How to choose a tile adhesive: characteristics, scope, manufacturers

After the start of repairs in an apartment or house, sooner or later the question will arise - which adhesive for the tile to choose? Of course, having come to the store, you can ask the seller or consult with the master. However, the former wants to sell the glue at a higher price, while the latter will choose a composition that is easier to work with. In both cases, the customer will be the loser. Choosing on your own, focusing only on the inscriptions on the bags, is also not an option. There are many nuances on which the quality of work and the reliability of fixing the tiles to the base strongly depend. This article provides information on the main types of adhesives in accordance with the EN 12004 standard, their areas of application, as well as the main brands from leading manufacturers.

The content of the article

Main characteristics and their influence on the choice of adhesive composition

- Substrate adhesion. It is the main parameter of adhesive mixtures. It is measured in megapascals (MPa). The value of this indicator means the number of kilograms that need to be applied in order to tear the tile from the base. In practice, adhesive mixtures with standard adhesion can be used for tiling horizontal surfaces (non-stressed floor) with small and medium-sized tiles. Compositions with enhanced adhesion are used for finishing vertical surfaces, as well as for laying large tiles.

- Frost resistance. The first thing to look for when choosing tile adhesive is whether the work is done indoors or outdoors. The mixture used for laying ceramic tiles or porcelain stoneware on the street must withstand temperature changes over a wide range and have high frost resistance. With the help of various additives, such glue is made more elastic, since the base surface of building structures located on the outside of the building is, as a rule, more uneven and have many defects, cavities and cracks.The price for such an adhesive mixture is higher.

For fixing porcelain stoneware outdoors, an adhesive with a high degree of frost resistance is required

- Moisture resistance. Compositions for interior work also differ according to the place of use: bathroom, hallway, kitchen... At this stage, the main characteristic is moisture resistance. Naturally, it is necessary to choose a more moisture-resistant glue for the bathroom and shower. The parameters of moisture resistance and frost resistance are interrelated, the less the glue absorbs moisture, the higher its frost resistance.

Important! The DIN EN 12004 (12002): 2007 standard was developed and adopted by the German Institute for Standardization Deutsches Institut für Normung and has been operating in European countries since 2007. Translated and registered by STANDARTINFORM FSUE on 07/31/2012. All tile adhesives produced in Russia, without exception, must be marked in accordance with this standard. If not, then such a manufacturer and his products should be treated with extreme caution.

- Elasticity. This parameter is one of the key ones, since elastic compounds are able to withstand and more evenly distribute the loads on the facing surface. That is, they act as a kind of damper, preventing deformations of the base, leading to cracking of the tiles. It is also recommended to purchase tile adhesive with increased elasticity in the following cases:

- if the base is aerated concrete (gas and foam concrete), gypsum blocks and drywall all types of cement-based blocks: cinder blocks, expanded clay concrete, etc .;

- when installing a warm floor, it prevents the tiles from peeling off as a result of temperature deformations from heating and cooling;

- for large-format slabs - provides a longer period for correcting the position of the tiles after laying, which is very important when facing the surface with heavy large slabs of porcelain stoneware;

- when using glazed ceramic tiles - this is not directly indicated in the specifications, but in practice, the use of glue with low elasticity can provoke the appearance of cracks on the glazed surface. Obviously, this is due to the occurrence of internal stresses from the influence of deformation of the base, which is directly transferred to the cladding through inelastic glue.

Laying of ceramic tiles on a warm floor is carried out with an adhesive mixture with high elasticity

- Spreadability. An important parameter for laying tiles on horizontal surfaces. Thanks to this characteristic, the adhesive mixture fills all cracks and voids, providing a large adhesion area. For vertical surfaces, on the contrary, high spreadability is a negative factor.

- Thixotropy. We will not go into the physical characteristics of this phenomenon. Applied to adhesive mixtures, this parameter means that the tiles will not slide off vertical surfaces when facing. Naturally, it is recommended to purchase glue with high thixotropy for wall decoration, and low thixotropy for floor decoration.

