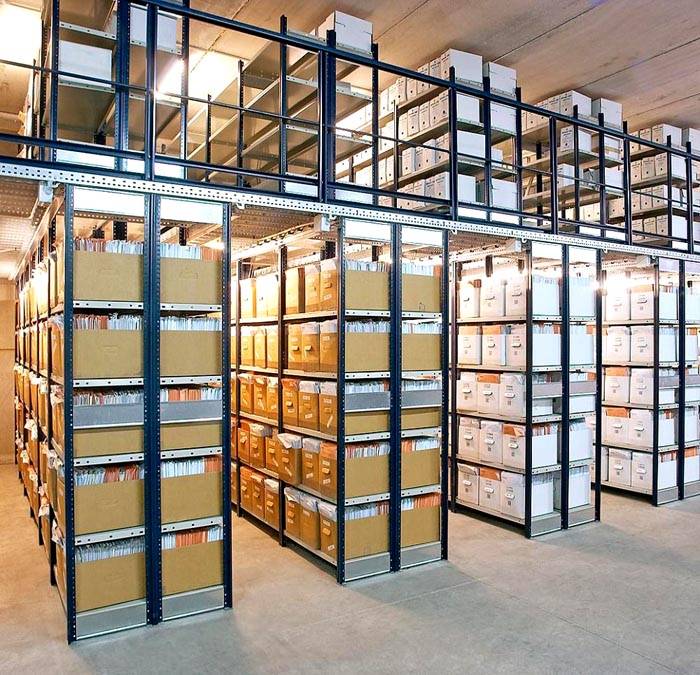

In such facilities, prefabricated metal racks are a relatively simple part of the overall project. For high-quality storage of certain things, an optimal mode is maintained. Moving products is carried out using specialized lifting equipment. Software is used to optimize logistics. Some operations are performed using automation tools.

For storage of small products, prefabricated metal warehouse racks will be supplemented with special containers

The dimensions of the boxes determine the distance between shelves, support beams. Labels with markings will be used to simplify the search.The height of the structure is limited by the parameters of the room. Please note that the calculation must take into account the placement lamps, other items of equipment.

Here, prefabricated metal racks are used to store operational stocks and present goods to potential buyers. The distance between the shelves is selected so that you can easily take the product you like. The end parts are equipped with transparent overlays for placing price tags.

In such premises, conditions change greatly during operation, when performing routine sanitary and hygienic procedures. If you make shelves out of wood, they will quickly deteriorate. The impregnation of such products with protective compounds is not permissible, since food is stored here.

Archival metal prefabricated heavy racks are equipped with special mechanisms that facilitate movement

This equipment allows the passageways to be cleared as needed. This solution helps to economically use the available workspace. But at the same time - it significantly increases the cost of the structure. Built-in padlocks provide reliable protection against illegal actions.

The options shown are industrial and commercial. But this article will focus on household projects. Nevertheless, it is professional solutions, together with the nuances noted above, that will help to more accurately formulate the requirements for a collapsible metal shelving for the home:

- Formulate the exact problem to be solved. If a purely utilitarian application is intended, there is no point in overpaying for a perfect appearance.

- Check the weight, dimensions, special characteristics of things. Consideration should be given to optimal storage conditions. Some products should not be placed near heating appliances, in direct sunlight.

- Next, they study the architectural features of the premises. It should be noted that prefabricated metal shelving can be very precisely "tailored" to the configuration of a particular room.

Based on the information collected, a final list of the required characteristics of a prefabricated metal rack is compiled. Next - create a package of project documentation.

The design and characteristics of individual parts of metal shelving for the home

In addition to the drawing with dimensions, you will need to calculate the loads. This drawing can be used to compile a list of required parts. It will also come in handy when looking for suitable ready-made sets of factory production.

