Siding "under the tree" - the main characteristics, varieties, features of choice

The main trend in modern design is the widespread use of natural materials. One of them is wood. However, the wood's performance is rather mediocre. Especially when compared with synthetic finishing materials. Therefore for facade finishes often used siding "wood" made from other raw materials, more resistant to external factors. This article will describe the main parameters of various types of siding, their advantages and disadvantages, recommended areas of use, as well as installation technology.

The content of the article

Siding "under the tree" - materials

Siding is a finishing material used for cladding the surface of building structures. Usually it has the form of strips 10-30 mm wide and 2-6 m long, the thickness does not exceed 10 mm. The front side can be smooth or have a relief imitating the texture of natural materials. The inner surface, depending on the method and material of manufacture, has stiffening ribs. Also, the design includes various fasteners, locks and perforations to facilitate the installation process.

The modern market of finishing materials offers siding made from the following raw materials:

- polymers (vinyl, acrylic);

- metal (aluminum, galvanized steel);

- fiber cement;

- ceramics;

- wood.

Let's consider each of the types of the listed raw materials in more detail.

Vinyl

The material for making vinyl siding is polyvinyl chloride (PVC)... Depending on the field of application, it is produced in several modifications:

- Wall - product thickness no more than 3 mm. It is used for cladding facades, in insulation systems or for their restoration.

- Basement - considering that on base / plinth trim and foundation more intense mechanical influences appear, the thickness of the siding can be increased up to 5 mm.

Has a wide range of colors. The outer surface can be either smooth or embossed to imitate the texture of wood. It can be operated in a wide range of temperatures: -50 ° C ... + 50 ° C. The material is resistant to all types of biological and chemical corrosion. During operation, it does not crack or deform. When purchasing vinyl siding, pay attention to its fire-fighting properties. Most modern manufacturers add fire retardant additives to raw materials. They change the flammability class of polyvinyl chloride from G4 (highly combustible materials) to G2 (moderately combustible building materials).

Acrylic

Acrylic siding is a relatively new type of polymer finishing material that first appeared on the market in 2016. The raw material is acrylic-styrene compound. It is produced by extrusion followed by embossing on the front side, imitating the texture of wood. Has a higher performance than vinyl. In particular, it is more resistant to extreme temperatures, does not fade under intense exposure to ultraviolet radiation, is more plastic and resistant to mechanical stress. On average, the cost of acrylic siding is 20-25% higher than vinyl siding, but it has improved aesthetic characteristics.

Important! Almost all manufacturers claim that the lifespan of plastic siding types is 50 years. However, as practice shows, plastic trim becomes unusable much faster due to mechanical damage.

Metal siding

The material for the manufacture of metal siding is galvanized steel or aluminum. Manufacturing is carried out by the rolling method. In one pass, the product is shaped, and some manufacturers apply a relief that imitates the texture of wood. The panel thickness does not exceed 0.9 mm (mainly 0.45-0.6 mm).

The facing material turns out to be quite light, which makes it possible to do without additional reinforcement of the supporting frame. The following materials are used as an external polymer coating:

- polyester - the surface is plain, smooth, glossy or matte;

- plastisol - embossing is applied, imitating the texture of wood;

- pural - has high resistance to ultraviolet radiation (products do not fade);

- polyvinylidene fluoride (PVDF) - gives the product high resistance to most external factors and significantly increases the durability of operation.

Important! If for galvanized steel the external polymer coating performs the function of increasing corrosion resistance, then on the aluminum base a layer of polymer is applied exclusively for aesthetic purposes - to imitate wood.

Siding based on cement mixtures

Siding based on cement binder is also presented in two main areas:

