How to make an epoxy table with your own hands: a master class and creative design options

If you want an original one that does not look like the standard options interior, pay attention to such an unusual piece of furniture as an epoxy table. Such products are always a masterpiece that will attract the attention of your guests. The homemaster.techinfolux.com/en/ editorial team has prepared for you an overview of the most interesting design techniques and detailed instructions on how to make it yourself. countertops.

The content of the article

- 1 Advantages and disadvantages of epoxy countertops

- 2 Epoxy resin table: types and design features

- 3 How to fill the countertop with epoxy resin with your own hands and make a table

- 4 Rules for the care of epoxy tables

- 5 Where can you buy a table made of wood and epoxy resin

- 6 Prices for tables made of wood and epoxy resin: from handiwork to factory models

Advantages and disadvantages of epoxy countertops

Epoxy resin is a chemically complex multicomponent product that has recently been actively used for decorative purposes. The advantages of this material attracted the attention of furniture manufacturers:

- high strength and resistance to deformation and ultraviolet light, no chips and cracks during operation;

- relatively low price for the source material;

- the surface is resistant to the destructive effects of moisture;

- ease of care;

- the possibility of the most diverse processing and filling;

- visual expansion of space due to a glossy finish.

Epoxy tables have their drawbacks:

- high price for finished products. Most of the works are of the author's origin, so the price is determined by the master;

- special requirements for manufacturing technology. The slightest mistake leads to irreparable defects.

Finished products do not tolerate processing with abrasive powders and detergents and are afraid of hot objects

Epoxy resin table: types and design features

Countertops are most often made using epoxy resin. The most popular design options for similar products.

Let's look at the features of the listed varieties of epoxy countertops.

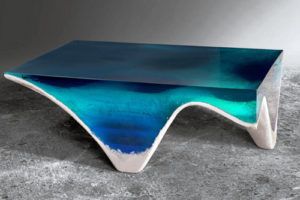

Transparent structures without support surface

For the manufacture of such structures, a casting mold is used. It can have the most bizarre geometry - the more complex, the more interesting. Such countertops are most often used to create coffee or coffee tables... Craftsmen use built-in neon lighting, add inclusions of natural materials to the fill. The addition of water to the filling looks especially impressive - real "space" objects are obtained. Given the lack of a base, you need to take care of the tables made of liquid glass and not subject them to excessive stress.

Interesting ideas for wood and epoxy countertops

Epoxy does not have to be colorless at all - for furniture decoration it is tinted or even matte. Moreover, all inclusions in such a product will be perfectly visible even through a thick layer of chemical glass. An interesting idea is the use of luminescent dyes. The surface of the base, for example, a tree branch, is treated with a substance that can glow in the dark. After pouring, a very original product is obtained.

A favorite design technique is to frame wooden countertops with epoxy. Even boards from old boxes can be used as a basis.

The original design option is obtained if used as a basis Chipboard coated with marble effect. Look no less impressive paintings and still lifes, which are used as a basis for pouring countertops. In short, the design options are endless. Epoxy resin allows creativity and imagination - this is its main advantage. Here are just a few photo examples of epoxy and wood tables.

Related article:

Transparent epoxy potting resin: what can be made of it (jewelry, tables, epoxy floors), composition, how to use epoxy, safety measures when working with the material.

Wooden tables with epoxy resin coating and different filling

By adding various decorative elements under the fill, interior designers achieve stunning effects.

You can achieve the same effect using drawings and ornaments made from natural materials as a basis: shells, dried flowers, colored pebbles, cones

You can use a collection of coins or grandma's buttons, a set of tools, or just a scattering of bolts and nuts. A dilapidated tree looks especially colorful in such a fill: a rotten stump covered with moss, boards scorched by the sun or a piece of log bleached by sea water. All these things will be frozen in resin forever, like prehistoric midges in amber.

Important! Epoxy-coated countertops are quite heavy, so the legs should be chosen especially carefully - they must withstand a lot of stress.

What slab and epoxy tables look like

Slab is a solid solid slab.It can be made of stone or wood. In our case, the stone slab is too heavy a base for the table. But wooden is an excellent base for a countertop. How to identify a slab:

- this is a longitudinal saw cut with raw edges;

- wood thickness - from 5 to 15 cm;

- solid wood is solid, without gluing or other joints.

Such massive elements are preserved in their pristine beauty with all the knots and uneven contours. Now such products are in trend, and many designers use them in interior compositions. Fortunately, now it is not so difficult to buy an epoxy resin countertop or order it individually for a good craftsman.