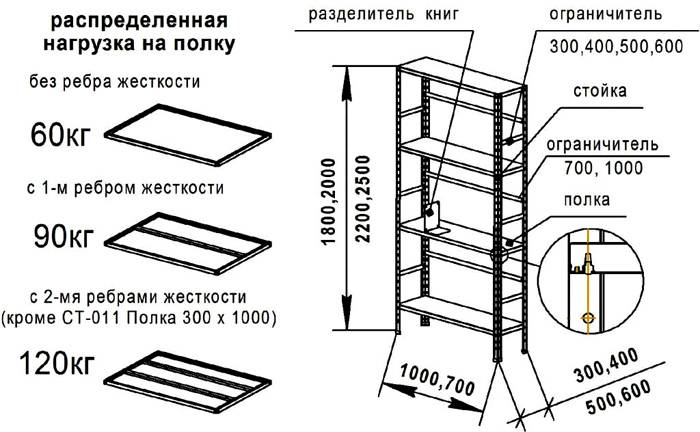

Choosing metal racks for shelving

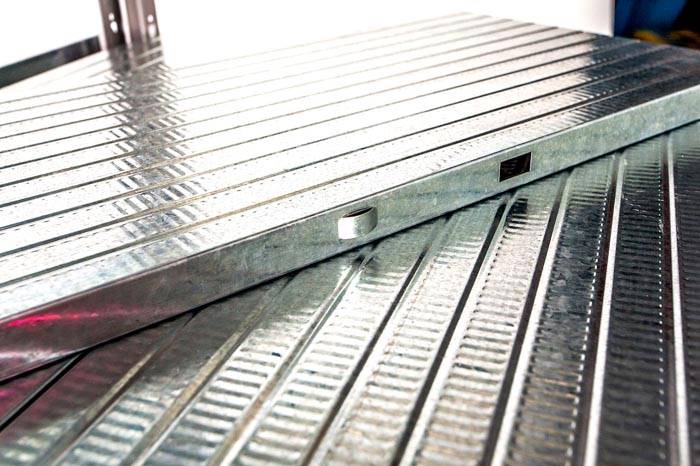

Such manufactured products are protected against corrosion by multi-layer coatings: zinc, primer, paint. The set includes special polymer pads that prevent scratches. Pay attention to the intricate relief of the faces. The created stiffeners increase the strength of the supporting parts of the prefabricated metal rack.

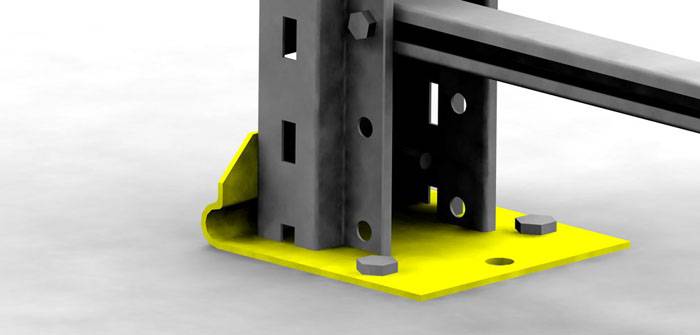

They protect the uprights of the prefabricated metal rack from accidental damage by loading vehicles. At home, such precautions are unnecessary. However, they can come in handy when equipping the garage.

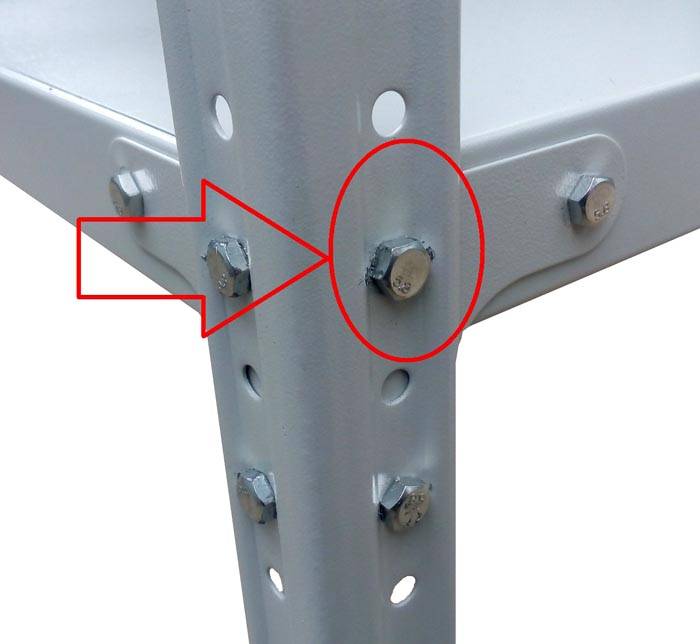

This photo demonstrates not only the correct installation method, but also an insufficiently accurate assembly. The use of screws and nuts without soft gaskets and washers will damage the protective and decorative coating. Even in a room with normal humidity levels, unsightly traces of rust quickly form on such a surface.