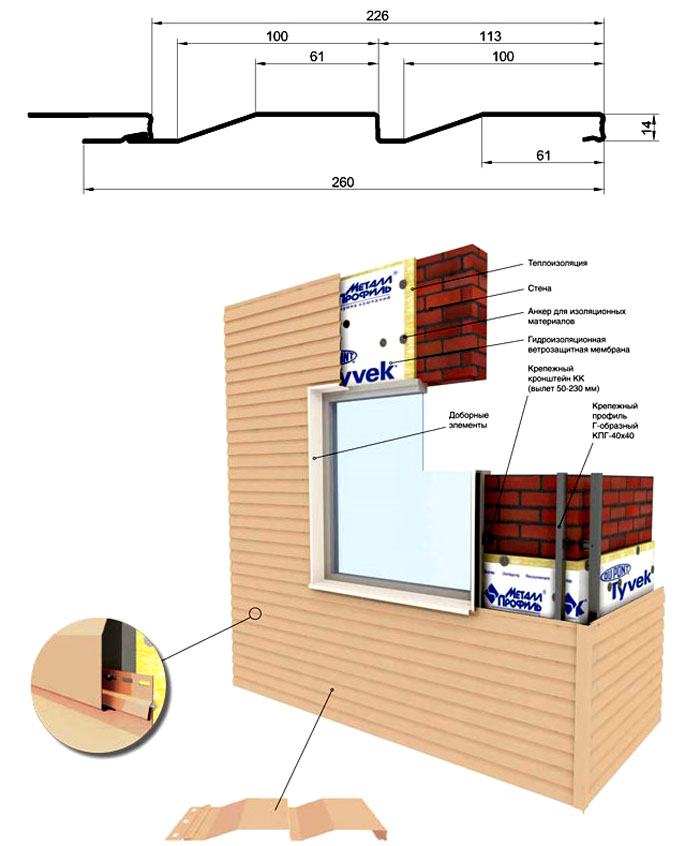

- Fiber cement - the raw materials for the production are cellulose fibers, fine sand, mineral additives and Portland cement M400-600. The texture of wood is applied to the surface. Typically, this finish requires additional painting. As practice shows, staining should be carried out at intervals of once every several years. This finish is produced in the form of rectangular planks that do not have additional locking joints.Fiber cement siding is characterized by a rather high weight and requires not only a more durable lathing, but also, in some cases, additional strengthening of the supporting structures.

- Ceramosiding - the newest of all types of siding. Developed in Japan, it is a material similar in characteristics to ceramic tiles. Fiber cement mixture, kaolin clay and other modifying components are used as raw materials. Unlike ceramic tiles, installation is carried out using special metal holders with screws. It has almost ideal operational and aesthetic characteristics, but its cost is the highest of all the listed types of siding.

Wood

Traditional solid wood finishing materials are quite expensive and demanding to operate. Under the influence of the environment, the wood mass is susceptible to warping, cracking, rot, fungus, damage by woodworm beetles. To prevent these negative phenomena, a coating was developed based on composite materials: wood-pulp, carbide resins and polymer compounds. This type of finish is actually made from waste from the wood industry, therefore it has a budgetary cost. The performance characteristics of this material are not high enough, therefore, preference is usually given to other types of finishes.

Related article:

Siding "brick" and "stone": varieties, their main characteristics, advantages and disadvantages. The main manufacturers, the most popular collections, the sequence of installation work.

Basic types of profiles

There are several types of siding, which are distinguished by the shape of the profile.

- Ship board - a profile in the form of a quadrangle, one of the ends of which is beveled at an acute angle. This form is widely used in both polymer and metal types of siding. Differs in the presence of easy-to-install and hermetically sealed lock joints that greatly facilitate the installation process Designed for horizontal laying, which completely excludes moisture seepage from rain under the cover.

Schematic representation of siding with a "shipboard" profile. Features of its laying on the working surface

