Epoxy grout for tiles: pros and cons of use, instructions for use

When performing finishing work, it sometimes becomes necessary that the material used has not only decorative properties, but can also perform a protective function, while maintaining its physical properties for a long time. It is to such materials that epoxy grout for tiles belongs, its properties and scope, as well as the composition and advantages of use - this is the topic of this article for the readers of the online magazine homemaster.techinfolux.com/en/.

The content of the article

- 1 Scope of application

- 2 Composition and main characteristics

- 3 Pros and cons of using

- 4 Features of epoxy grout for tiles "Litokol" and "Ceresit"

- 5 Comparison of the properties of cement and epoxy grout

- 6 Instructions for preparation and use

- 7 At what price and where can you buy epoxy grout for tiles - an overview of current offers

- 8 Consumer feedback on epoxy grout for tiles

- 9 Video: how to work with epoxy grout. Workshop on grouting tiles!

Scope of application

This type of grout is used when performing finishing work both indoors and outdoors, due to the physical properties of such compounds. Resistance to water and chemically active substances significantly expands the scope of use of grouts based on epoxy resins.

This material is used for:

- grouting of tile joints in damp and damp rooms located inside buildings and structures (bathrooms, bathrooms, corridors and others);

- finishing of swimming pools and other water objects (fountains, water slides, etc.), as well as when grouting tiles and mosaics mounted in shower cabins, saunas and other bath and laundry facilities;

- finishing of building structures exposed to significant external influences during operation (steps of stairs, floors, walls);

- grouting various joints up to 15 mm wide - as an alternative to other types of similar materials, including in rooms where systems are installed "Warm floor".

The use of epoxy compounds when finishing the pool bowl will secure its use in various life situations

Composition and main characteristics

Epoxy grout is a two-component material consisting of epoxy resin and a catalyst, usually made from organic matter. The catalyst is a hardener by the type of action on the epoxy resin. In addition, to give the finished composition an attractive appearance, secondary fillers are added to it: dyes, glitters, mother-of-pearl and even gold-containing dust.

The main characteristics of this material are:

- resistance to moisture, detergents and other substances, based on chemically active elements;

- strength;

- long service life without loss of external indicators (color change, shrinkage) and physical properties.

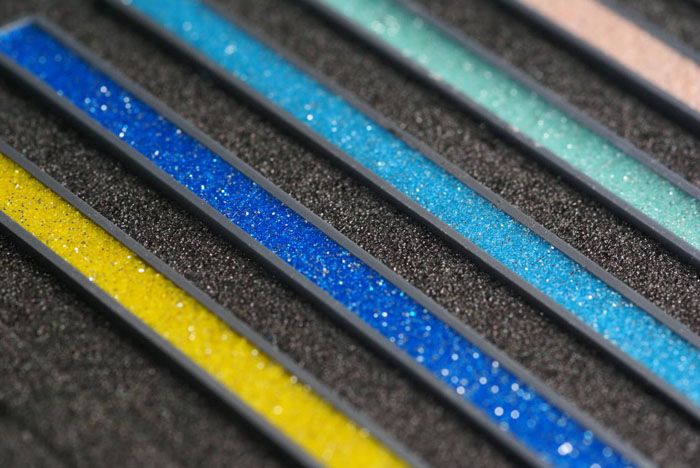

A variety of secondary fillers allows you to create a composition of an individual color required for the design of the space

Pros and cons of using

Epoxy-based grout, as, indeed, all building materials, has its inherent advantages, which can be formulated as follows:

- resistance to ultraviolet radiation;

- not susceptible to shrinkage and cracking after solidification;

- long service life;

- high strength;

- resistance to temperature conditions of use and temperature extremes;

- not susceptibility to chemical detergents;

- hypoallergenic.

The disadvantages include:

- the ability to quickly solidify reduces the time of use after preparation;

- the need for certain experience in working with the composition and the method of its preparation;

- work must be performed using special tools and personal protective equipment;

- the complexity of dismantling if necessary;

- high cost in comparison with analogs made on other bases.

Working with special tools and personal protective equipment will prevent negative effects on the worker's skin

Features of epoxy grout for tiles "Litokol" and "Ceresit"

In the group of grouts used for finishing works made on the basis of epoxy resins, the most popular brands among professionals and ordinary users are "Litokol" and "Ceresit".