In this embodiment, the holes are drilled in exact accordance with the drawing. The surface is cleaned, fat is removed. Coated sequentially with a primer and paint. Create multiple layers for better protection.

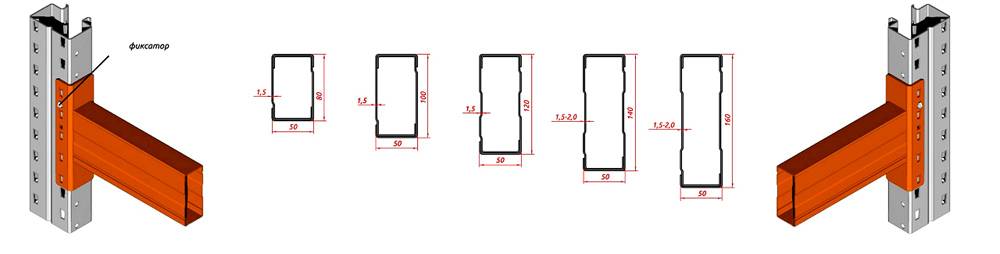

Suitable racking beams: structural features

Such products are installed in reinforced metal racks, which are designed to store products on pallets.

Note! Self-made cross beams can be made from strips, corners, pipes, and other standard metal products. In any of the options, the permissible loads must be correctly calculated. Pay special attention to connections. If necessary, install additional corner and vertical supports.

What is the best shelving flooring? Correct answers to practical questions

The exact choice of material depends on the parameters of the things that will be placed on the shelves.

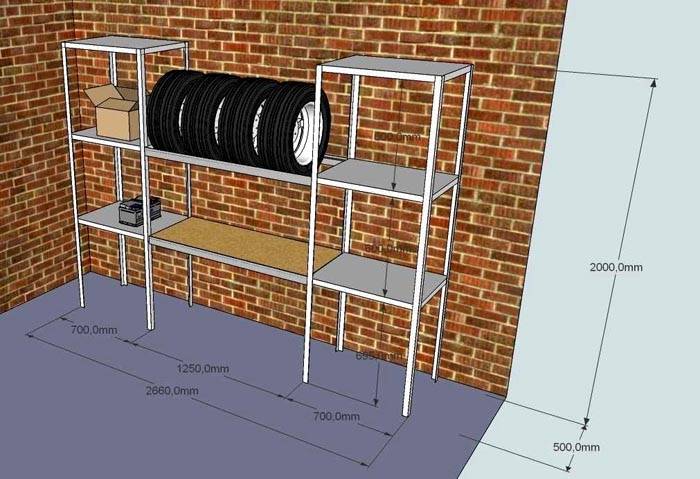

As shown in the figure, the vertical position is used to properly store the wheels. The flooring is not needed in this case. Here you just need to install suitable cross members, without sharp edges. This will prevent damage to the tires. It is better to place a sheet of metal from below instead of chipboard. It is easier to remove dirt and moisture from it.

Plain plywood: "cheap and cheerful"

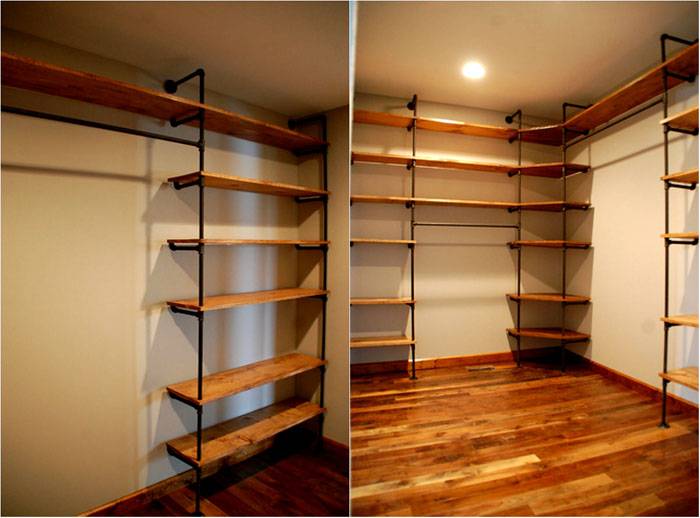

The section title uses a symbol. In fact, we are talking about a similar solution. Here the power frame is made of durable metal. And the shelves are made of materials that are easy to handle. Below are the features of different products.