Laying ceramic tiles on a wall without a support strip is only possible with compounds with high thixotropy

- Open time of use (confidently open time). Typically, tile adhesive is applied to the substrate surface. Time from the moment the glue is applied to the floor or the wall before the tiles are laidis called open. This parameter must be indicated on the packaging. The higher it is, the more operational time the stacker master has. This significantly affects the speed of veneering, as it reduces the number of operations.

The application of tile adhesive over a large surface area is allowed only with a significant period of open time of use.

- Correction time. The period during which the master can correct the position of the tiles after laying.

The correction time of the laid tiles is an important indicator, especially if you are going to do the installation yourself

Classification and brands of adhesive mixtures

Any manufacturer of high-quality tile adhesive must submit its products for certification. According to its results, the corresponding marking is applied to the packaging with the dry mix. The most complete and generally accepted standard by which the classification of tile adhesive is carried out is the European - EN 12004.

C1 / C2

C1. Cement based adhesive with adhesion to the substrate from 0.5 to 1 MPa. Open time of use does not exceed 20 minutes. Correction time - 15 minutes.

Example: Ceresit CM 11, Mapei Mapekley Extra, Quick-Mix FK100 / 300, Litokol X11.

C2. Cement based adhesive with enhanced adhesion, more than 1 MPa. Used in the following cases:

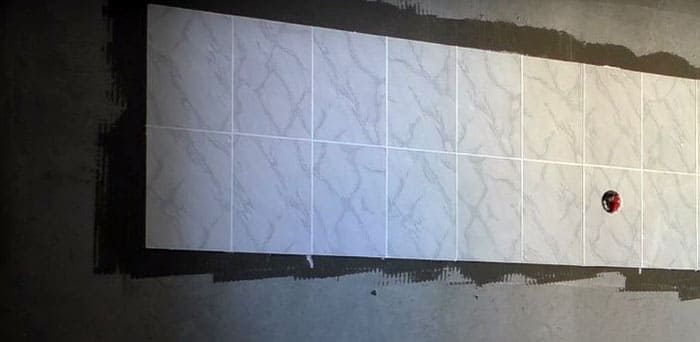

- for fixing large format slabs and weighing more than 40 kg / m²;

- for laying large-format cladding on vertical surfaces;

- for cladding horizontal surfaces that will be subject to significant loads.

Example: Lito Floor K66, Ceresit CM 14, Quick-Mix RKS.

R

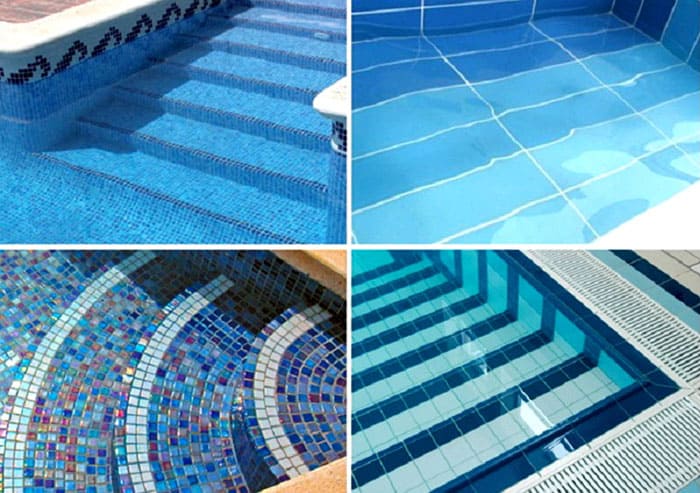

Reactive adhesives based on polymer resins (epoxy, polyurethane), which show their properties only after reacting with a special catalyst. They have improved adhesion and elasticity. Sellers and craftsmen most often call them polyurethane adhesives, regardless of their composition. They must be combined with epoxy-polyurethane grouts. As a rule, they are used for facing swimming pools or steam rooms in saunas. These formulations are applicable to virtually any type of surface, including glass, metal and wood. In industry, they are often used in chemical laboratories, workshops for the processing of meat and dairy products, in pharmacological industries. They are distinguished by their particularly high resistance to acid and alkaline influences. In everyday life, this is manifested in the ability to clean the lined surface with any aggressive detergents.

Example: Mapei Keralastic T, Litoelastic.

