What is wallpaper glue: types, choosing the right composition, reviews

Purchasing quality stylish wallpaper is only the first stage of renovation work. The second, no less important step is the selection of the appropriate adhesive composition. In this article we will talk about what kind of wallpaper glue is, types and choices in accordance with the type of finishing material and area of application. We will describe the main characteristics, advantages and disadvantages of specialized and universal adhesive mixtures, as well as acquaint our readers with reviews of some popular brands.

The content of the article

Requirements for wallpaper glue

Regardless of the composition and purpose, all adhesive mixtures must meet the following requirements:

- high adhesion - initial and final. The ability of the glue to hold still wet wallpaper on the wall (with the possibility of their correction), and after drying determines the strength of the connection of the finishing materials and the base;

- consistency and viscosity of the composition allows you to apply it with a roller, brush or special devices with a layer 0.3-0.8 mm thick;

- curing rate, in the range of 10-30 min. This will allow for a thorough adjustment of the wallpaper panels;

- tensile strength in a day, not less than 0.1 MPa, in three days (after complete drying) - not less than 0.3 MPa;

- low sensitivity to moisture... When washing or operating in damp rooms, the adhesion strength should not decrease by more than 20% of the indicators declared by the manufacturer;

- acidity... It is advisable to purchase adhesives with a neutral acid-base pH = 6 ... 7. Their use reduces the risk of yellow staining on light-colored paper wallpapers.

The result of choosing the wrong brand of glue or violations in the technology of its use

PHOTO: 124mastera.ru

Related article:

Wallpaper for walls: photo catalog interesting solutions for the living room, bedroom, children's room, kitchen and corridor.The basic rules for the selection of paintings and recommendations of designers - read our review.

The composition of wallpaper glue and its classification by purpose

Any glue for wallpaper consists of three main components, the percentage of which varies based on the purpose.

The foundation - is 50-100%. Typically dry material in the form of flakes or powder, which, when diluted with water, forms a viscous and sticky transparent mass. Most manufacturers use two types of materials as a base:

- Modified starch (MK) and its derivatives (carboxymethyl cellulose "CMC", carbomethyl starch "KMK", hydroxypropyl starch "HPA").

- Methylcellulose "MC".

PVA (Polyvinyl acetate) - it accounts for 0-50%. Active additive that increases the final adhesion.

Bioactive additives (bactericidal and fungicidal) - no more than 3%. Prevents the formation and spread of mold and mildew.

As a rule, manufacturing companies indicate the purpose of the adhesive directly on the packaging. The names also contain the designations “universal” and “special” indicating the type of wallpaper for which it is intended.

Despite the wide variety of brands, the composition of most brands of wallpaper glue is 90% the same

PHOTO: remontami.ru

For light wallpaper (normal)

By light we mean paper wallpaper in one layer (simplex) and two layers (duplex). The second option is more resistant to external influences - humidity and ultraviolet radiation. The basis of the adhesive composition "KMTs" and "MK". Reinforcing additives (PVA) are practically not used. For paper wallpapers, general-purpose adhesives with a less concentrated solution can also be used. The liquid consistency allows better impregnation of the finishing material, thereby achieving a higher adhesion to the substrate.

For gluing one and two-layer paper wallpaper, universal adhesives with a lower concentration are usually used.

PHOTO: images.ua.prom.st

Related article:

How to glue wallpaper: choice of tools and glue; gluing in difficult places: at corners, around windows and behind batteries; how to glue different types of canvases: paper, non-woven, vinyl and self-adhesive; how to select a pattern and mask seams.

For heavy wallpapers (universal and special)

The composition includes PVA (up to 25%). It is usually sold in the form of dry mixtures that require dilution with water. The concentration depends on the type of wallpaper and is indicated on the package. Used for gluing the following types of finishing materials:

- vinyl;

- textile;

- acrylic;

- structural (for painting);

- metallized.

For gluing expensive heavy wallpaper, it is better to use specially developed adhesives.

PHOTO: mr-build.ru

Related article:

How to glue paper backed vinyl wallpaper. The secrets of high-quality gluing of vinyl canvases on a paper basis in a separate publication of our portal.

Dispersed compositions

They have the highest adhesion properties. They contain 25-50% PVA and other additives. They are used for gluing heavy and "special" tapestries:

- with a foam, embossed and textile outer decorative layer;

- non-woven for painting;

- laminated (with a protective acrylic coating);

- on a fiberglass basis.

Specialized

Bamboo, cork and some textile wallpapers require special adhesives. Neoprene and acrillate additives act as an additional binder. Typically, these formulations have a viscous consistency and are applied with a spatula.