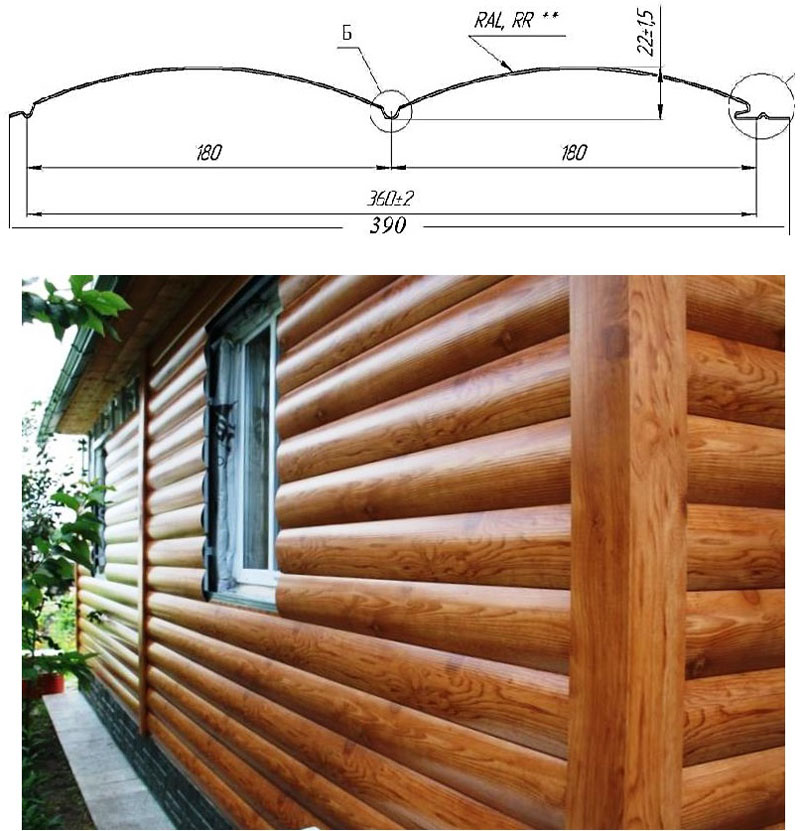

- Block house (log siding) - the profile imitates the outer semicircular edge of a rounded log. This type of profile is used in metal, polymer and wood types of siding. As a rule, they try to give the cladding a look as close as possible to natural materials, including the texture and color of the wood. Used for horizontal installation. Metal and polymer siding has locking joints and holes for fastening. Wood composite cladding is installed in a tongue-and-groove connection.

- Herringbone - is a triangular profile with a stiffener from an additional bend, located so that two wedges are formed on one panel. Made from metal or polymers. Designed for horizontal installation. The lock connection ensures the tightness of the structure.

- Rectangular - a profile in the form of a simple rectangle is used in the production of fiber cement siding and ceramic siding. Fastening is carried out either directly through the cladding, or using special fasteners.

Advantages and disadvantages of using

| Parameter | Polymer siding | Metal siding | ||

|---|---|---|---|---|

| Vinyl | Acrylic | Steel | Aluminum | |

| Weight | Small | Small | Average | Average |

| Does not require reinforced lathing and strengthening of the supporting structures of the structure; installation at a height of up to 2-3 floors is allowed | Reinforced (more frequent) lathing of wooden beams with a thickness of at least 50 × 50 mm² is required; installation on 1-2 floors | |||

| Corrosion resistant | High | Medium, provided that the integrity of the anti-corrosion layer is preserved | High | |

| Resistant to biological corrosion | High | High | ||

| Resistant to chemicals | Medium, susceptible to some solvents | The base is highly resistant, the external anti-corrosion (decorative) coating can be damaged by some solvents | ||

| Fade resistant | Average | High | Medium to high, depending on manufacturer | Medium, practically has no embossed texture |

| Imitation of natural materials | Average | High | Medium to high, depending on manufacturer | Medium, practically has no embossed texture |

| Technological fastening and ease of installation | Fast, convenient, technological fastening | Fast fastening, secure connection, time consuming material cutting | ||

| The need for post-processing | Not necessary | |||

| Repair suitability | Replacement required if damaged | |||

| The cost | Low | Average | Low | High |

Table continuation

| Parameter | Siding | Wood | |

|---|---|---|---|

| Fiber cement | Ceramosiding | ||

| Weight | Large | Large | Average |

| When facing large areas, additional strengthening of the supporting structures is required | |||

| Corrosion resistant | High | High | |

| Resistant to biological corrosion | If organic matter gets into cracks and grooves, moss may appear | High | Low, requires systematic antiseptic treatment |

| Resistant to chemicals | The outer paintwork may be damaged | High | Average |

| Fade resistant | Average | High | Low to medium, depending on the paints and primers used |

| Imitation of natural materials | High | High | |

| Manufacturability of fastening and ease of installation | Medium, the material is quite heavy | Average, despite the presence of special fasteners | Average |

| The need for post-processing | Frequency of coloring once every 2-3 years | Not necessary | We recommend painting once every 1-2 years. |

| Maintainability | You can cover the damage with cement | Replacement required | You can cover up the damage with special mastic |

| The cost | Average | High | Low |

Despite the big difference in basic performance characteristics, all types of siding have common positive features:

- affordable cost compared to natural materials;

- durability - the service life, in accordance with the assurance of the manufacturers, ranges from 25-50 years;

- environmental friendliness - even polymer siding does not have a negative impact on human health. During operation, they do not emit carcinogenic substances, the unpleasant odor disappears some time after installation;

- the shape of the profile allows for quick and easy installation, while the joints will be reliable and tight.

