Screw piles for the foundation: price with installation, types, production and installation

Often used in the construction of private houses and cottages, strip foundations can not be poured on all soils. Where groundwater runs close to the surface, in areas with flooding, moving and floating soils, reinforcement of the foundation structure is required everywhere. For this, piles are used. These are supports that are laid at a certain depth and tied with a strip foundation. The latter lies on piles, which take all the load from the structure on themselves. There are several types of piles, which differ from each other both in the material of manufacture and in the technology of laying (installation). In today's review, we will look at screw piles for the foundation. The price with installation, dimensional characteristics, how piles of this type are installed - more on all this later.

The content of the article

- 1 Piles for a foundation structure - what is it

- 2 Where are pile foundations used

- 3 What is the screw design

- 4 Calculation and design of screw foundations

- 5 Making screw piles with your own hands: video and photographic materials

- 6 Foundation cost on screw piles

- 7 Rules for the construction of a screw-type pile foundation

- 8 Advantages and disadvantages of the pile-screw foundation

Piles for a foundation structure - what is it

The foundation itself is the support for the house. But he must stand on a solid ground support, otherwise, under the action of loads from the building, it will begin to disperse in different directions, which will lead to the destruction of the building. Weak soils cannot create support for the foundation, therefore, piles are installed under the foundation structure, which, with their lower ends, abut against a strong soil layer located deep underground.

There are several technologies for installing a pile structure, where three main types can be distinguished:

- Driving technology. This is when a reinforced concrete pile is simply driven into the ground using a special installation.

- Bored technology. This is when a well is made in the ground, a pipe is inserted into it, used as a formwork, and concrete mortar with reinforcement is poured into it. After the concrete dries, the pipe is pulled out or left for reinforcement.

- Screw technology. For this, metal piles from a steel pipe are used, in the design of which there is a drill. They are simply screwed into the ground to the required depth.

Where are pile foundations used

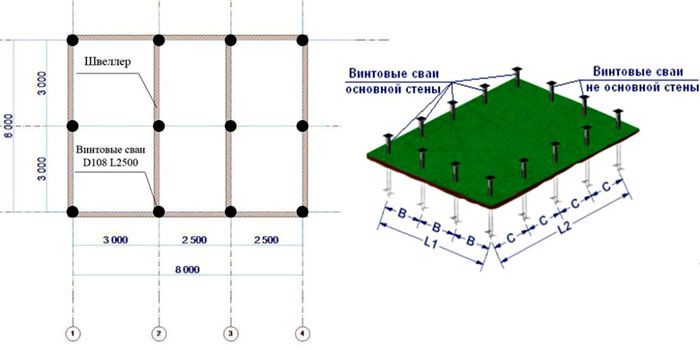

Pile foundations are used in residential, industrial and private construction. As mentioned above, their main purpose is to strengthen the soil on which the building is being erected. In this case, the supports are exposed under the walls of the structure (external and internal) with the obligatory installation of elements at the corners of the building and at the joints of wall structures.

In private housing construction, pile foundations began to be used when the construction boom reigned in the vastness of the country. There were not enough good plots for everyone, and people wanted to have at least a small house away from the bustle of the city. Therefore, the authorities began to allocate land for construction on practically unusable sites. In any case, it was impossible to build a house on it using traditional technologies. This is where they remembered the piles, which were previously used only in civil and industrial construction in the coastal regions and in the North.

As it turned out, the piles easily coped with various inconveniences during the construction of a house and loads, therefore they quickly became popular. In any case, they solved the problem. But hammering and bored technologies are very complex, time consuming and costly. They cannot be carried out without special equipment. Therefore, the technology of mounting the foundation on screw piles has gained great popularity today, which can be done manually without additional costs.

What is the screw design

The photo below shows one pile, which consists of a steel pipe with a screw tip. This is the standard construction used in soft soils. The screw is made of steel sheet by stamping, and its attachment to the pipe is electric welding.

But there are several types of screw-type piles, which differ from each other in the design of the tip.

Tip types and number of screws

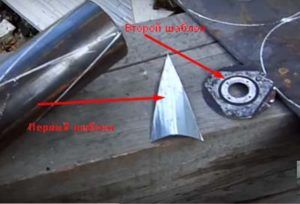

According to the manufacturing technology of the tips, they are divided into welded and cast. The first ones were described above, we repeat - this is a steel sheet, which is given the shape of a screw using the stamping technology, after which it is simply welded to the pipe by electric welding. The latter are cast steel blanks, which are then dimensioned and shaped after finishing.

All tips used in the construction of screw piles are marked:

- welded type - SHS;

- cast - VSL;

- conical - SVK;

- supplemented with a lance - SVP;

- anchor - WOW.