Release form

All existing types of wallpaper glue are available in two versions:

- Dry mixes. The main volume of the adhesive (base) is modified cellulose.Depending on its type, the preparation of the composition requires water of different temperatures, which can be viewed on the packaging or on the website of the manufacturer.

- Ready-to-use formulations. Factory preparation method - control of external conditions and precise dosage make the adhesive mixture more effective. Such grades are used for fastening trellises that require special installation conditions.

Important! Adhesive for non-woven wallpaper, as a rule, stands out in a separate category, since it is applied directly to the wall and must withstand a technological pause of about 10 minutes to penetrate deeper into the base material.

Related article:

How to paste wallpaper on wallpaper. Option for gluing non-woven, liquid and vinyl coatings; what kind of glue is better to use, how to prepare the surface, how to glue the canvas to the ceiling, how to process corners - read our publication.

Selection criteria for wallpaper glue

When choosing an adhesive mixture for wallpaper, it is most advisable to be guided by the following initial data:

- weight and type of base of the finishing material;

- base material (usually walls);

- operational characteristics of the premises: humidity, temperature, dynamics of change;

- additional parameters: the threat of mold and mildew, the need for systematic wet cleaning of the walls, etc.

Manufacturability... Determines the ease of use of the adhesive mixture. The effective concentration should give the consistency of the working mixture, which makes it easy to apply the glue with a brush, roller or special apparatus to the surface of the wallpaper or wall. At the same time, the edges of the finishing materials should not curl, and the adhesive mixture should show through on the front side. During work, the glue protruding from the joints should be easily removed with a damp cloth, without leaving any marks on the front surface, including after drying.

Mobility... A parameter that determines the ability of the adhesive to slide on the surface of the base. The high mobility of the newly applied adhesive mixture determines the possibility of a more accurate and thorough adjustment of the finishing material. This is especially important for photo wallpaper and wallpaper with a complex compatible pattern.

Moisture resistance and recoverability of adhesion... Determines the ability of the adhesive to soften when exposed to excess moisture on the front of the finishing material, and after drying, restore the adhesion to the base.

The negative effect of moisture on the wallpaper is manifested primarily at the joints

PHOTO: smartsoft.ru

Long term... The ability to keep the finishing material on the surface of the base in its original form, without the formation of blisters, wrinkles, cracking and divergence of joints.

The output of a useful substance... Not critical, but an important parameter that determines the volume of repair costs.

Ready mix life span... You should pay attention to this parameter if wallpaper is glued on its own in several stages. As a rule, the prepared mixture can be stored in a tightly closed container for up to several weeks without losing its characteristics.

This is what a ready-to-use adhesive for non-woven wallpaper looks like after mixing and a technological pause for ripening

PHOTO: krrot.net

Calculation of the need for glue per 1 m²

It would seem that the consumption of wallpaper glue is quite simple to determine. The required value is always indicated on the package. However, there are factors that can significantly increase or slightly reduce the amount of adhesive used.

Substrate surface finish... The wall should be finished with a finishing putty, which forms an even, smooth and dense layer. The putty must be coated with a deep penetrating acrylic primer twice. This will reduce the absorbency of the material.Some manufacturers recommend using glue diluted in the appropriate proportion as a primer.

Important! If the adhesive mixtures are applied to an untreated base with a primer, they will not only be absorbed into it, which will cause overruns, but will also dry out quickly, which will significantly reduce the strength of the connection between the wallpaper and the wall.

The type of wallpaper and the method of gluing them... The technology of gluing some types of wallpaper requires applying glue only to the panel (most paper), others only to the base (non-woven). There are types of wallpaper that require glue to be applied both to the panel and to the base (based on fiberglass and some vinyl). The amount of glue purchased must be adjusted accordingly.