Selection features

After analyzing the data from the table, we can come to the conclusion that the key criteria on which the choice of siding "under the tree" is based are the following.

- Resistance to external influences. In this case, the features of the choice of material depend on the type of external influences, that is, the location of the structure in a certain climatic zone. In the southern part of Russia, it is recommended to use siding that is resistant to high temperatures: acrylic, wood, cement-based, metal.In the northern part of the country and in the Far East, the main factors of influence are low temperatures and high humidity, therefore, it is advisable to use acrylic, metal and fiber cement siding for facing facades. If the structure is located near the sea or along highways with heavy traffic (high concentration of mineral salts and chemicals), it is best to use polymer siding.

- Cost. Even among the finishing materials of the same type, the price can vary significantly depending on the manufacturer. The most expensive are products from Canada, Finland and Germany. However, the cost of products of many domestic manufacturers is much lower with a comparable level of quality.

- Durability. Under the same operating conditions, the most durable is ceramic siding, fiber cement and metal. Due to the high safety factor, they withstand significant temperature drops, mechanical external influences and other aggressive operating factors. It is recommended to use polymer siding in places with a low probability of mechanical stress.

Installation technology

For installation work on the installation of siding, you will need the following tools:

- level;

- roulette;

- scissors for metal;

- hacksaw;

- screwdriver with attachments;

- drill (hammer);

- Bulgarian.

As consumables, depending on the type of siding, ordinary screws are used, alone or in combination with special fasteners.

Important! It is not recommended to cut the polymer or metal siding with a grinder. By cutting through the metal, the cut-off wheel heats it up, damaging the outer anti-corrosion coating. And polymers can deform under the influence of temperature.

Siding installation begins with the installation of the starting bar. It is mounted at a height of 30-40 cm from the lowest point of the house in relation to the ground level. It is necessary to set the starting bar absolutely horizontally, the quality of all the work depends on it.

In the event that the finishing of the foundation or basement floor protrudes beyond the siding, it must be installed above the basement drain bar.

If complex additional elements are used during the installation process, then they are installed in the appropriate places immediately after fixing the starting bar.

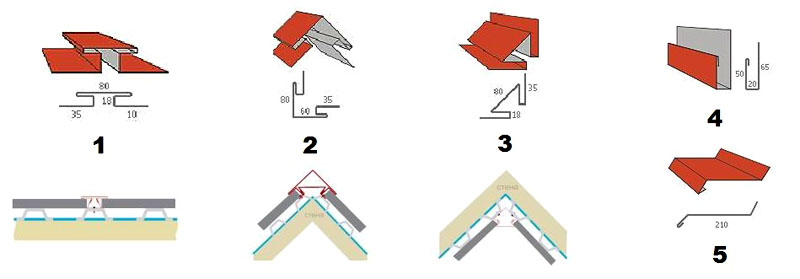

Complex additional elements and features of their installation:

- The H-connector is complex.

- Outside corner difficult.

- Internal hard corner.

- Slope strip or platband.

- Low tide bar.

The installation of ordinary strips can be carried out around the structure or each wall can be trimmed separately. An ordinary strip of siding is inserted into the vertical grooves of the additional elements and lowered onto the starting bar. It is necessary to bring it into the lock connection until it clicks. Do not use a hammer or otherwise mechanical force on the siding. With a correctly set starting plate and additional elements, the ordinary strip will go into the lock connection quite easily.

Horizontality is checked. Further, the strip is fixed with a screw strictly in the center of the mounting holes. Sequence of fastening from the center to the edges to prevent the formation of waves. All subsequent planks are installed in the same way.

Related article:

DIY siding installation: instructions for dummies with photos, the benefits of using panels and their varieties, tips and tricks - in our publication.

Calculator for calculating the amount and cost of siding per home

Useful video

Installation of fiber cement siding:

Installation of acrylic siding:

Installation of siding under a log:

Gallery

Block house siding:

Siding trim "ship board" and "herringbone":

Ceramic siding and fiber cement siding:

conclusions

Siding is an affordable finishing material that can be used to transform even an old building. An additional advantage is the ability to do the finishing with your own hands, which will significantly reduce the overall repair costs. However, you should not save a lot by purchasing dubious products from unknown manufacturers.