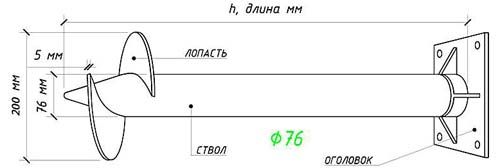

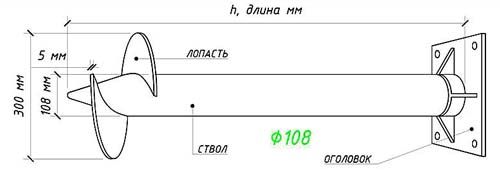

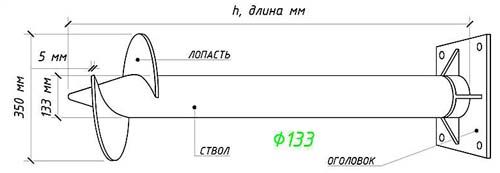

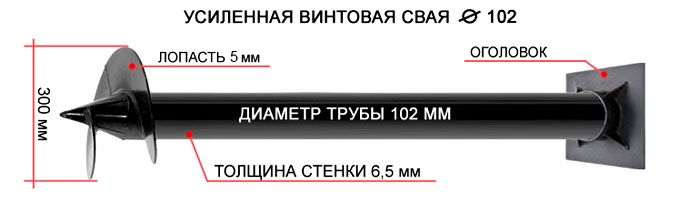

Features of screw piles under the foundation: sizes and series

Let's start with the dimensions, because they determine the bearing capacity of the structure. Screw pile manufacturers offer products based on pipes of different diameters. This parameter varies within 57−325 mm. In private housing construction, products with a diameter of no more than 133 mm are used. The table below shows piles with different sizes and definitions of what loads they can withstand.

We add that manufacturers produce screw piles of different series that solve various problems:

- "Z" series - standard construction used for light structures;

- "T" - holes are made in the head structure for fastening a metal or wooden grillage;

- "U" - for this series, the head has a U-shape;

- "F" - a round flange is installed on top of the pipe;

- "R" - square flange.

Pipe wall thickness

Since the standard size of pipes is not only their diameter, but also the wall thickness, then, based on this parameter, it is possible to determine the bearing capacity of the product. But when drawing up a project for the foundation of a house on piles, other characteristics must be taken into account. For example, the activity of groundwater. It can contain a high concentration of salts that corrode the metal quickly. This means that in such a situation it will be necessary to use pipes with a thicker wall in order to extend their service life.

So, the pipes used in the manufacture of screw piles are divided into three groups depending on the wall thickness:

- Thin-walled. Their wall thickness does not exceed 3.5 mm.

- With an average wall thickness. This parameter ranges from 3.5 to 6 mm.

- Thick-walled - over 6 mm.

Now for the thickness of the metal used to make the blades. There are two groups here:

- Up to 5 mm. These screws are mounted on piles that can be used to erect lightweight structures.

- Over 6 mm. Piles with such screws can be installed under houses built from heavy building materials.

And there are literally three positions concerning the steel grade for foundation racks:

- Pipes and blades made of St3 steel can be used if the groundwater has a weak chemical activity.

- St20 for moderately aggressive waters.

- And steel 09G2S or 30XMA for areas where aggressive soils are present.

Anti-corrosion coating

Since the screw piles are located in moist soil, plus the underground water will constantly affect the metal, every effort must be made to carry out anti-corrosion protection. There are several modern technologies that are divided into three groups:

- zinc plating;

- coating with polymer compounds;

- covering with protective enamels and primers.

All manufacturers today carry out protective measures in the factory using one of these technologies. But, as practice has shown, not all of them provide the required standards that affect the service life of supports in the ground. For example, cold zinc plating is better than hot zinc plating. Polyurethane and epoxy primers are superior to other polymer primers. Today, it is proposed to paint metal products with special compounds that are applied over rust. At the same time, rusty surfaces are not treated with anything, but the protection becomes very effective, even better than galvanizing.

If the screw piles for the foundation are made by hand, by the way, the video will be shown below, then you will have to choose an anti-corrosion material and apply to the finished product yourself. It should be added that the market is filled with products of dubious quality. More and more often there are “bare” piles, so to speak, untreated with anti-corrosion protection. It is not recommended to purchase them under a bookmark at home. They can only be used for protective structures and buildings of an economic type. Of course, you will have to paint them before installing.

Calculation and design of screw foundations

The simplicity of building a foundation of this type does not mean that it should be treated from the position of simple calculation. In the above table, the bearing capacity was indicated. It is he who is taken as the basis of the calculations. But, besides this, there is another parameter on which the quality of the final result depends. This is the arrangement of the supports relative to each other. Here we mean the distance between the posts, and, accordingly, in this way, and number of piles.

Load bearing capacity

This parameter does not have an exact value, judging by the tabular indicators. The spread is quite large, for example, from 5000 to 9000 kg, therefore it is very important to accurately calculate the weight that one pile can withstand in the project of a particular house. And here a lot will depend on the bearing capacity of the soil itself. This is what is taken into account when calculating the bearing capacity of the foundation. Therefore, it is very important, before drawing up a project and carrying out calculations, to carry out geological surveys.