The most inexpensive options are Chipboard, Fiberboard... These boards have limited resistance to mechanical stress. They are distinguished by the worst aesthetic characteristics, solid weight. Such surfaces absorb oils, other dirt, and odors. They are difficult to clean. Insufficient quality products in this category worsen the state of the atmosphere in the room with harmful chemical compounds.

With a layer of lamination, the appearance of chipboard and fiberboard improves, but the price increases significantly. Such products are used for the manufacture of window sills, therefore, adhesives that are harmless to human health are used.

Sanded and film faced plywood looks best. Currently, products are produced with different impregnations, which improve resistance to high temperature, humidity, and decay.

In this version, we are talking about complete furniture. To equip the warehouse, inexpensive boards can be used, which are laid laterally to increase the strength on the beams from metal corners.

Important! The main advantage of all wood products is simple processing. Many operations can be performed independently using a hand tool. The main disadvantage is low resistance to adverse external influences.

Many parts of one of the finest WWII fighters are made of wood. As you can see, when used correctly, parts made of this material can withstand extremely high loads.For completeness, examples should be given with plastic shelves.

Polymer shelves in prefabricated metal racks are highly resistant to moisture, lightness. In some situations, a variety of colors and permanent structural stains are useful. Main disadvantages:

- high price;

- low resistance to high temperatures;

- relatively low strength.

Metal flooring for the "bunker"

The reliability of steel is useful not only for equipping secret bunkers. Products made of this material are able to withstand significant loads without damage and deformation for a long time.

In any case, the metal is protected from destructive corrosion. In addition to the direct application of special layers, preventive measures are used. To eliminate excess moisture, ventilation and heating are installed.

The main disadvantage of this material is the complexity of processing. Straight cutting, drilling and other simple work steps can be done with hand tools. Basic knowledge and skills will be required. However, it is more difficult than from wood to create parts of a complex shape. For high-quality welded joints, not only special equipment is needed, but also sufficient qualifications.

Selecting additional items

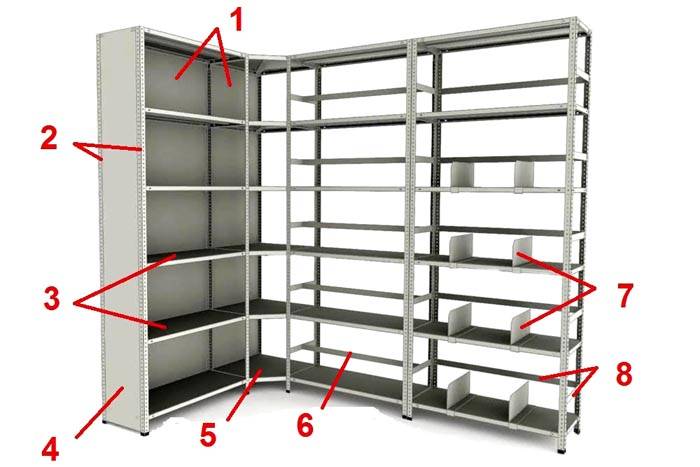

The figure marked:

- back (1) and side (4) walls;

- racks (2);

- standard (3) and corner (5) shelves;

- longitudinal reinforcing elements (6) for placing heavy objects on the corresponding flooring;

- dividers (7) for the shelves of the prefabricated metal rack;

- additional horizontal strips (8), strengthening the load-bearing frame.