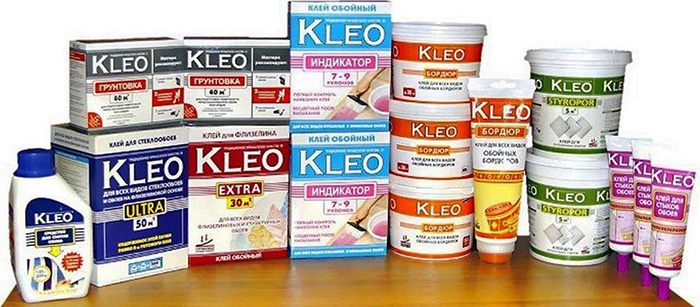

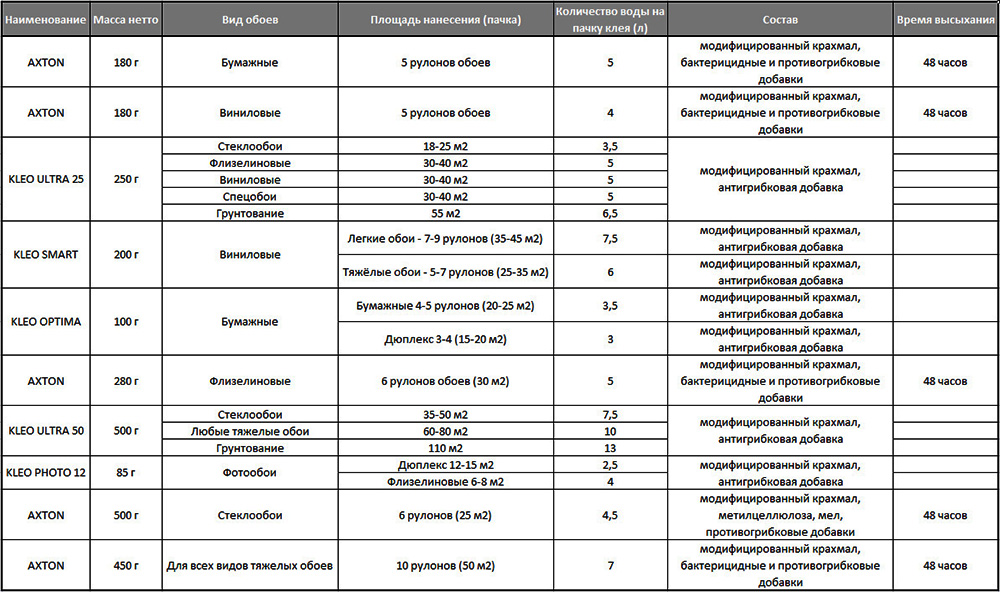

Table of consumption standards for some brands of glue, depending on the type of wallpaper

PHOTO: domdvordorogi.ru

Determining the amount of glue required is quite simple. The area of the walls is calculated, the space of window and door openings is subtracted from it. The resulting value is adjusted up or down, depending on the factors indicated above.

Brand manufacturers

The modern building materials market offers a wide range of brands of wallpaper glue. Some manufacturers position their products in the budget price segment as a universal composition suitable for gluing wallpaper materials of any type. At the same time, they promise high adhesion rates in harsh operating conditions. However, experienced craftsmen are strongly advised to trust only trusted manufacturers.

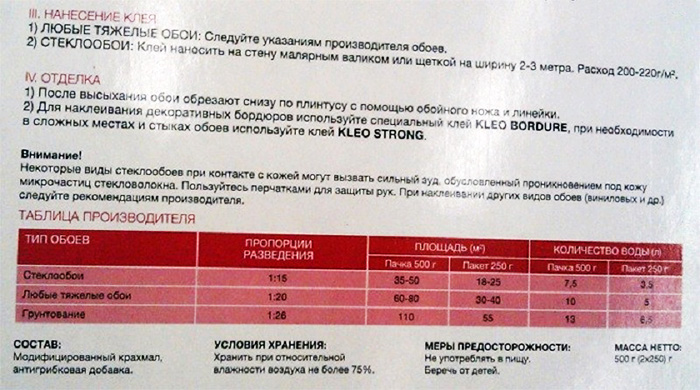

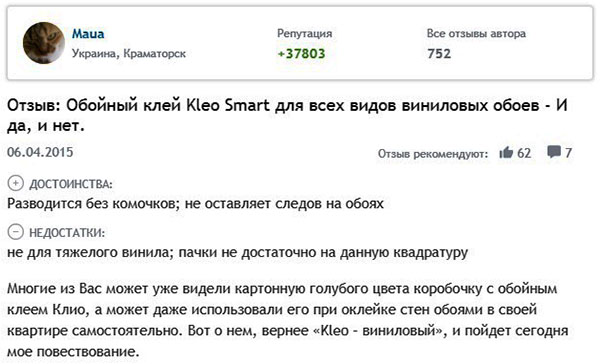

KLEO (France)... A trade mark under which universal and specialized adhesive mixtures are produced. The “Cleo Extra” line of adhesives for heavy structured wallpapers is especially popular. It is produced in the form of a dry construction mixture. It is quickly diluted with water and is ready for use in a few minutes. Ready-made solutions are usually transparent and invisible on the surface. It also contains highly effective fungicides that reduce the risk of fungal growth. The finished mixture is suitable for use for 10 days.