Epoxy grout "Litokol"

The company "Litokol" (Italy) produces several types of epoxy grout:

- Starlike 350 Crystal - a colorless mixture with a "chameleon" effect, used for the treatment of glass surfaces and mosaics. The maximum thickness of the layer to be laid is 2 mm;

- Starlike Defender - acid-resistant two-component mixture, has an antibacterial and antifungal effect. Used when grouting tile joints up to 15 mm wide, available in seven color options;

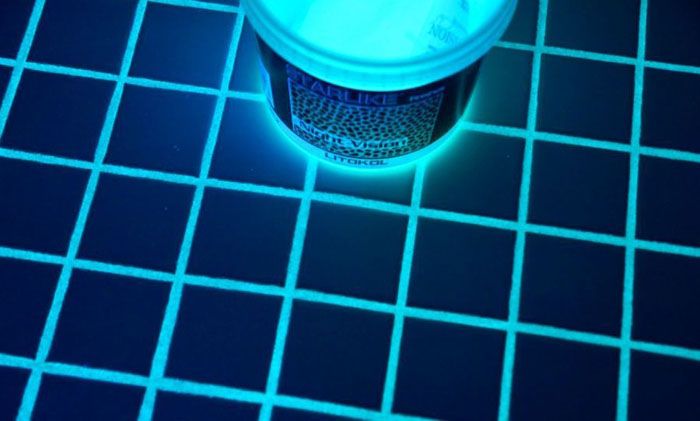

- "Litochrome Starlike" - can be used for external and internal work with a joint thickness of up to 15 mm. This brand is available in 103 color options and has a whole range of decorative effects - from luminescent to metallic, which are created using special dye additives;

- "Epoxystuk X90" −this grout is intended for use in aggressive environments and is acid resistant. It can be used for external and internal works.

Ceresit epoxy grout

The company "Ceresit" (Russia-Germany) produces a wide range of building materials: from tile cladding and waterproofing to plaster and finishing mixtures.

In the category of epoxy-based tile grout, there is a brand Ceresit CE 79 UltraPox... This water-resistant two-component mixture is resistant to chemical attack, abrasion and can be used for exterior as well as interior work. Grout color is gray.

Comparison of the properties of cement and epoxy grout

Grades of grout made on a cement and epoxy base have their own advantages and disadvantages due to their physical properties, which determine the possibility of using one or another type of this finishing material. Cement-based formulations are available in two versions: dry or ready-made. To use dry brands, you must mix them with water or latex, and ready-made ones can be used immediately after opening the container in which they are sold.

This species has the ability to long-term storage, especially for dry formulations. In addition, their advantages are considered to be ease of use and high quality of the result obtained. The disadvantages of cement-based brands include: destruction under the influence of external mechanical influences, the ability to transmit moisture and pollution.

Epoxy based grouts do not have the above disadvantages, however, they are difficult to use and are subject to rapid hardening after mixing the components of the mixture.

Key benefits yesof a different type of material, in comparison with cement-containing ones: the possibility of using in aggressive environments, resistance to moisture penetration and long service life.

Before starting work on grouting tile joints, it is necessary to prepare a tool and personal protective equipment

Instructions for preparation and use

Working with epoxy grout is a rather complex process, which requires certain skills and care during its implementation. All work can be divided into several stages: preparatory, work execution and final.

Preparatory stage

At this stage, the material is purchased, the tools necessary for the work are prepared:

- electric drill or screwdriver with a mixer, used for mixing the components of the prepared composition;

- a bucket or other container in which this composition will be prepared;

- rubber (metal) putty knifeused for applying grout;

- cellulose sponge designed for grouting and formation of tile joints;

- grater - used to remove excess material after application;

- personal protective equipment - gloves.

When preparing the composition, it is necessary to observe the proportions recommended by the manufacturer, as well as to use dyes compatible with the brand of the material used.

Execution of works

Initially, it is necessary to mix the existing components of the material used - epoxy resin and hardener. Before that, you should select the color of the grout, if this was not done at the stage of its purchase (brands "Litochrome Starlike" or "Starlike Defender"), for which a dye is selected, its amount is determined. The amount of dye must be determined empirically by mixing a small volume of the composition. In addition, if necessary, to give plasticity to the prepared material, you can add a plasticizer corresponding to the brand of grout. When the issues are resolved with all the components, you can start preparing the mixture.