These thrust bearings can be adjusted in height. They are used for precise alignment of structures on uneven floor coverings

In this modification of the base plate, holes are made. With the help of anchors, rigid fixation of the racks is provided

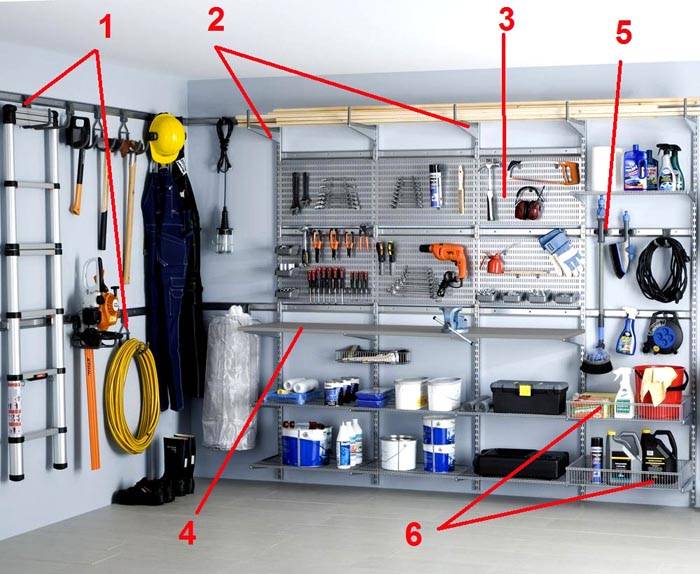

This photo explains how a multifunctional structure can be created using special additional elements:

- Large hooks (1) are installed at different levels. Ladders, tools, clothes, cables are hung on them. To simplify maintenance, the wall in such places is covered with high-quality washable paint. The second option is the installation of a protective wall made of metal, plastic, or other suitable material.

- Such horizontal supports (2) are used to store sawn timber, corners, rods and other long products.

- Hooks and boxes with hooks on the side faces are inserted into the perforated plates (3). Such devices are used to store small items.

- When choosing suitable supports and flooring in such a place, you can make a full-fledged work table (4), a workbench.

- The latch clamps (5) are selected taking into account the size of the inventory handles.

- Baskets with walls (6) are placed in the right places.

Types of metal shelving

After studying the main and additional components, materials, you need to move on to the study of structures. There is no point in “reinventing the wheel”. This section presents solutions that have successfully stood the test of time. You can buy the appropriate products, or apply the ideas of professionals to make a prefabricated metal rack with your own hands. In any case, do not forget about the purpose of your own project.

Mobile shelving: flexible configuration and other benefits

Products in this category are used to equip warehouses and archives. Prefabricated and welded structures are used. To move large heavy parts, strong rail systems are built into the floor, mechanical and electrical drives are included in the kit.

Independent creation of such products in a home workshop is not economically feasible.

The method of fastening such parts does not restrict turning in either direction. Rubber pads provide a smooth ride, do not create scratches on the floor surface. Built-in clamps prevent movement after the structure is installed in the working position.

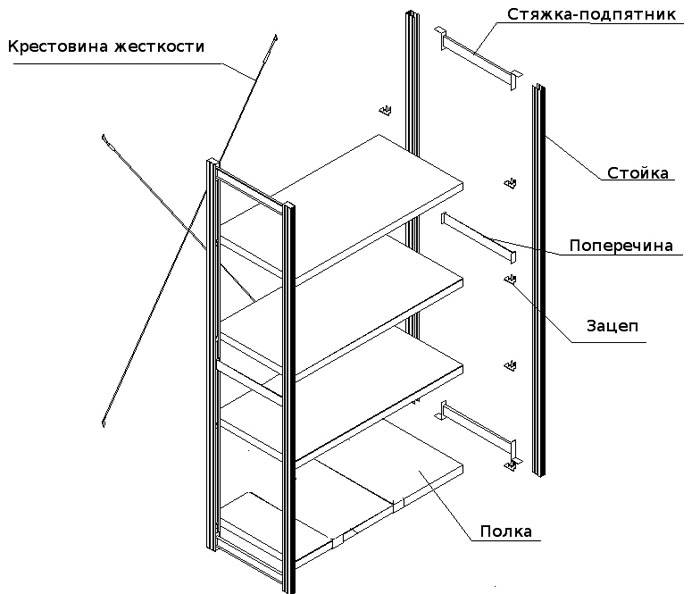

Racks on hooks

One of the most important advantages of such products is the absence of connections using screws, bolts, and other standard fastening materials.