Methylane (Germany)... Offers a full line of adhesive mixtures used for gluing all types of wallpaper. Provides extra strong adhesion to mineral surfaces: plaster, concrete, brick... For several minutes, it allows the strips to slide, facilitating their placement on the surface.

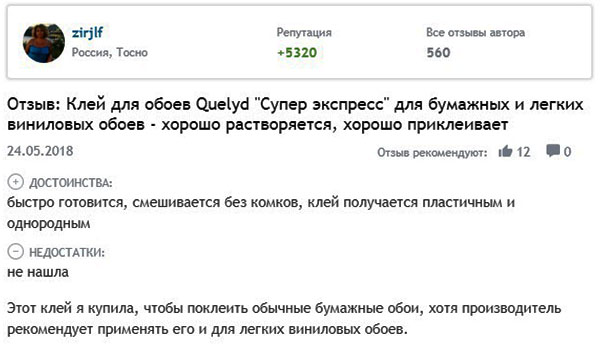

Quelyd (France)... Designed for gluing heavy structured wallpaper, including non-woven for painting. The ripening time of the mixed solution is at least 10 minutes. The mixture is applied to the working base (wall). The surface is paintable after 24 hours. It has good adhesion, however, it can be easily removed from the substrate with a spatula.

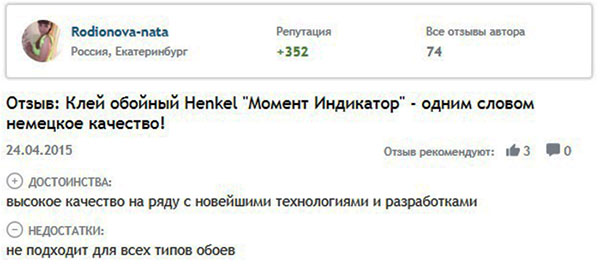

Moment (Henkel Germany)... Highly adhesive composition based on methylcellulose. The cooking time is at least 15 minutes, the shelf life of the finished composition is up to 7 days. It also contains a variety of fungicides and antiseptics. Recommended for use in rooms with high traffic (hallway living room) or high humidity (kitchen).

PUFAS (Germany)... Universal glue, which, depending on the concentration, can be used for gluing the entire list of wallpaper materials. Ready time when dissolving is not earlier than half an hour. Provides good adhesion to concrete, plaster and brick substrates, as well as wood and drywall.

Reviews on the use of different brands of glue

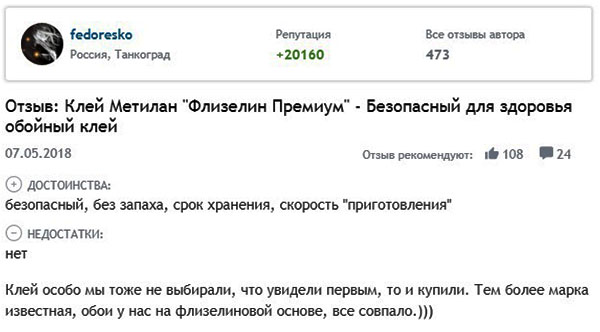

Feedback on the use of Methylane Glue "Flizelin Premium":

Feedback on the use of Henkel wallpaper glue "Moment Indicator":

Feedback on the use of Quelyd "Super Express" wallpaper glue for paper and light vinyl wallpapers:

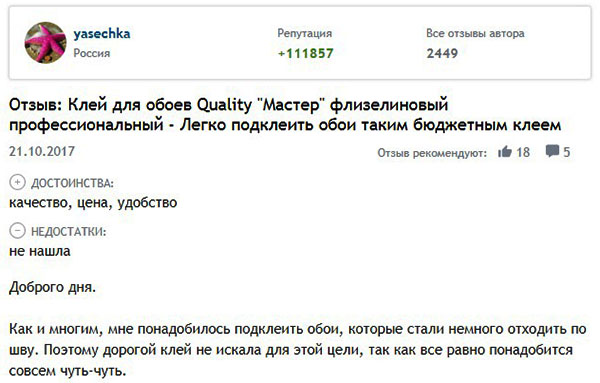

Review of Quality "Master" wallpaper glue, non-woven, professional:

Review of Kleo Smart wallpaper glue for all types of vinyl wallpaper:

conclusions

Wallpaper is a technological and very common finishing material. Some of their varieties are quite expensive. Therefore, it is necessary with special care to select the adhesive composition in order to avoid delamination and other negative consequences.