When mixing, the finished composition must be strictly homogeneous, otherwise the quality of the work performed will be low

This is done as follows:

Once the grout has been prepared, you can start filling the joints. These works are performed in the following sequence:

Important! In the presence of deep and wide inter-tile joints, the operation of laying the grout and subsequent grinding must be performed in several approaches.

The remaining parts of the finished mixture are removed after they have dried on the second day of work.

The final stage

The next day, after the main stage of the work has been completed, you need to perform a number of more operations:

After complete drying, the surface is checked again for the presence of epoxy deposits and residues of the composition, if any, the work is repeated.

At what price and where can you buy epoxy grout for tiles - an overview of current offers

The price of epoxy grout for tiles in different trade organizations may differ, which is due to the sales volumes of similar companies, the level of specialization, as well as the presence of dealer contracts with manufacturers. The following table shows the cost per grades of epoxy grout used when laying tiles and other finishing materials, as of the beginning of the second quarter of 2018, when sold through large retail chains of building materials.

The luminescent properties of epoxy grout create individuality and uniqueness of the room in which the decoration is made using them

Consumer feedback on epoxy grout for tiles

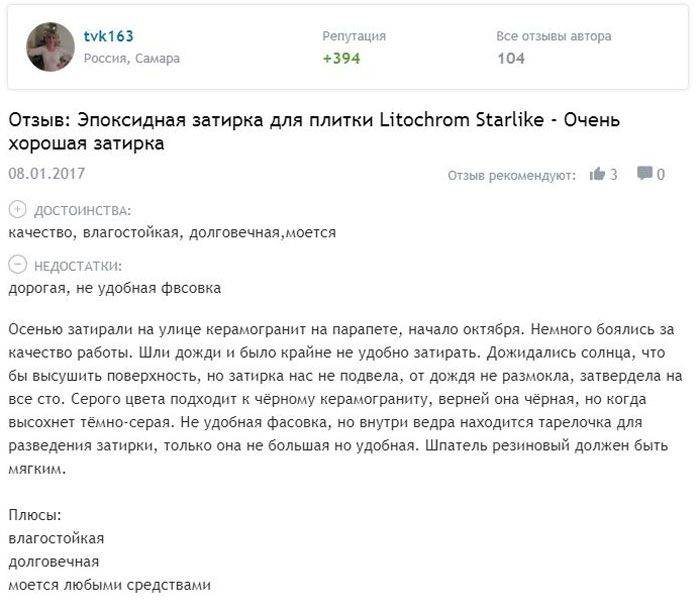

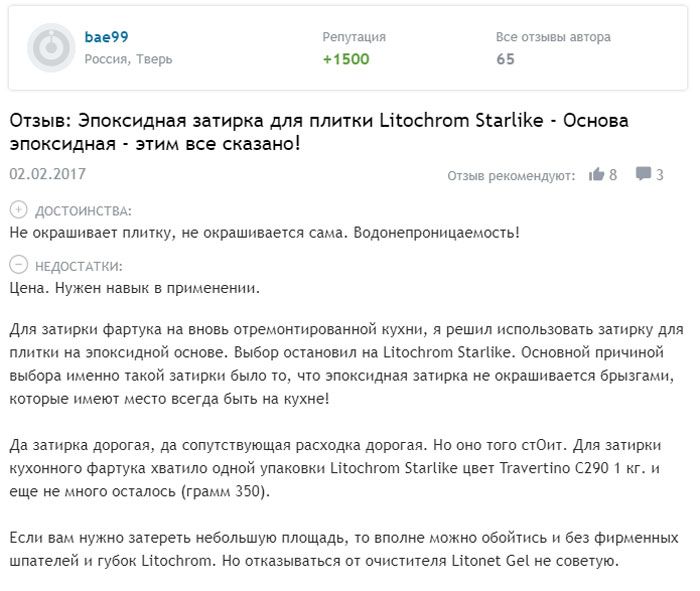

On the Internet, you can find reviews of experienced users about almost everything that is produced and sold on our planet, and, of course, you can find there the opinions of consumers who have already used epoxy grout when installing tiles and other finishing materials, here are some of them.

Feedback on grouting brand "Litochrom Starlike":

Another tip about Litochrom Starlike grout:

Another tip about Litochrom Starlike grout: