How to lay linoleum: everything a master needs to know

Despite the presence many modern floor materials, linoleum continues to be one of the most popular. The reason is in the successful combination of affordable cost, strength and manufacturability of laying. In addition, progress does not stand still, and manufacturers continue to develop new types of linoleum that are distinguished by high aesthetic performance and durability. In this article, we will provide comprehensive information on how to lay linoleum on various types of coatings, compare the possibility of using a variety of fasteners. We will also give advice on how to properly carry out the preparatory work.

The content of the article

Laying linoleum - general requirements

Before starting work on laying linoleum, it is necessary to analyze the condition of the floor surface. Depending on the presence and type of irregularities, as well as existing damage, repair work may be necessary up to pouring a new screed... If the defects are insignificant, but still present, you should choose the type of linoleum with a compensating substrate.

If the area and dimensions of the room allow, then it is better to purchase a piece of material that would cover the entire room as a whole, without joints. This will greatly facilitate the work and make the result better.

Turning to the store, show the consultants a pre-prepared floor plan with all dimensions. Especially if the room has a standard configuration. It is better if professionals independently calculate the required dimensions and determine the shape of individual pieces of linoleum.

Important! It is not recommended to use linoleum as a floor covering if there is a risk of dampness of the base. The moisture content of concrete on the floor of the base or cement-sand screed should not exceed 5%, floors made of solid wood, plywood or OSB - no more than 10%. Also, for most types of household linoleum, the room temperature should not drop below + 10 ° C.

The store provides the widest selection of flooring, do not hesitate to approach a consultant for advice

PHOTO: pol-exp.com

Related article:

What linoleum to choose for home: types of flooring, sizes, markings, criteria for choosing the right room by room, tips and tricks - in our article.

Preliminary work

Before starting work on laying linoleum, it is necessary to draw up a floor plan of the room, choose the type of linoleum and the optimal way of fixing it, purchase the necessary fasteners, consumables and missing tools. It is advisable to inquire on the Internet about the quality of the products of the selected linoleum manufacturer.

How to take accurate measurements correctly

The configuration of the room is transferred to paper on a scale indicating the main dimensions and taking into account the location of doorways, niches, protrusions, etc. If there is a good scheme, for example, in a house book or project documentation, it is better to make a photocopy of it. Unfortunately, the dimensions indicated in the plan may seriously differ from the real ones. Therefore, it is necessary to additionally perform a thorough measurement of the entire room.

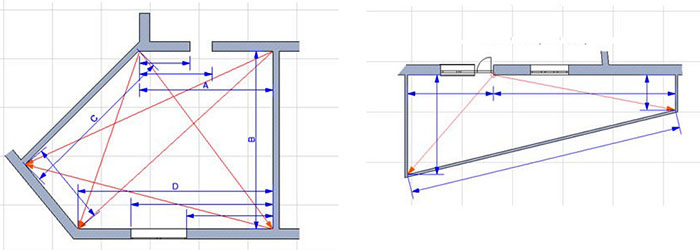

Of particular difficulty for inexperienced craftsmen is the measurement of rooms with a complex configuration. To determine the area of such rooms, they are divided into triangles with vertices in the corners of the room. After that, in one of the many online calculators, the area of these triangles is calculated using Heron's formula (on three sides).

Features of the choice of material (briefly)

The choice of linoleum is carried out according to the following criteria:

- durability class - for domestic premises, the durability of coatings from 21 classes is quite enough;

- composition - homogeneous or heterogeneous;

- manufacturers - Forbo, Tarkett, Grabo, etc .;

- the presence of a high-quality front protective film. If the material is strongly bent, it does not crack or whiten at the bend;

- decorative qualities.

In accordance with the type of linoleum purchased, it is necessary to select an adhesive composition or other fastening materials. For example, a felt or jute-based coating is braided with mastic spread by a notched trowel. Linoleum with a backing of polyethylene or PVC foam is attached to double-sided tape. If there are joints, you must purchase a cold welding adhesive.

Tools used

What's more good about linoleum is that for its installation you need a minimum amount of tools, which, moreover, is inexpensive. For independent work you will need:

- level - it is better to take 1.5 m;

- long and short metal rulers - a long one (by 2 m) can be replaced with an aluminum rule;

- construction knife with a set of replaceable blades;

- consumable fasteners:

- Double-sided tape;

- glue or mastic;

- cold welding for seams.

Important! If you have a large amount of cutting work, it is better to purchase a special roller knife or scissors with replaceable blades.

Foundation preparation

Preparing a justification is one of the most important stages of linoleum laying, on which the quality of the final result largely depends. Consider the thickness and type of substrate. Felt and jute slightly smooth out small defects (up to 1.5-2 mm), homogeneous coatings, cork and foamed polyethylene substrates require a perfectly flat and clean surface.

The result of poor base preparation is a relief that will wear out in the future.

PHOTO: krovati-i-divany.ru

Concrete, cement-sand and cement-polymer screeds

Linoleum almost never fits on the floor slab, its surface has too many defects. It is allowed to lay thick felt-based linoleum on rough cement-sand screeds. A thin coating sensitive to defects can be laid on self-leveling cement-polymer screeds, the so-called levels.

It should be remembered that the drying period of the cement-sand screed from the moment of pouring to the moment of laying is at least a month, and for the cement-polymer screed - about a week. During the work, the ambient temperature should not be lower than + 12 ° C, and the moisture content of the base should not exceed 4%.

Board, chipboard, plywood, OSB

Most often, the designation "laying linoleum on a wooden floor" means a rough base from an array of boards. Such a surface is covered with plates Chipboard, OSB or plywood at least 10 mm thick... The plates are fastened with anti-corrosion coated screws. During screwing, the caps are completely recessed into the surface of the slab, and the attachment point and the cracks between the slabs are covered with a special putty for wood.

Carpet, linoleum

Both types of flooring cannot be used as a basis for laying linoleum. It is strongly recommended to dismantle them, remove the remnants of glue, eliminate the defects of the rough base formed as a result of operation.

Ceramic tile

Loose tiles are fixed, all chips and gaps between the tiles are sealed with putty. The front surface of ceramic tiles has low moisture absorption, therefore it is necessary to use an adhesive with a high adhesion... In case of a large number of defects, the surface is filled with a polymer-cement leveling with a thickness of at least 3 mm.

How to lay linoleum - laying technologies

After the linoleum roll is delivered to the room, it must be rolled out and allowed to rest. In winter, it is necessary to maintain an additional pause to allow the material to heat up. Subzero temperatures have an extremely negative effect on the strength of polymers. It is advisable to leave the coating unfolded overnight, and ventilate the room, so the surface will smooth out and the concentrated chemical smell will evaporate.

Roll out linoleum carefully. Material like the one in the photo won't last long

PHOTO: stroimsami.online

Cut

When cutting a linoleum canvas, you must adhere to the following rules:

- A covering with a plain surface should be cut in such a way that the resulting joints are parallel to the light flux from the windows. So they will be less noticeable, and the coating will take on a monolithic appearance.

- If there is a pattern, it should be placed parallel to the outer wall of the room. Cutting should take into account the pattern and make it match.

- If two canvases are needed to cover the entire area of the room, it is not recommended to join them in the middle of the room. The seam forms a kind of "equator" that will be very noticeable. For a kitchen and a hall with a furniture wall, it is better to make 2 joints that can be masked with furniture.

- Recesses for communications (heating pipes, water supply, etc.) and protruding structural elements can be cut out on site only after the material has fully acclimatized. At the same time, it is desirable to maintain a temperature of 20-25 ° C in the room so that the polymer becomes soft, but does not undergo excessive thermal expansion.

- For especially complex cutouts, you need to make cardboard cutouts.

Dry styling

Laying linoleum without glue is used in residential premises with an area of no more than 20 m². As a rule, one sheet is enough for such rooms. A roll of cover is rolled out indoors, and a preliminary cut is made in such a way that the overlap on each wall is 8-10 cm.

After the linoleum has rested, after about a day, the final fit is made. The excess coating is cut off 5-10 mm from the wall edge. For an even cut, a metal ruler and a knife with replaceable blades are used. It is recommended to change the knife blades more often to make the fit neatly.

Video instruction for the dry method of laying linoleum

Laying on glue

Linoleum is glued in rooms with an area of more than 20 m², with intensive use of the floor covering or when using several pieces of material. It is also recommended to glue the cover if it is planned to periodically move heavy objects and furniture in the room. Loose linoleum with such operation is guaranteed to go in folds.

Manufacturers of this finishing material always prescribe the required brands of glue in the accompanying documentation or on the packaging and give recommendations for its use. All adhesives can be roughly divided into three main groups:

- PVA (Polyvinyl Acetate) is a versatile adhesive used to attach most brands of linoleum. It is reliable and durable enough, has an affordable cost. It has a mild unpleasant odor that will take a long time to disappear. It is characterized by low moisture resistance and resistance to biological damage.

- Synthetic latex-based compounds (gumilax or syntolax mastics, bustilat glue). Non-toxic, practically odorless, or it quickly erodes, moisture resistant. Some brands contain bactericidal and plasticizing additives.

- Water-dispersive (homakol, forbo). They are mainly used for household use. Used for fixing linoleum, carpet, cork coverings.

Important! To increase adhesion, it is recommended to treat the surface of the base with a 15% solution of Bustilat glue.

After processing the base with a primer and preliminary cutting of the canvases, part of the spread linoleum is rolled up, and glue (with a roller or brush) or mastic (with a notched trowel) is applied to the base surface. The coating gently unfolds back, while air bubbles are expelled from under the linoleum with plastic spatulas. The glued part is smoothed with a rag or rolled with a special roller.

The same procedure is done with the second part of the canvas. The final trimming of the wall covering is done in a similar way to dry installation. To trim the inner corners, a radial cut is first made, and then the coating is tucked into the corner.

The largest piece of cover is fixed first. Smaller canvases are laid on it with an overlap of at least 5 mm and taking into account the coincidence of the pattern. A ruler is applied to the intersection of the canvases and both layers are cut.

Related article:

How to choose glue for linoleum: advantages and disadvantages of use, classification of adhesive mixtures, their area of application, leading manufacturers and brands of glue, sequence of actions for self-laying linoleum.

Video: features of the choice of linoleum and the technology of laying on glue

Welding seams

The joints between linoleum canvases are the weakest point of the entire floor covering, therefore, several technologies are used to strengthen them:

- Cold welding... It is an adhesive composition that is applied to the coating surface. Designed for household use. It is of two types:

- For welding immediately after laying. Has a more liquid composition, melts linoleum polymers, chemically combining them together.

- For the repair of surfaces that have already been used and the seam has come apart. The consistency is pasty. It not only holds the two parts of the coating together, but also fills the seam.

The working surface must first be degreased. Stick masking tape along the joint on each side at a distance of 1-2 mm from the joint. Then cold welding is applied precisely to the seam.

- Hot welding... For use on homogeneous commercial linoleums. The cutter cuts a groove along the entire length of the seam. The polymer cord is welded into the seam with a special hairdryer with a nozzle. After cooling, the protruding part is cut off with a scraper.

High-quality linoleum in the interior:

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

- PHOTO: dekoriko.ru

Plinth installation

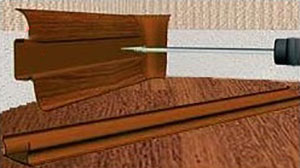

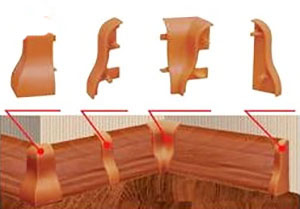

Plinth installation is the final stage of linoleum laying. It closes the gap between the flooring and the wall, protecting the ends of the linoleum from moisture and dirt. Most often, plastic skirting boards are used, consisting of a base and a decorative strip. Installation of such a plinth is carried out as follows:

Summing up

Linoleum is one of the most technologically advanced floor coverings. Its installation can be done independently, with absolutely no experience in such work, without purchasing expensive tools. To get a good result, you just need to follow the advice and carefully measure the material before cutting.

If the article turned out to be useful to you, take part in its discussion and subscribe to our newsletter.