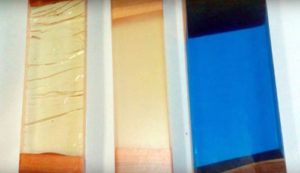

River shaped epoxy table

One of the most popular forms is a table top with a river-shaped epoxy insert. Uneven edges on two wooden parts give a special zest to this type of product. Previously, such tables were made with colored glass, but now epoxy has completely replaced this technology. These tables can be round, rectangular, oval or square - the fill allows you to use any shape and size. In the depths of the "river", the craftsmen place sand, stones and shells, and the filling itself is painted in blue tones. It turns out very picturesque, check out these examples.

Related article:

Epoxy resin for creativity: what it is, its scope and main properties; how to choose and use the material in the manufacture of various products - in our publication.

How to fill the countertop with epoxy resin with your own hands and make a table

Making tables out of wood and epoxy resin is not an easy job, requiring the utmost care and some knowledge of the properties of this material. Before we start considering how to make an epoxy table, we will consider all the features of the future casting.

How to choose and prepare epoxy for pouring countertops

Epoxy resin consists of two reactive components: resin and hardener. While they are in separate containers, they remain elastic. After combining the components, the composition solidifies.

It is more profitable to buy resin in large packages from wholesalers. Now it is not difficult to find such outlets: epoxy is used not only for pouring pieces of furniture, but also for decorating colorful floors. What brands of resin are suitable for the job:

- Art-Eco... The material of this manufacturer is suitable for pouring thin layers. You can buy branded colors to add different shades.

.

- QTP-1130 - the composition is suitable for the thinnest fill up to 3 mm. It is famous for its transparency and self-aligns.

- Crystal glass - transparent viscous composition, ideal for filling herbariums and various fine fillers.

- PEO-610KE - a domestic product, does not grow cloudy or yellow, is not afraid of ultraviolet radiation.

- MG-EPOX-STRONG - the most recommended brand of resin, according to reviews from DIY forums. Excellent combination of price and quality.

Each manufacturer places instructions on how to prepare the composition on the packaging. Usually one part hardener is added to two parts of resin. There are exceptions, so you need to carefully read the instructions and test the mixture on a small object before pouring an oversized product. We offer you to watch the video below how to make a do-it-yourself epoxy fill for the table:

Reviews on the use of epoxy resin for wood tables and other types of products

Concluding the topic of choosing a material for pouring, here are a few reviews from the forums on the use of epoxy.

Feedback on the use of epoxy resin:

Another tip about using epoxy:

Another tip about using epoxy:

Workshop on table filling

Making such a product begins with finding a suitable base material. It can be a simple board with an interesting texture, branches, cuts, pallet boards or fiberboard sheet.

Important points in working with epoxy

In order for the tabletop to turn out the way you intended, you need to follow certain recommendations during work:

- epoxy hardens faster in warmth;

- do not heat the fill from above, it can deform;

- during curing, limit access to sunlight so that the resin does not turn yellow;

- keep in mind that the composition is very toxic, take protective measures;

- when mixing the fill, do not make sweeping and sharp movements so that bubbles do not appear;

- do not leave the flooded countertop in the cold - it will exfoliate;

- so that the resin does not release toxins, cover the finished layer with a protective varnish.

Read more about how to make an epoxy countertop with your own hands in the video below:

Rules for the care of epoxy tables

Wipe such countertops with a soft cloth only. Do not allow nail polish remover, alcohol or hairspray to come into contact with the surface.

Where can you buy a table made of wood and epoxy resin

Such products, as a rule, are works of authorship. Therefore, you can find such tables on the websites of handicraftsmen.

There are several online stores on the network offering batch production products. Better to choose those that are located in your city. Long-term transportation of such items is usually bad for their condition.

Prices for tables made of wood and epoxy resin: from handiwork to factory models

Tables and tables with epoxy filling on one of the most famous sites of handicraftsmen cost from 20,000 rubles, as of October 2018. The price depends on the complexity of the work. There are many options with complex inlay and multicomponent design; it will be possible to buy such tables made of epoxy resin for a price of 50,000-150,000 rubles. As for factory models, for example, the price of Estwood tables starts at 36,000 rubles. and reaches 140,000 rubles, depending on the size and purpose.

If you have experience in working with this material and tips for making such furniture, write in the comments!