F

An additional parameter that characterizes C1 and C2 cement adhesives as Fast. This means that this adhesive mixture will harden much faster, which has a significant impact on reducing the time required to complete the work. For most popular brands, grouting of ceramic tiles laid on such glue can be carried out within 4-5 hours after laying. And after another 3-5 hours, technical movement on the surface is allowed.

It is recommended to use the fast adhesive when laying tiles with a high degree of moisture absorption. For example, some types of porous natural stone or clinker tiles. Conventional adhesive mixtures are not suitable for such materials, since moisture from the solution is quickly absorbed into the finishing material and the adhesion to the base surface is poor. The open time for using such glue is also significantly reduced to 10-20 minutes.

Important! Some caution should be used to speed up repairs using fast adhesives. First of all, their cost is much higher than standard ones. In addition, shortening cement working time and open time can result in poor job performance.

Example: Litokol K17 Fast, Mapei Adesilex P4, Mapei Granirapid, Litokol LitoStone K98 / K99, Mapei Elastorapid.

T

The thixotropy of the adhesive characterizes its ability to prevent tiles from sliding off a vertical surface under the influence of gravity. The physical characteristics of such a solution change abruptly. When at rest, the thixotropic is very malleable. The tile is laid on it and positioned with smooth movements.After the impact on the solution stops, it instantly thickens and keeps the tile in its original state.

Thixotropic adhesive mixtures are recommended for use when cladding facades with clinker tiles large format, finishing made of artificial and natural stone, having a lot of weight. In this case, the installation of tiles can be performed both from the bottom up, using a stop, and from top to bottom. The level of thixotropy and the quality of work are checked with tiles 150 × 200 mm. The permissible slippage should not exceed 0.5 mm.

Example: Mapei Kerabond T / Adesilex P9 / Adesilex P10 / Keraflex Maxi / Keraflex / Ultralite S1 / Elastorapid, Ceresit CM 16 / CM 115 / CM 117 / CM 17, Quick-Mix FX600, LitoPlus K55; Superflex K77.

E

Increase in open time of use, as a rule, up to 30-40 minutes. without reducing the adhesive properties and adhesion level. The tile adjustment time is automatically increased. Such formulations are very convenient for non-professionals.

Example: Litokol Litoflex K80, Ceresit CM 115 / CM 117 / CM 17, Mapei Adesilex P9 / P10 / Keraflex Maxi / Keraflex / Ultralite S1 / Elastorapid, LitoPlus K55, Superflex K77, Quick-Mix FX900.

As a rule, the open time value is an additional characteristic of special-purpose adhesive mixtures.

S1 / S2

The elasticity index characterizes the deformability of the adhesive (without destroying the integrity of the coating) in the hardened state. This indicator is key for building structures that are exposed to temperature, humidity or vibration loads. Typically it is building facades located close to heavy traffic routes. Also, it is recommended to use glue with increased elasticity when laying large-format tiles on deformable bases (wooden floor), in technologies warm floor of any type and in other cases when the redistribution of deformations between the base and the external facing surface is important. There are two levels of elasticity:

- S1 - withstands an information load of 2.5-5 mm;

- S2 - withstands a deformation load of more than 5 mm.

When cladding structural elements in swimming pools, steam rooms, showers, as well as when laying large tiles, it is recommended to use adhesives marked S2.

Example: Mapei Ultralite S1, Quick-Mix Fx900, Litokol X11 + Latexkol-m, Litokol LitoStone K98-K99 + Latexkol-m.

A high rate of elasticity is characteristic of adhesive mixtures used for facing mosaics and tiles for heated floors

It should be noted that an increase in the elasticity of standard cement-based adhesive mixtures can be achieved by adding some latex primers, completely or partially replacing water. At the same time, the addition of a latex primer to elastic compounds to improve their characteristics is strictly prohibited. Too much latex will significantly reduce the adhesion performance.

Leading manufacturers

Among the manufacturers of adhesive mixtures, special attention should be paid to the following companies:

- Ceresit - production Russia - Ukraine, license and recipe Henkel Germany;

- Knauf - production Russia - Ukraine, license and recipe Knauf Germany;

- BERGAUF - production Russia, license and recipe BERGAUF Germany;

- Litokol - Italy;

- MAPEI - Italy;

- VOLMA - Russia;

- UNIS - Russia.