Calculator for calculating the bearing capacity of screw piles

Foundation load

The second important parameter that must be calculated accurately is the load from the building on the foundation itself. The calculation is quite complicated, because it is necessary to take into account the weight of all materials spent on construction. And since a large number of them are used by type, it is not always possible to take everything into account. Therefore, there are simplified formulas. But it is better to use an online calculator, the parameters of the house and the materials from which it was built are entered into it.

Calculator for calculating the load on a pile foundation

How to determine the number of piles

So, if the calculations of the bearing capacity of one pile, which will be used in the construction of the house, and the load of the entire house on the foundation have been completed, then the number of required piles can also be determined. To do this, the second parameter must be divided by the first. Although this is just a general formula, because there are certain standards for the placement of supports.

Making screw piles with your own hands: video and photographic materials

In principle, there is no particular difficulty in the manufacture of screw piles. Because this is a pipe on which you need to make a spear-shaped tip and install the blades. All fixings are welded.

Do not forget to treat the finished product with an anti-corrosion compound. For better screwing in of the piles, the edges of the blades are sharpened with a grinder so that they become sharp.

Foundation cost on screw piles

It must be distinguished that the prices for screw piles for the foundation with installation differ from the finished products, which are sold as a separate product. With a seemingly large difference in price, the service of building a foundation on turnkey screw piles is much better. Because the piles will be brought to the site by the manufacturer. She will also calculate their number and lay out the structure on the ground.

And the main thing is a high-quality installation of supports. Despite the seeming simplicity, there is a lot to consider here, special attention should be paid to the verticality of screwing in the racks. And if it is done by professionals, then we can talk about the high quality of the final result.

So, what are the prices offered by manufacturers today? Let's designate the average value of the cost of a screw pile with an installation with a diameter of 133 mm and a wall thickness of 4 mm. Prices depend on the screw-in depth, respectively, on the pile length.

| Pile length, m | 2 | 2,5 | 3,0 | 3,5 | 4,0 | 4,5 | 5,0 | 6,0 |

|---|---|---|---|---|---|---|---|---|

| Price with installation, rub. | 3800 | 4100 | 4500 | 4800 | 5200 | 5700 | 6200 | 7200 |

The cost values differ by region, so you need to clarify the prices.

At what price can you buy the screw piles for the foundation?

Here, as in the case of turnkey installation, a lot will depend on the length of the pile and its diameter. But the price component also includes the type of head, the type of the tip and the method of protective measures taken. Let's disassemble a pile with a pipe diameter of 73 mm and a wall thickness of 5.5 mm, a blade diameter of 250 mm, and a thickness of 5 mm. Propeller design - two blades (360 ° rotation), protection - anti-corrosion enamel.

| Pile length, m | 2 | 2,5 | 3,0 | 3,5 | 4,0 | 4,5 | 5,0 | 6,0 |

|---|---|---|---|---|---|---|---|---|

| price, rub. | 1500 | 1700 | 1800 | 1900 | 2000 | 2200 | 2400 | 2600 |

Prices, again, differ by region and manufacturer, so before deciding where to buy screw piles for the foundation, it is recommended to collect some information about the company that manufactures the products. Better to give preference to the one with more positive reviews. Even if the piles will cost a little more, this is a guarantee of their long-term operation.

Rules for the construction of a screw-type pile foundation

Regardless of what area the building will occupy, for example, 20 × 20 or 4 × 3 m, the construction of the foundation on screw piles is carried out using the same technology. The price of the project changes by increasing or decreasing the number of supports.

Related article:

DIY foundation on screw piles. Any more or less competent builder is quite capable of making such a structure. Its advantages and disadvantages, installation and finishing features are all about this in our material.

Advantages and disadvantages of the pile-screw foundation

At the end of the article, I would like to outline the pros and cons of a house built on screw piles. Let's start with the benefits:

- Such a foundation can be built on any type of soil.

- Groundwater is not a hindrance to construction.

- The level of freezing is also not a fundamental factor.

- This design is the best option for building a house on difficult terrain.

- Installation of piles is possible in all weather conditions.

- Frost heaving does not in any way affect screw piles during their operation.

- Simplicity of the installation process.

- Fast terms of work. A mechanized team can screw in several dozen piles per shift.

- Minimum costs for the production of work due to the absence of such processes as digging a foundation pit or trenches, installing formwork, pouring concretealigning the construction site.

- The pile-screw foundation can be loaded immediately after the supports are screwed into the ground.

- Designing the house itself can be carried out during the assembly of the foundation.

- Long-term operation of the structure.

- If you correctly approach the insulation of the foundation, then we can talk about the possibility of building a basement.

- The cost of erecting a pile-screw foundation is 30-50% less when compared with a concrete structure.

Now about the disadvantages of the foundation erected on screw piles:

- The main difficulty lies in the fact that screw piles are very difficult to screw into rocky soil.

- If the calculations are incorrect, then we can talk about the guaranteed deformation of the entire structure.

- There is always a high probability of metal corrosion.

- They cause difficulties in screwing in the racks in places where they are close to adjacent walls.

So, in this article, we have covered everything related to screw piles and the foundation of them. If you have any questions, we are ready to answer them. Write in the comments what we did not cover in this review or what else interests you, besides the information in the article.