This feature implies high speed and ease of assembly. Large items are not lost during transportation. No special tools are required for installation. Frequent perforations allow you to quickly select the desired shelf height.

An additional "plus" is the ability to quickly modify the warehouse structure for optimal organization of storage of other things, taking into account certain sizes. If necessary, the prefabricated metal rack can be easily dismantled and moved to another place.

Using standard accessories, it is not difficult to change the length and width as needed. However, it is imperative to remember about the load capacity. These data are indicated in the accompanying documentation by the manufacturers. So, for example, the weight per frame is limited taking into account the following features of the prefabricated metal rack:

| Options | The values | ||||

|---|---|---|---|---|---|

| Distance from floor level to lower cross member (flooring), cm | 300 | 500 | 700 | 900 | 1000 |

| Permissible load on one prefabricated block, kg | 1700-1800 | 1500-1650 | 1250-1300 | 900-950 | 650-750 |

It is recommended not to reduce the distance between the following shelves in order to maintain the stability of the prefabricated metal rack. In some cases, standard distances are indicated, in others - the minimum number of transverse elements for a certain height. To prevent damage during operation, the loads should be distributed with decreasing height, evenly - horizontally. It is necessary to exclude shocks and other lateral mechanical influences.

Note! To strengthen the structure of the prefabricated metal rack, diagonal and transverse ties are used. Use additional fastening to the floor, ceiling, walls, and other architectural elements in the room. Choose sufficiently strong, reliable and safe supports. Connection to gas mains, electric cables and water pipes for solving such problems is not permissible.

Shelf versatility

These structures are used to equip household facilities and commercial warehouses. They are designed to equip various storage facilities where manual cargo handling techniques are expected to be used.

Factory universal products of this type are offered as a set of standard elements. They can be used to assemble the required configuration quickly and without errors. This approach implies the possibility of simple modernization, no problems during assembly, and affordable cost.

The shelves are supported directly by uprights, transverse or longitudinal beams. To strengthen the prefabricated metal rack, stiffeners, additional elements, and fastening to architectural structures are used.

This kit includes flights of stairs, handrails and all second floor floor components.

Reinforced shelving: a safety margin for tough tasks

Pallet storage is used for handling heavy loads. In such situations, the means of mechanization are widely used

In such modifications, the flooring is formed from a large number of rollers. The shelf is installed at a slight slope. When lowering the fixing side, the load begins to move independently under the influence of gravity. Provides greater storage depth and eliminates the cost of powering the drives. The simplicity of the solution is accompanied by improved reliability.

To increase the load capacity, the corresponding parameters of individual structural elements are improved

Additionally, fixation is applied to parts of the structure. Prevents excessive mechanical stress during use.

Prefabricated / collapsible metal racks

Shelf storage systems can be created in a stationary design for increased durability. However, a detailed acquaintance with consumer characteristics allows us to make sure of the advantages of collapsible metal racks:

- with the right choice of design and individual components, a connection with the required strength will be provided;

- personal vehicles are suitable for transportation of prefabricated metal rack parts. If necessary, you can rent a trailer, roof rack;

- high-quality installation is performed independently, without assistants and expensive professional services;

- the structure can be modified, removed, moved from an apartment to a dacha or to another place.

The prudent owner will love the residual value of the purchased parts. You can sell them as a set or individually. Stationary products are highly specialized, which implies relatively low demand.

Features of Metal Prefabricated Warehouse Racking

To make the right choice, you must carefully study the future use of the structure. Heated residential areas, for example, do not need enhanced corrosion protection. When equipping a cold warehouse in which seasonal items are stored, the value of this parameter increases.

Careful inspection will help you find the truly best prefabricated metal shelving from the many alternative offerings on the market.

The following important details are noted on the photo of a standard shelf:

- Sharp corners (1) have been removed by the manufacturer to improve safety during installation and normal use.

- A quality coating (2), applied using industrial technologies, provides reliable and durable protection against corrosion.

- This lightweight product (3) will withstand a high load, up to 150 kg per shelf with an even distribution of the load. The corresponding data are indicated officially in the technical passport. They can be used to accurately calculate the overall design of the prefabricated metal rack.

- Correctly selected hardware (4) is easy to work with. They don't overreact. They can be tightened using any standard tool and improvised means.