Special formulations

There are many building structures that have special modes of operation. This is mainly due to high temperature and humidity: stoves, fireplaces, swimming pools, saunas, steam rooms, etc. In addition, many finishing materials require special aesthetic characteristics of adhesive mixtures.

Heat-resistant compounds

Heat-resistant or refractory tile adhesive is made on the basis of Portland cement, quartz sand and fireclay clay. To increase adhesion, elasticity and water resistance, polymer modifiers are added to it. You should be especially careful in the process of using it, since many brands of heat-resistant glue have a special application technology. For example, "Ivsil Termix" contains a high content of silicates, and special aluminate cement is used as an adhesive.A feature of its application is the application of an adhesive mixture to the surface of the base 10-15 minutes before the start of facing work. For most other formulations, such a pause in the open time of use is critical, after which the formulation applied to the surface becomes unusable for further use.

Example: IVSIL TERMIX, heat-resistant Terra, heat-resistant Hercules, Profix RHZUA 895.

Video: tile adhesive - manufacturer comparison

Moisture-repellent mixtures

Water-repellent tile adhesive is used for lining swimming pools, showers, washing rooms, steam rooms, etc. In addition to water resistance, such compositions must have:

- high adhesive properties;

- elasticity;

- resistance to aggressive chemicals. In particular, chlorine and mineral salts dissolved in water;

- hygiene, antiseptic properties and resistance to algae, fungus and other types of biological corrosion;

- resistance to mechanical stress - pressure;

- resistance to temperature changes.

In practice, mixtures for swimming pools are rarely found. As a rule, these are reactive adhesives based on epoxy and polyurethane resins, marked "R". Most often, high moisture resistance is one of the characteristics of highly elastic, universal adhesives. For example, Ceresit CM 17 / CM-117, Siltek T-81.

In most cases, the moisture-repellent tile adhesive used in swimming pools is white, as mosaics are often used as cladding

White tile adhesive

Many types of facing materials made of natural stone (marble) ceramics are available in light colors or even white. Recently, facing made of glass or translucent mosaics has become quite popular. White tile adhesive is used to lay such specific materials. It contains white Portland cement, white sand and various polymer modifiers, due to which the required performance characteristics are achieved. The cost of such glue is quite high, but there is practically no alternative to it.

Example: IVSIL MOSAIK, LITOKOL LITOPLUS K55, UNIS BELFIX 25kg, Bergauf Mosaik, Ceresit CM 115, LITOKOL LITOSTONE.

What affects the consumption of tile glue

Usually, on bags of tile glue, the consumption is indicated based on the thickness of the glue layer of 1 mm. In practice, the thickness of the adhesive on a perfectly flat surface will be within 3 mm. In addition, there are a number of factors affecting the increase in the consumption of the adhesive mixture:

- Tile type. Porous and hygroscopic, it absorbs more moisture and requires a thicker layer of adhesive than dense, glazed tiles.

- The thickness, size and relief of the tile surface. All these factors, and especially their combination, can significantly increase the consumption of the adhesive mixture. This is especially true for the size. If for a tile with dimensions of 10 × 10 cm² the thickness of the glue does not exceed 2 mm, then for 20 × 30 cm it will already be about 3 mm, and for 50 × 50 cm² at least 4.5 mm.

- Preparation of the base. If the difference in the surface of the base does not exceed 3-5 mm, thin-layer laying is allowed using notched trowels. The size of the tooth, and accordingly the consumption of glue, also directly depends on the dimensions of the tile. The larger the tile, the larger the tooth should be.

Floor tiles, imitating natural materials, have a porous structure, the consumption of the adhesive mixture for its installation significantly exceeds the accepted norm

Preparation of the base for laying ceramic tiles significantly reduces the consumption of the adhesive mixture

conclusions

Knowing the properties of the tile adhesive, you can easily select the required grade for tiling work in each case.It should be remembered, however, that universal adhesive mixtures are quite good when laid on a solid, non-deformable base of medium format tiles. Provided that the tiled surface will not be further exposed to too intense external influences.