- Quality perforation (5) is suitable for bolting to the posts.

- Special holes (6) with frequent spacing are intended for mounting cross dividers, hooks, fences, and other accessories.

- These ribs (7) increase the rigidity.

- The sufficient strength of the shelf is explained by the use of a steel sheet with a thickness of 0.7 mm (8).

Making metal shelving for a garage: step by step instructions

In the following example, metal prefabricated garage racks are made of lightweight aluminum profile. It is easier to work with such blanks, but it is necessary to select the right products to ensure compliance with the operating loads.

Where to buy metal shelving

Consider carefully the technology of self-manufacturing products. You will find that quality prefabricated warehouse racks are not easy to create. To make a one-piece steel frame, you need to purchase and master special equipment.

Of course, you can use smoked glass and old dirty clothes. But in this case, the risks of damage to the retina of the eyes will be excessively increased. In the worst situations, complete loss of vision threatens. If you do not plan to open your own metal workshop, such investments in high-quality equipment are clearly unnecessary.

The second option is easier. However, in this case, you must use a special tool to create blanks. Less durable aluminum is not able to provide high resistance to stress. We have to purchase large, rather expensive profiles.

For an accurate cost estimate, summarize the following items:

- Independent calculation of the structure of a prefabricated metal rack, drawing up a project.

- Purchase of initial blanks, consumables, fasteners, tools, replaceable devices, personal protective equipment.

- Independent visits to different stores and personal delivery of goods to your home.

- Mastering technological processes with training costs, marriage.

- Execution of working operations.

- Correcting mistakes, re-visiting stores and repeating the operations done until the desired result is obtained.

Note! The complete absence of guarantees should be noted separately. If a "wonderful" creation of your own hands falls to the floor along with expensive Christmas tree decorations, you will have to compensate for the losses yourself.

Are there any alternative solutions? Of course! Using the Internet, you can quickly find out the addresses of the nearest specialized workshops. It will not be difficult to find a company that will make prefabricated metal warehouse racks on an individual request. The price in this case will be fixed in a formal contract. They also indicate the terms of payment and delivery, terms, penalties, warranty obligations. In this case, it is possible to determine precisely the amount of investment required, personal time and labor costs.

Catalogs, market overview, reviews

Another convenient way is to buy cheap prefabricated metal shelving. At the very least, this will significantly speed up the implementation of plans. Check out this table first.

Here are the current offers from specialized manufacturers. The prices of prefabricated metal racks change with the market conditions. However, these data are quite suitable for comparative analysis, general understanding of the situation, and study of new products.

Feedback from owners and users is also useful:

Mad_Panda: Pluses: Large, metallic. Assembling a metal rack is very simple. The only thing that needs to be collected is where it will stand or where there is a lot of space. Quite voluminous, but not heavy.

Disadvantages: Could have put in spare bolts.

More details: http://irecommend.ru/content/otlichnaya-veshch-stoit-na-balkone-na-nem-pomestilos-srazu-vse

Jasemin: Features and Benefits: In principle, it looks like a normal "garage" version, but in the right hands it can turn into a stylish addition to almost any interior. You can adjust the height of the shelves, which gives space for creativity and expression of stylistic solutions.

Disadvantages: Not identified.

More details: http://irecommend.ru/content/stilnoe-resheniem-dlya-khraneniyastellazh-dlya-khraneniya-ikea-omar

Buying finished products not only saves time. This method allows you to purchase a prefabricated metal rack with certain technical characteristics. The official guarantee is valuable enough. With the best of luck, you can get a great set with big discounts as part of your marketing efforts.

Conclusion with additional recommendations

Independent production, purchase of ready-made prefabricated mechanical racks, custom-made - each of the options has its own advantages and disadvantages. Explore not only the potential, but also your own abilities. Sometimes the combined method is optimal, when the project is divided into several parts:

- purchase of factory fasteners;

- ordering complex parts in a specialized workshop;

- independent creation of relatively simple elements;

- assembly on their own, with the help of shareware relatives and friends.

This article simplifies many tasks, but does not provide answers to all practical questions. In order not to waste time in vain on the endless expanses of the Internet - use the comments.Communicate with professionals and amateurs, exchange opinions on the merits of specific engineering solutions.

Video: racking assembly